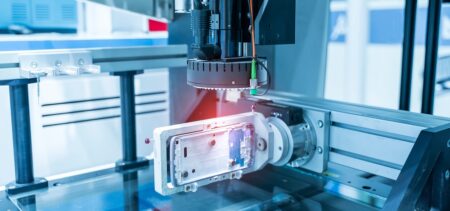

Porsche AG has developed a new production process at its headquarters in Zuffenhausen, Germany in collaboration with Tesa SE. Using this process, the holes in the car body, which are necessary for corrosion prevention, can now be sealed much more effectively; these holes are required so that all of the body cavities can be accessed in the paint shop. The innovative solution: sealing patches instead of plastic plugs. The all-electric Porsche Taycan is the first car in the world to use this new process. A robot places more than 100 sealing patches automatically, quickly and reliably, thereby sealing the holes in the body and optimising efficiency in Porsche production.