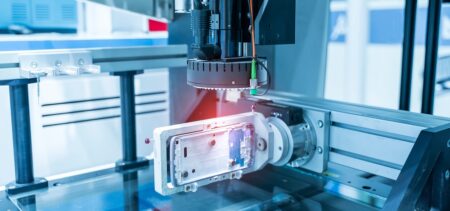

Work holding fixtures for inspection devices have evolved over time and now have become, in some cases, as complex as the parts they are designed to hold. There was a day when some 1-2-3 blocks, knee blocks, double-sided tape and hot glue were all you needed to fixture parts for measurement on a coordinate measuring machine (CMM). Today’s world of ever-shrinking tolerances, more complex geometries and demanding production schedules requires a much more sophisticated approach to fixture design.

Back when CMM programs were stored on 3½ inch floppy disks, not much consideration was given to proper part constraints, datum simulators and gaging system variance or repeatability.