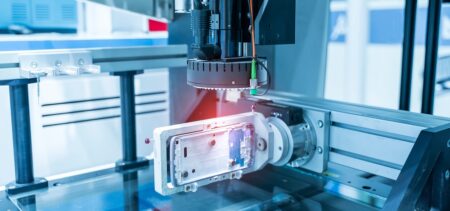

When problems occur on a production line, the cause can often be difficult or impossible to identify. Mechanical errors can happen so quickly that it’s impossible for staff to intervene before there are interruptions, shutdowns, or wastage. When a line is producing at a cycle rate of, say, 100 pieces per minute, the human eye and brain simply can’t see or compute what’s going wrong.

As a consequence, at one time or another most plant operators will find themselves faced with the same puzzling questions: are production line glitches a consequence of tools or equipment wearing out, or products or operators on the line changing, or machine operating parameters needing adjustment, or productivity targets simply being unrealistic?