The dawn of a new industrial revolution is upon us, characterized by the seamless amalgamation of two powerful forces: Artificial Intelligence (AI) and robotics. This pioneering partnership is not just transforming manufacturing processes but also redefining efficiency, safety, and adaptability in the industry. As AI and robotics merge, they unlock unprecedented capabilities, enabling manufacturers to navigate through the complex and dynamic world of modern industrial operations with greater ease and precision. This integration heralds a significant paradigm shift, moving beyond the confines of traditional manufacturing to create systems that are not only interconnected but are intelligent, self-optimizing, and capable of making strategic decisions. As we delve deeper into the realms of these technological marvels, it becomes apparent that their synergy is the key to unlocking the next level of industrial prowess and staying competitive in an ever-evolving market landscape.

The Harmonious Relationship of AI and Robotics in Manufacturing

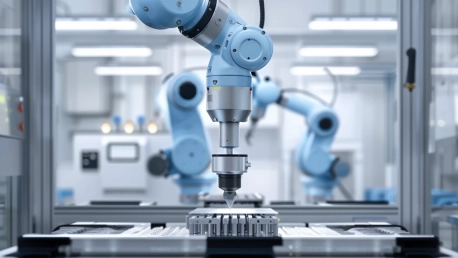

In the intricate dance of modern manufacturing, AI and robotics have become the perfect partners, executing a choreography that drives production to new heights of efficiency. AI serves as the brainpower behind the brawn of robotics, creating a force that surpasses the limitations of human capability. The collaboration of AI and robotics enables machines to perform with remarkable precision and consistency, ensuring that each product reflects the highest standards of quality.The marriage of these technologies has given rise to intelligent robotic systems that are quick to learn and adapt, reducing the time and resources required for production processes. By taking on repetitive and complex tasks, these robots free up human labor for more strategic roles, fostering innovation and creativity in the workplace. The implications of this harmonious relationship extend far beyond mere productivity gains; it portends a future where smart factories are the norm, distinguished by their dynamic and responsive nature.

Optimizing Production with Real-Time AI Analytics

The deployment of AI in the manufacturing sector has opened the floodgates to a new era of real-time production optimization. AI-driven analytics are shaping the future of manufacturing by providing actionable insights that streamline operations and maximize outputs. Through the continuous analysis of production data, these intelligent systems can swiftly adapt to market trends, making predictive adjustments that keep the manufacturing process at peak performance.AI’s capacity to predict and prevent potential disruptions before they impact production is a game-changer, leading to a more agile and responsive manufacturing line. This adaptability not only enhances a company’s ability to meet customer demand but also augments its resilience against unforeseen challenges. Embracing AI analytics translates into a manufacturing strategy that is not just efficient but also anticipates the future, ensuring that businesses remain at the forefront of innovation and productivity.

Achieving Continuous Improvement and Resilience

Continuous improvement, a principle at the heart of lean manufacturing strategies, has found a powerful ally in AI. Traditional methods of identifying inefficiencies often rely on human oversight, but AI brings a level of precision and speed unmatched by any human workforce. By consistently monitoring production processes, these intelligent systems can quickly pinpoint issues and propose optimizations, effectively reducing waste and increasing the quality of the end product.This relentless pursuit of perfection through AI not only raises the standard of manufacturing but also fortifies businesses against the rigors of a competitive market. A resilient manufacturing process that rarely falters or produces defects is not a distant dream but a tangible reality in the age of AI. As a result, AI is not only an asset but a critical component of any company seeking to maintain a sustainable and profitable operation.

Enhancing Speed and Safety Through Automation

In present-day manufacturing, speed is synonymous with success. However, this speed must not come at the cost of safety. AI and robotics, working in close concert, have proven to be the solution to this age-old dilemma. Executing tasks with unerring speed and precision, robots equipped with AI are setting new benchmarks in production while assuming functions that would be hazardous to human workers.The tandem of AI and robotics doesn’t merely boost production speeds; it establishes a workplace culture prioritizing employee safety and well-being. This commitment to safety is becoming a hallmark of modern manufacturing enterprises, showcasing their dedication to not only economic efficiency but also to their most valuable resource – their employees.

Transformative Maintenance with AI

Predictive maintenance, once a complex and often neglected aspect of manufacturing, has been radically transformed by AI. Through continuous monitoring and analysis of equipment performance, AI systems can predict when machines will need maintenance, thereby reducing downtime and extending the lifespan of critical industrial assets. This foresight prevents costly interruptions and ensures the smooth operation of the production line.Investing in AI-driven predictive maintenance is not just about preempting breakdowns; it’s about adopting a proactive approach to the care and management of manufacturing equipment. With AI, manufacturers are able to schedule maintenance at the most opportune times, keeping their operations running efficiently and without unexpected disruptions.

The Necessity of AI and Robotics in Modern Manufacturing

In today’s competitive manufacturing sector, expedience equates to success, but not when it jeopardizes human safety. AI and robotics have emerged as the game-changing duo addressing this conundrum, accomplishing tasks with remarkable pace without sacrificing accuracy. These AI-powered robots are not just accelerating production rates; they’re also assuming roles that would be perilous for workers, thus redefining industry standards.The amalgamation of AI and robotic technology is more than a mere catalyst for greater output. It’s revolutionizing factory floors into spaces where worker safety is paramount. Companies at the cutting edge of manufacturing are merging this technology not only for economic benefit but also to underline their commitment to workforce safety. Today’s manufacturers are embedding a culture that holds their workers’ well-being as high as their production goals. This new approach ensures that the rapid pace of manufacturing goes hand in hand with rigorous safety protocols, reflecting an enlightened approach to industrial productivity.