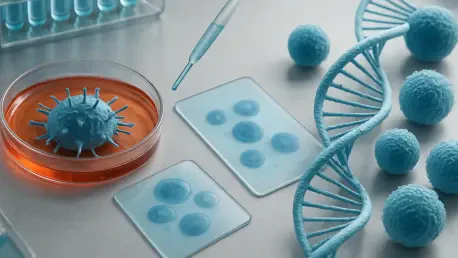

The Promise and Peril of a Medical Revolution Cell and gene therapies stand at the forefront of a medical revolution, offering the potential to cure diseases once considered untreatable. Yet, this groundbreaking sector is caught in a profound paradox. While the science is delivering unprecedented

As India's specialty chemical sector stands at a critical juncture, balancing rapid industrial growth with an urgent need for sustainability and self-reliance, one company is stepping forward with a transformative agenda. Shivtek Spechemi Industries Ltd., the flagship of the Shiva Group of

In a striking display of operational strength, HIVE Digital Technologies announced a massive year-over-year increase in its Bitcoin mining output for January, achieving this milestone even as the global mining landscape became significantly more competitive. The company successfully mined 297 BTC

We are joined by Kwame Zaire, a renowned manufacturing expert whose work in electronics and production management has made him a leading voice on the future of high-tech industries. Today, we'll delve into the seismic shifts in the global semiconductor landscape, exploring Japan’s ambitious

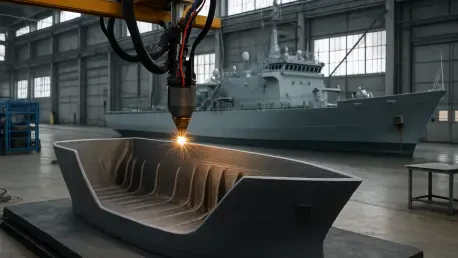

We're joined today by Kwame Zaire, a leading expert in advanced manufacturing and production management, to discuss a groundbreaking development in military logistics. The recent Trident Warrior exercise showcased how deployable metal additive manufacturing, specifically SPEE3D's cold spray

The thunderous roar of a new generation of stealth fighter jets is on the horizon for India, but for the first time, its development may be propelled by the innovation and agility of the nation's burgeoning private industry. In a landmark decision that redefines its defense procurement strategy,

Engineers at the Massachusetts Institute of Technology are confronting two of the planet's most formidable challenges—the escalating plastic waste crisis and the critical need for affordable housing—with a single, paradigm-shifting solution. By pioneering a method to transform discarded, low-value

The Fourth Industrial Revolution has propelled the manufacturing sector beyond incremental upgrades, demanding a fundamental reinvention of how products are designed, produced, and delivered in a globally competitive market. This transformation represents a paradigm shift where digital technologies

The global supply chain, once a model of predictable efficiency, now operates in an environment where constant disruption is the baseline, demanding a fundamental shift toward an infrastructure built on inherent resilience and rapid agility. Building upon the strategic adjustments of recent years,

As the manufacturing world converges on Shanghai, TCT Asia 2026 is poised to offer an exhaustive and in-depth exploration of the entire additive manufacturing value chain, solidifying its position as the largest AM trade show in Asia. This extensive event aims to create a full-chain platform

ITCurated uses cookies to personalize your experience on our website. By continuing to use this site, you agree to our Cookie Policy