The aerospace and defense (A&D) manufacturing industry is undergoing a significant transformation, driven by the integration of artificial intelligence (AI) technologies. Traditional AI and generative AI (GenAI) are revolutionizing various facets of A&D manufacturing by enhancing operational efficiency, quality, and customer-centric processes. The synergy between traditional AI systems and GenAI, bolstered by a wealth of integrated data, is yielding real-world results. The primary effect of this evolution is the substantial improvement in precision, predictive maintenance needs, supply chain optimization, and sales processes. These advancements collectively contribute to the overall transformation of the industry.

As AI technologies become more integrated into A&D manufacturing, they bring about a paradigm shift in how the industry functions. AI’s ability to analyze vast amounts of data and identify patterns and anomalies is key to this transformation. In manufacturing processes, AI systems drive operational improvements by providing insights that enhance planning and forecasting accuracy. The integration of AI-enabled predictive maintenance allows for increased capacity utilization and reduced downtime, further boosting efficiency. Moreover, quality management benefits significantly from advancements in AI-based visual inspections and generative AI, ensuring that any flaws that human eyes might miss are detected promptly. This integration of AI not only improves product quality but also accelerates design changes and remedial actions.

AI Drives Improvements in Manufacturing and Quality Management

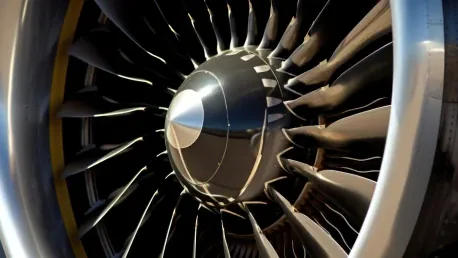

The integration of AI is reshaping manufacturing processes by employing production and business data to drive operational improvements and boost planning and forecasting accuracy. One of the key advantages of AI in manufacturing is its ability to perform predictive maintenance, which significantly increases capacity utilization and reduces downtime. Predictive maintenance involves analyzing data from various sensors and systems to predict when a machine is likely to fail. This allows for timely maintenance, preventing unexpected breakdowns and ensuring uninterrupted production.

AI technologies have also made significant strides in quality management, particularly through the use of AI-based visual inspections. Automated image and video capture systems provide the necessary data for generative AI to detect flaws that human eyes might miss. This capability is invaluable in industries like aerospace and defense, where precision and reliability are paramount. By closing the quality-management loop, AI systems ensure that defects are identified and addressed promptly. Furthermore, generative AI facilitates root-cause analysis and suggests remedial actions, speeding up design changes and enhancing overall product quality. These advancements in manufacturing and quality management underscore the transformative potential of AI in the A&D industry.

AI Boosts Post-Sale Asset Performance Monitoring

Post-sale asset performance monitoring is another area where AI is making a significant impact. By combining machine learning, predictive analytics, and generative AI, companies can enhance performance monitoring and optimize asset management. These AI technologies harness larger datasets to deliver more precise insights and facilitate proactive service execution. One of the key benefits is the optimization of inventory and resource distribution, resulting in reduced spare parts inventory levels and lower transportation costs.

In addition to cost savings, enhanced status reporting, enabled by AI-driven technologies, helps companies develop more creative and profitable business models. In maintenance scenarios, AI runs predictive analyses to prioritize repairs dynamically, allocate resources efficiently, and guide technicians through repairs using augmented reality. This helps field personnel by providing them with accurate and timely information, enabling them to document and detect failure patterns more effectively. Generative AI plays a crucial role in these processes, ensuring that maintenance procedures are continually improved and streamlined, resulting in increased asset reliability and longevity.

AI Tightens the Supply Chain

AI’s role in supply chain management is pivotal in the A&D industry, where the reliability and quality of suppliers are critical. AI significantly mitigates supply-chain risks by meticulously vetting suppliers and understanding associated risks. These AI systems can even predict supplier quality and reliability, providing invaluable insights for defense agencies relying on a secure military-industrial base. The automation of supplier vetting and monitoring processes ensures that vital information is passed on to relevant stakeholders, making the supply chain more secure and reliable.

AI-driven demand forecasting is another area where these technologies excel. By comparing planned versus estimated supplier lead times, AI helps in readjusting schedules to improve production efficiency and minimize disruptions. The benefits extend beyond production to post-sale service parts’ demand forecasting, leading to more responsive and efficient service outcomes. The ability to accurately predict and adjust to supply chain dynamics ensures that the A&D industry can maintain its high standards while minimizing risks and inefficiencies. The automation and predictive capabilities of AI are indispensable tools in achieving these goals.

AI Enhances Customer Centricity and Business-Side Efficiencies

Generative AI tools are revolutionizing the sales process in the aerospace and defense industry by enabling sales teams to produce precise, profitable quotes and proposals. These tools simulate complex equipment and business scenarios, extracting requirement details from unstructured documents. This capability boosts the quality and speed of proposals and quotes while ensuring compliance with government regulations and agreements. The partial or full automation of the sales process not only reduces turnaround time but also enhances the competitive edge of sales teams.

Beyond sales, generative AI extends its applications to various business operations. It aids in contract drafting and monitoring, thereby enhancing operational efficiency. Furthermore, generative AI serves as a powerful educational tool for the workforce, acting as a mentor by providing instant access to relevant data and insights. This continuous learning and knowledge sharing contribute to a more informed and capable workforce. By enhancing customer centricity and streamlining business-side efficiencies, generative AI plays a crucial role in driving the transformative power of AI in the A&D industry.

Trends and Overarching Consensus

The aerospace and defense (A&D) manufacturing industry is experiencing a significant transformation through the integration of artificial intelligence (AI) technologies. Both traditional AI and generative AI (GenAI) are revolutionizing various aspects of A&D manufacturing by enhancing operational efficiency, quality, and customer-centric processes. The synergy between AI systems and GenAI, supported by extensive data, is delivering tangible results. These advancements notably improve precision, predictive maintenance, supply chain optimization, and sales processes, contributing to the industry’s overall transformation.

As AI technologies become more embedded in A&D manufacturing, they transform the industry’s functioning. AI’s capability to analyze vast data and identify patterns is crucial to this change. In manufacturing, AI drives operational improvements by offering insights that enhance planning and forecasting accuracy. The incorporation of AI-enabled predictive maintenance increases capacity utilization and reduces downtime, improving efficiency. Additionally, quality management benefits from AI-based visual inspections and GenAI, ensuring flaws missed by humans are detected. This AI integration elevates product quality and speeds up design changes and corrective actions.