The intense public and political focus on electric vehicle sales figures often obscures a far more fundamental battle for America’s industrial future. Recent developments, such as Ford’s decision to idle its BlueOval SK battery facility in Kentucky and the federal government’s move to tighten “Buy America” provisions for EV charging infrastructure, are not merely isolated events in the automotive sector. Instead, they are critical signals revealing a deeper, more systemic challenge. The central conflict is not about the week-to-week demand for consumer EVs but about the urgent need to build a resilient domestic supply chain for critical minerals and rare earth elements. This underlying vulnerability in the nation’s industrial “midstream”—the complex processing and refining stages—poses a significant threat to both national security and long-term economic competitiveness, a threat that persists regardless of which end-market is currently in the spotlight.

Beyond the Headlines: Reinterpreting Market Signals

The announcement that Ford’s BlueOval SK battery plant would temporarily halt operations should not be misconstrued as a sign of a collapsing electric vehicle market. This action is more accurately understood as a strategic reallocation of manufacturing capacity, a sophisticated corporate maneuver in response to evolving demand patterns and powerful policy incentives. Rather than signaling an industry-wide failure, the move underscores the inherent flexibility of advanced battery technology and the broader, more complex dynamics of the ongoing energy transition, which encompasses far more than just the electrification of passenger vehicles. This nuanced perspective reveals a market that is not shrinking but rather shifting its focus toward areas of more immediate and stable growth, demonstrating a level of adaptability that is crucial for long-term success in a rapidly changing industrial landscape.

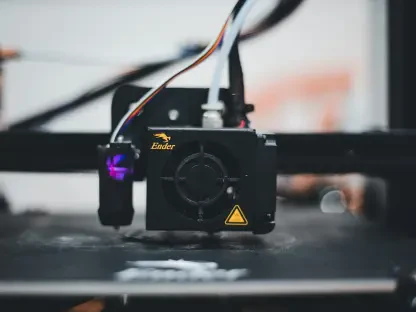

This strategic pivot is underpinned by a compelling market reality: while consumer demand for EVs has proven to be cyclical and highly sensitive to fluctuating policy incentives, the appetite for grid-scale stationary energy storage systems (ESS) is expanding at a remarkable rate. As the nation’s solar energy capacity grows, utilities face an increasing need for massive battery installations to “firm” this intermittent power source, ensuring grid stability and reliability. For a manufacturer like Ford, reallocating its valuable battery production assets from the volatile consumer market to the more predictable and cash-flow-positive ESS segment represents a rational and prudent business decision. It highlights the fact that the core demand for advanced battery components is not disappearing but is being redirected, reinforcing the importance of a resilient supply chain that can serve multiple, equally critical end-markets.

The “Buy America” DilemmA Policy Double-Edged Sword

In parallel with these market shifts, the U.S. Department of Transportation has moved to strengthen domestic-content requirements for any EV charging infrastructure receiving federal funding. The strategic logic behind this policy is undeniably sound, aiming to reduce the nation’s dependence on potentially adversarial foreign supply chains, ensure that taxpayer investments support domestic job creation, and leverage the immense purchasing power of the government to catalyze the growth of American manufacturing. These objectives are foundational to the broader goal of rebuilding a robust industrial base, securing critical economic sectors, and enhancing national security for decades to come. By encouraging the onshoring of production, the policy seeks to create a virtuous cycle of domestic investment, innovation, and employment.

However, this well-intentioned policy carries a significant implementation risk that stems from a potential mismatch between its ambitious mandates and the current reality of domestic industrial capacity. The ecosystem for EV chargers is incredibly complex, relying on a deeply integrated global supply chain for essential components such as advanced power electronics, semiconductors, and specialized metals. Imposing near-total domestic-content requirements before the necessary upstream and midstream segments of that supply chain are sufficiently developed creates a critical sequencing problem. If regulatory mandates outpace the growth of manufacturing capabilities, the most likely outcome is a significant delay in the deployment of the very infrastructure the policy is designed to support. This turns deployment timelines into an unintended “pressure valve,” ultimately undermining the policy’s own strategic goals.

The Real Front Line: America’s Midstream Bottleneck

The true industrial conflict that connects these disparate market and policy events is being waged in the “midstream” of the critical mineral supply chain. This industrial stack can be conceptually divided into three distinct stages: upstream extraction of raw materials such as lithium, graphite, cobalt, and nickel; the crucial midstream stage where these raw materials undergo complex refining and processing to become advanced materials like cathode and anode precursors; and the final downstream assembly of components into finished products like battery packs and electric motors. America’s most profound and dangerous vulnerability lies squarely in this midstream, where the nation is heavily dependent on foreign, and often adversarial, entities for the sophisticated processing capabilities that add the most value and confer the most strategic leverage.

This midstream bottleneck is not an issue confined to the automotive industry; its impact is end-market independent. A temporary slowdown in consumer EV sales does nothing to alleviate the intense pressure on this fragile segment of the supply chain. The strategic pivot by manufacturers toward stationary energy storage, for example, maintains a powerful demand for the exact same processed graphite anodes, refined lithium, and cathode precursor materials required for vehicle batteries. The demand simply shifts from one end market (consumer vehicles) to another (the electrical grid), leaving the core midstream vulnerability as the constant, unresolved challenge. This structural weakness affects every sector reliant on advanced materials, from defense to renewable energy, making it a central issue of national economic policy.

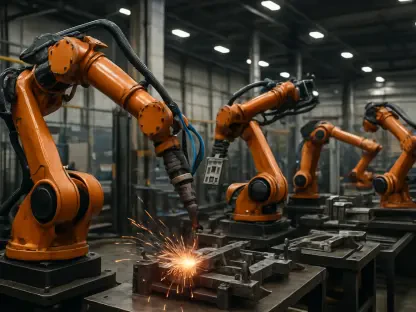

A Persistent Choke Point: The Strategic Case for Rare Earths

Nowhere is this midstream weakness more glaring or strategically perilous than in the supply chain for rare earth elements (REEs). The high-strength permanent magnets derived from REEs like neodymium, praseodymium, dysprosium, and terbium are indispensable for far more than just the motors in electric vehicles. These advanced components are critical enablers for a vast array of modern technologies, including the massive generators in wind turbines, high-efficiency industrial motors that power manufacturing, advanced robotics, unmanned aerial drones, and a wide variety of mission-critical aerospace and defense systems. The ubiquity of these magnets across strategic sectors means that securing their supply is a matter of paramount importance for both economic prosperity and national security.

Due to these diverse and vital applications, the strategic necessity of a secure and resilient REE supply chain remains acute, irrespective of any short-term volatility in consumer markets. Even if the EV market were to experience a prolonged period of stagnation, the baseline demand from the defense, industrial, and renewable energy sectors would be more than sufficient to keep this supply chain under immense pressure. The fundamental structural problem is that the global capacity for the complex processes of REE separation, metallization, and magnet manufacturing is overwhelmingly concentrated outside of the United States and its allies. This geographic concentration creates a persistent strategic choke point, granting outsized geopolitical leverage to a small number of nations and directly impacting America’s ability to control its technological destiny.

The Path to Industrial Resilience

The effort to navigate this new industrial era revealed a delicate balancing act that required careful calibration. Tightening domestic-content rules too quickly before domestic capacity could be built risked stalling the deployment of essential infrastructure. Yet, failing to tighten those rules meant that federal investment would continue to flow overseas, deepening the nation’s long-term supply chain dependencies. The only viable path forward proved to be a meticulously sequenced strategy that paired escalating domestic-content mandates with concrete, fully funded plans to build out the nation’s missing midstream capabilities. Ultimately, the companies and nations that successfully mastered the complex industrial processes of refining, separating, and manufacturing advanced materials at scale within secure jurisdictions were the ones that built true and lasting industrial power.