What if the key to faster, lighter, and more sustainable air travel was already taking shape in a Connecticut facility, where massive jet engine components are crafted with precision, slashing material waste by over 70% and redefining industry standards? Picture a production line at GKN Aerospace, a global leader in the field, making this a reality right now in Newington, Connecticut, with a groundbreaking approach to manufacturing that could transform how the world flies.

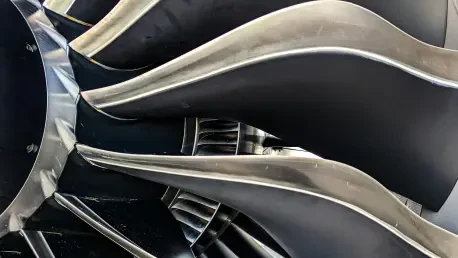

This story isn’t just about a single company’s achievement; it’s about a seismic shift in aerospace manufacturing. The focus is on the Fan Case Mount Ring (FCMR), a critical piece of Pratt & Whitney’s Geared Turbofan engine, powering aircraft like the Airbus A220. Through additive manufacturing (AM), GKN Aerospace has not only earned Federal Aviation Administration (FAA) certification for the largest flight-critical AM component but also set a new benchmark for efficiency and sustainability in an industry hungry for innovation.

A New Era of Aerospace Manufacturing Takes Flight

In the heart of Connecticut, GKN Aerospace’s Newington facility hums with cutting-edge technology. The company has expanded its operations with a dedicated production line for the FCMR, marking a significant milestone in the adoption of additive manufacturing. This isn’t merely an upgrade; it’s a bold reimagining of how complex engine parts can be produced at scale, meeting the demands of a rapidly evolving sector.

The significance of this development lies in its timing. With air travel demand soaring and environmental pressures mounting, the aerospace industry faces an urgent need for solutions that balance performance with sustainability. GKN Aerospace’s investment in AM technology positions it at the forefront of this transformation, offering a glimpse into a future where efficiency and innovation go hand in hand.

Why Additive Manufacturing Is a Game-Changer

Additive manufacturing, often referred to as 3D printing, is no longer a niche concept in aerospace. It addresses long-standing challenges like excessive material waste and lengthy production timelines that plague traditional methods. GKN Aerospace’s adoption of AM for the FCMR slashes material use by a staggering 70%, while also shortening lead times, ensuring that critical components reach assembly lines faster.

Beyond efficiency, this technology strengthens supply chain resilience. In an industry vulnerable to disruptions, AM provides an alternative production method that minimizes delays and maintains consistency. This approach is proving vital for partners like Pratt & Whitney, who rely on timely delivery to keep aircraft production on track.

The broader impact is clear: AM isn’t just a tool; it’s a strategic advantage. By reducing waste and enhancing predictability, GKN Aerospace is helping to lower the environmental footprint of jet engine production, aligning with global sustainability goals while meeting commercial demands.

Breaking Barriers with the Fan Case Mount Ring

At the core of this revolution is the Fan Case Mount Ring, a pivotal component in modern turbofan engines. GKN Aerospace has achieved a historic feat by securing FAA certification for the largest flight-critical part made through additive manufacturing. This accomplishment validates the technology’s readiness for high-stakes applications, setting a precedent for the entire industry.

The Newington facility now plays a central role in this program. Having transitioned key production stages from Sweden to the U.S., the site is fully operational, producing over 30 units per month with plans to scale further. This consolidation boosts capacity and streamlines operations, ensuring that GKN Aerospace can meet growing demand from major clients.

Local impact is equally significant. The expansion has created jobs and deepened the company’s roots in Connecticut, where over 450 employees across two facilities contribute to its success. Supported by state and local partnerships, this growth underscores the region’s status as a hub for aerospace innovation.

Industry Leaders Weigh In on the Breakthrough

The ripple effects of GKN Aerospace’s work are resonating across the sector. A representative from the Connecticut Department of Economic and Community Development hailed the expansion as “a powerful endorsement of the state’s aerospace ecosystem,” citing the skilled workforce and robust infrastructure that enable such advancements. This recognition highlights how regional strengths fuel global innovation.

Collaboration has been key to this success. GKN Aerospace’s long-standing partnership with Pratt & Whitney demonstrates the trust placed in AM processes, with tangible outcomes like reduced material costs and faster production cycles. Industry experts note that these benefits are already influencing real-world applications, encouraging wider adoption of the technology.

Such validation isn’t merely symbolic. It signals to other manufacturers that AM is a viable, proven method for critical components, potentially accelerating its integration into mainstream production. The momentum generated by this project could inspire a wave of similar initiatives, reshaping manufacturing practices on a global scale.

Lessons from GKN Aerospace for the Industry

For aerospace stakeholders eager to stay competitive, GKN Aerospace’s journey offers valuable insights. First, embracing additive manufacturing can dramatically improve efficiency—evidenced by the FCMR’s material savings and reduced lead times. Companies should explore AM for complex parts to gain similar advantages in their operations.

Second, strategic alliances matter. Partnering with local governments and industry leaders, as GKN Aerospace did with Connecticut authorities and Pratt & Whitney, provides access to critical resources and expertise. These collaborations can amplify the impact of technological investments.

Finally, navigating regulatory landscapes is essential. Securing certifications like the FAA approval for the FCMR ensures that innovations meet safety and commercial standards. By prioritizing compliance and building resilient supply chains through AM, businesses can mitigate risks and deliver consistent results to clients.

Reflecting on a Transformative Milestone

Looking back, GKN Aerospace’s expansion in Connecticut stood as a defining moment for aerospace manufacturing. The dedication to additive manufacturing for the Fan Case Mount Ring showcased how innovation could tackle pressing industry challenges, from material waste to supply chain vulnerabilities. This initiative not only elevated production standards but also cemented the company’s role as a pioneer in the field.

The broader implications were profound, inspiring other manufacturers to explore similar technologies. For the future, the focus should shift to scaling these advancements, investing in workforce training, and fostering partnerships to drive wider adoption of sustainable practices. The path forward lies in building on this foundation, ensuring that the aerospace sector continues to soar with efficiency and environmental responsibility at its core.