Stellantis and CATL have embarked on an ambitious project to establish a large-scale lithium iron phosphate (LFP) battery plant in Zaragoza, Spain, with a significant investment potentially reaching up to €4.1 billion. This strategic collaboration aims to commence production by the end of 2026 and achieve a remarkable capacity of up to 50 GWh. The success of this venture hinges on receiving support from Spanish and European authorities and observing favorable developments in the electrical market. This project embodies the industry’s drive towards technological advancement, sustainability, and cost reduction in battery electric vehicles (BEVs).

Advancing Battery Technology

Collaboration and Technological Innovation

The collaboration between Stellantis and CATL is poised to make significant strides in battery technology, underscoring the carmaker’s commitment to sustainable automotive solutions. LFP batteries are known for their durability and safety, making them an excellent choice for mass-market electric vehicles. By focusing on enhancing LFP technology, Stellantis aims to provide high-quality, durable, and affordable BEVs. The emphasis is not solely on vehicle performance but also on cost efficiency, enabling wider adoption of electric vehicles.

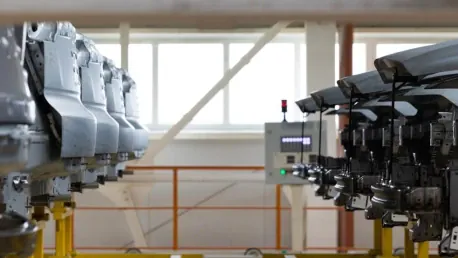

CATL brings extensive expertise in battery manufacturing to the table, leveraging its operational experience with plants in Germany and Hungary. Their cutting-edge technology and advanced manufacturing processes will undoubtedly bolster the production capabilities of the new Zaragoza plant. This venture reflects a broader industry movement towards establishing robust battery value chains that are not only efficient but also environmentally sustainable. By integrating sophisticated battery chemistries such as lithium-ion nickel manganese cobalt (NMC) alongside LFP, Stellantis and CATL are setting new standards in the battery industry.

Targeting the B and C Segments

One of the significant aspects of this joint venture is its target market. Stellantis plans to focus on the B and C segments, which include passenger cars, crossovers, and SUVs equipped with intermediate ranges. LFP batteries are particularly suitable for these vehicle segments due to their balance of cost, performance, and safety. The goal is to produce electric vehicles that are not only environmentally friendly but also accessible to a broader range of consumers.

By offering affordable BEVs in the B and C segments, Stellantis aims to drive significant market penetration and encourage more consumers to transition to electric vehicles. This initiative aligns with Stellantis’ Dare Forward 2030 strategic plan, which includes a strong focus on sustainability and decarbonization. The collaboration with CATL enhances Stellantis’ ability to meet these strategic goals by providing a reliable supply of high-quality batteries designed to meet the demands of the European market.

Supporting Climate Goals

Stellantis’ Strategic Plan

Stellantis’ Dare Forward 2030 strategic plan outlines an ambitious roadmap towards sustainability and decarbonization. As part of this strategy, the company aims to achieve carbon net zero by 2038. The joint venture with CATL is a critical component of this plan, as it ensures a stable supply of LFP batteries necessary for producing affordable BEVs. By focusing on sustainable battery technology, Stellantis is taking concrete steps towards reducing its carbon footprint and promoting environmental stewardship.

The dual-chemistry approach adopted by Stellantis caters to a diverse customer base, exploring innovative battery technologies that can meet varying needs. This flexibility allows the company to remain competitive in an evolving market while staying committed to its sustainability goals. By strengthening its battery supply chain and investing in advanced technologies, Stellantis is well-positioned to lead the charge towards a more sustainable automotive industry.

CATL’s Commitment to Zero-Carbon Technology

CATL’s commitment to global zero-carbon technology complements Stellantis’ sustainability objectives. The company’s expertise in battery manufacturing and dedication to environmental responsibility make it an ideal partner for this venture. CATL’s operational plants in Germany and Hungary have already set high standards for efficiency and sustainability, which will be replicated in the new Zaragoza plant.

The collaboration with Stellantis underscores CATL’s broader goal of supporting e-mobility and energy transition efforts both in Europe and globally. By combining technological innovation with a strong focus on sustainability, CATL is playing a pivotal role in shaping the future of the automotive industry. The joint venture with Stellantis is expected to create significant advancements in battery technology, contributing to the decarbonization efforts of both companies.

Driving Down BEV Costs

Affordability and Market Penetration

One of the primary objectives of the Stellantis and CATL joint venture is to drive down the cost of BEVs, making them more accessible to a wider audience. The production of high-quality LFP batteries at scale will significantly reduce costs, enabling Stellantis to offer affordable BEVs in the European market. This affordability is crucial for increasing market penetration and encouraging more consumers to transition to electric vehicles.

The focus on the B and C segments, which include high-demand vehicle categories like passenger cars, crossovers, and SUVs, further enhances the potential for widespread adoption of BEVs. By addressing the affordability barrier, Stellantis and CATL are paving the way for a more sustainable and inclusive automotive market. This initiative aligns with broader industry trends towards decarbonization and the adoption of electric vehicles.

Long-Term Impact on the Industry

Stellantis and CATL have joined forces for an ambitious project to create a large-scale lithium iron phosphate (LFP) battery plant in Zaragoza, Spain. The investment for this endeavor could potentially reach up to €4.1 billion. They aim to start production by the end of 2026, targeting a substantial capacity of up to 50 GWh. This collaboration seeks support from Spanish and European authorities and relies on favorable developments in the electrical market to succeed.

This venture signifies the industry’s dedication to technological progress, sustainability, and reducing costs in battery electric vehicles (BEVs). The strategic location in Spain positions the project to leverage regional expertise, infrastructure, and market access. By focusing on LFP technology, Stellantis and CATL aim to advance battery performance while maintaining a cost-effective and sustainable approach. This project is not just about production capacity; it represents a significant step towards the future of green transportation and the reduction of carbon footprints in the automotive industry.