An Introduction to India’s Unique EV Ambition

As the global automotive industry accelerates toward an electric future, India is not merely following the trend—it is consciously charting its own course. Rejecting a one-size-fits-all approach of importing global vehicle models, the nation is building its electric vehicle (EV) manufacturing strategy on a foundation of indigenous innovation, deep localization, and digital prowess. This article explores the strategic imperatives shaping India’s journey, revealing how a blend of “frugal engineering” and consumer-centric design is poised to create a resilient and globally competitive EV ecosystem. It will delve into the core pillars driving this transformation, from the critical need for market-specific products to the role of digital tools in taming manufacturing complexity, ultimately illustrating a unique playbook designed for India’s distinct challenges and opportunities.

From Policy Kickstarts to an Innovation-Led Ecosystem

India’s electric vehicle journey began with critical government interventions that laid the essential groundwork for the industry. Policies such as the Faster Adoption and Manufacturing of (Hybrid &) Electric Vehicles (FAME) scheme and the Production Linked Incentive (PLI) initiative were instrumental in seeding the initial ecosystem, encouraging investment, and spurring early consumer adoption. However, it quickly became apparent that simply incentivizing the assembly of foreign-designed kits would not be a sustainable long-term strategy. The country’s diverse and demanding operating conditions—from extreme climate variations to challenging road infrastructure—exposed the limitations of global models. This realization marked a pivotal shift in strategy from policy-driven adoption to an industry-led focus on deep-rooted, indigenous innovation capable of addressing the market’s specific needs for affordability, durability, and reliability.

The Pillars of India’s Indigenous EV Blueprint

From Global Templates to Local Relevance The Primacy of Customization

The cornerstone of India’s emerging EV strategy is an unwavering focus on “local relevance.” Industry leaders unanimously agree that success hinges on designing products from the ground up to meet the specific demands of the Indian consumer. For the value-conscious Indian market, the total cost of ownership (TCO)—encompassing maintenance, energy efficiency, and durability—trumps the initial purchase price. This necessitates a deep dive into product customization and robust engineering that can withstand India’s unique usage patterns. Furthermore, this principle is even more critical in the commercial vehicle sector, where a three-wheeler’s operational demands in Uttar Pradesh are vastly different from those in Southern India. A consumer-centric approach that accounts for regional variations in load, terrain, and daily usage is therefore not just a competitive advantage but a fundamental requirement for market acceptance.

Digitalization as the Force Multiplier Taming Complexity and Accelerating Innovation

As Indian manufacturers scale up, they face an exponential rise in operational complexity. Digital transformation has emerged as the central enabler for navigating this challenge. Advanced digital tools, including AI-led modeling, comprehensive virtual validation, and advanced simulation, are becoming indispensable for deconstructing complexity into manageable processes. These technologies allow engineers to test and refine thousands of design iterations in a virtual environment, drastically reducing development timelines and the need for expensive physical prototypes. By embedding generative design and real-time simulation capabilities directly into the workflow, companies can create lighter, stronger, and more cost-efficient vehicle components, directly enhancing both performance and affordability in a highly competitive market.

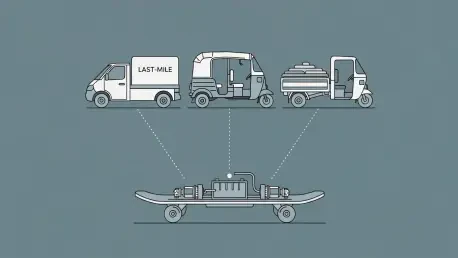

Achieving Scale Through Strategy The Role of Modular Platforms and a Maturing Ecosystem

To reconcile the need for customization with the economic imperative of scale, manufacturers are increasingly adopting modular platform strategies. These flexible architectures can be adapted across a wide range of vehicle types, from last-mile delivery vans to specialized agricultural vehicles, using a common set of underlying components. This approach enables significant economies of scale, driving down costs and making EVs accessible to a broader audience. As local production volumes grow, this strategy is also fueling the development of a more sophisticated domestic component ecosystem. For example, the quiet nature of an EV powertrain means other parts, like air compressors, must be re-engineered to be quieter. This demand for new, EV-specific components is driving deeper localization and strengthening the entire domestic supply chain.

The Road Ahead Emerging Trends and Future Trajectories

Looking forward, India’s EV industry is set to evolve rapidly. The current focus on vehicle-level localization will deepen, with a strategic push toward mastering the production of high-value components like battery cells and semiconductors—a persistent gap in the current ecosystem. As the hardware matures, software and connected-vehicle technologies will become the next frontier for innovation and a key differentiator for Indian brands. Furthermore, by perfecting the art of creating durable, affordable, and context-aware EVs, India is uniquely positioned to become a major export hub, not for Western markets, but for other emerging economies across Asia, Africa, and Latin America that share similar operating conditions and consumer priorities.

Key Takeaways and Strategic Imperatives

The analysis of India’s EV manufacturing strategy reveals a clear and cohesive vision built on self-reliance. The primary takeaway is that the nation’s success will not come from imitation but from a synergistic combination of frugal engineering, a digital-first design philosophy, and the strategic use of modular platforms. For businesses, this translates into clear imperatives: OEMs must prioritize deep consumer research and invest in flexible R&D; component suppliers must anticipate the shift to specialized EV parts; and policymakers must continue to foster a collaborative ecosystem that closes critical gaps in the high-value supply chain. For consumers, this homegrown approach promises a future of more affordable, reliable, and purpose-built electric vehicles.

A Self-Reliant Drive into the Future

Ultimately, India is forging its own path in the global EV revolution by writing its own playbook. The country’s transition is being defined not by the adoption of global technologies but by a strategic reinvention led by indigenous innovation. The fusion of a cost-conscious engineering mindset with cutting-edge digital tools represents India’s unique competitive advantage. By remaining focused on creating products authentically tailored to its own context, the nation is not only building a sustainable domestic industry but is also positioning itself to become a formidable global leader in providing relevant and accessible electric mobility solutions for the world.