The aviation industry’s pursuit of a sustainable future has long been tethered to the promise of batteries, yet this path introduces a fundamental paradox of adding immense weight to an aircraft in the name of efficiency. A recent technological breakthrough, however, suggests a radically different approach might be on the horizon, one that bypasses the energy storage dilemma altogether. This development challenges the prevailing assumption that electrification in the skies must rely on heavy, range-limiting batteries, opening a new frontier for hybrid-electric propulsion.

A New Vision for Green Aviation Without Batteries

The prevailing narrative surrounding green aviation has centered on hybrid systems that depend on large, heavy battery packs to supplement traditional jet engines. This model, while promising in theory, has consistently run into the immovable wall of physics, where the energy density of batteries pales in comparison to that of jet fuel. Consequently, the industry has faced a trade-off between reducing emissions and maintaining the range and payload capacity essential for commercial flight.

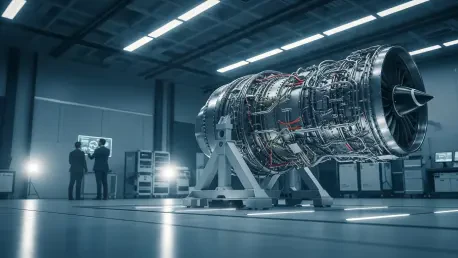

In a direct challenge to this paradigm, engineers at GE Aerospace have successfully demonstrated a hybrid-electric system capable of operating entirely without on-board energy storage. Instead of carrying power, this system generates it as needed directly from the engine’s mechanics. This innovative architecture reimagines the jet engine not just as a source of thrust, but as a self-contained, highly efficient power plant that can intelligently manage its own energy to reduce fuel consumption.

The Weight of Progress in Electric Aviation

The primary obstacle for electric and hybrid-electric aviation remains the profound weight of batteries. To power a commercial airliner, a battery pack would need to be astronomically heavy, severely limiting the aircraft’s range and its capacity for passengers and cargo. This issue of energy density—the amount of energy stored per unit of weight—is the central reason why all-electric long-haul flight remains a distant prospect.

This challenge creates significant design and operational complexities. Beyond the initial weight penalty, batteries introduce thermal management issues and require extensive structural modifications to aircraft. By eliminating the need for an external energy storage system, the new hybrid-electric concept sidesteps these hurdles, allowing for a more streamlined integration of electric components that enhances, rather than compromises, the aircraft’s fundamental performance.

How a Battery-Free Hybrid Engine Redesigns Flight

The core of this groundbreaking technology lies in the deep integration of electric motor/generators within a high-bypass turbofan engine. These compact yet powerful components are embedded directly into the engine’s architecture, allowing them to perform dual functions. They can extract electrical power from the engine’s rotational energy during efficient cruising phases and then act as motors to inject that same power back into the system when extra thrust is needed, such as during takeoff and climb.

This dynamic energy transfer enables a more optimized and efficient engine operation across all phases of flight. The system intelligently balances mechanical and electrical power to keep the gas turbine running at its peak performance level, which significantly reduces fuel burn and CO2 emissions. This creates a closed-loop system where power is harvested and redeployed on demand, marking a departure from the static model of simply drawing from a stored energy source.

Exceeding Expectations with NASA Validation

The viability of this battery-free architecture was proven during extensive ground tests completed in 2025. Conducted as part of NASA’s Turbofan Engine Power Extraction Demonstration project, the system was subjected to rigorous trials simulating real-world flight conditions. The results were definitive, with the technology surpassing all of NASA’s ambitious performance goals, which were established to meet industry requirements for substantial fuel efficiency gains.

This successful demonstration represented more than just a proof of concept for individual components. It validated the entire integrated system, including the complex control software required to manage the seamless flow of power within the engine. By proving that a megawatt-class hybrid system could perform reliably and efficiently as a cohesive unit, the tests marked a critical step in de-risking the technology for future aircraft development.

The Path Forward with the RISE Program

This milestone is a cornerstone of the broader CFM International RISE (Revolutionary Innovation for Sustainable Engines) program. Co-led by GE Aerospace and Safran Aircraft Engines, the RISE program aims to develop a suite of technologies capable of achieving a more than 20% improvement in fuel efficiency and emissions compared to the most advanced engines currently in service. The battery-free hybrid-electric system is a key enabler of this ambitious goal.

Looking ahead, the validated hybrid-electric technology will be integrated with other advanced concepts from the RISE program, including an Open Fan architecture and a compact engine core. The next phase involves further ground and flight tests scheduled for later this decade, which will bring this new generation of propulsion systems one step closer to the tarmac. This methodical approach ensures that each innovation is thoroughly tested before being combined into a new engine designed to redefine air travel. The successful demonstration of a battery-free system established a new and potentially more practical path toward achieving aviation’s sustainability targets. It shifted the engineering focus from energy storage to in-flight energy management, a conclusion that opened up new design possibilities for the next generation of commercial aircraft. This achievement underscored that the future of greener skies may depend not on carrying more power, but on using it more intelligently.