A high-stakes opening

In India’s race to scale semiconductors, gigafactories, and high-spec pharma, the silent variable deciding yield, downtime, and safety was the air moving above tools and across electrodes before anyone noticed. The cleanroom used to be a background utility; now it sits on the critical path, where a stray micron can scrap a wafer lot or destabilize a coating line and a pressure drift can trigger costly rework.

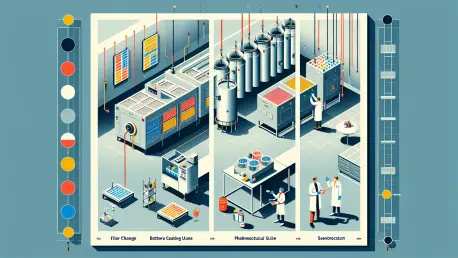

This shift has pushed filtration from a static expense to a strategic lever. The latest move came as Freudenberg Filtration Technologies expanded its India portfolio with next-generation fan filter units, integrated Bag-In/Bag-Out systems, and NMP-resistant filters. Each addresses a different bottleneck—airflow uniformity, contained maintenance, and solvent compatibility—yet together they point to a cleaner, safer, and more connected manufacturing baseline.

Why this matters now

Tight specs define the new manufacturing floor. Advanced fabs and battery lines increasingly target ISO 14644-1 Class 5–7 zones, with ULPA filtration in critical bays and dry rooms. In electrode manufacturing, VOCs, acid gases, and aggressive solvents strain conventional media; N-Methyl-2-Pyrrolidone (NMP), in particular, tests mechanical integrity under high humidity and chemical load.

Compliance pressures are rising in parallel. EHS teams face twin mandates: prevent operator exposure to toxic or biological agents and contain emissions during routine maintenance. In battery production, NMP handling is scrutinized by regulators for worker health and air quality, and poor capture increases both risk and rework. An incident-free ramp depends as much on filtration architecture as it does on equipment choice.

Energy is the other lever that refuses to stay quiet. Cleanrooms can consume 30–50% of a facility’s total energy, and fan energy scales with pressure drop and control strategy. Operators now track kWh per square foot and audit trails with the same rigor as yields. Digital monitoring, once a nice-to-have, has become the backbone for uptime, alarms, and validation at scale—especially across multi-plant networks where consistency can make or break margins.

Inside the tech reshaping cleanrooms and dry rooms

Smart fan filter units are the frontline. Freudenberg’s latest FFUs pair HEPA and ULPA media with low-vibration frames to protect sensitive lithography, coating, and assembly steps. EC motors cut energy by up to 35% while enabling tighter airflow control, translating into more uniform laminar flow and fewer process excursions. “The stability at the tool face is night and day when vibration and velocity are uniform,” a cleanroom manager said.

Connectivity adds the missing layer of foresight. Cluster control via CCM software, differential pressure sensing, and filter-life analytics let facilities balance energy and protection in real time. Teams can correlate yield hits with airflow anomalies, or flag pressure drift before it becomes particulate ingress. One commissioning team reported shaving days off validation by exporting continuous logs for auditors rather than staging repeated manual tests.

Safety upgrades are equally visible. Integrated Bag-In/Bag-Out systems bring gas-tight seals and pressure-tested housings that contain hazardous load during filter changeouts. “BIBO reduced our exposure risk during maintenance and gave EHS a defensible protocol,” an EHS lead noted. Stainless-steel modular builds accept HEPA/ULPA, activated carbon, and chemical filters, making the same platform viable for pharma suites, specialty chemicals, and solvent-heavy battery areas.

Voices from the floor and the numbers behind them

Battery engineers keep a close eye on NMP, and filter failure under solvent stress is a known headache. NMP-resistant filters engineered for high humidity and organic solvent exposure maintain particle retention and airflow stability in dry rooms, electrode coating lines, and solvent recovery loops. “Compatibility with NMP is the difference between planned maintenance and a mid-shift shutdown,” a process engineer said.

Standards give a clear yardstick. ISO 14644-1 spells out particle limits for Class 5–8 cleanrooms, and dry rooms layer humidity control on top. HVAC and filtration can account for a sizable share of energy in such facilities, and incremental pressure reductions translate into meaningful kWh savings. Meanwhile, regulatory views on NMP and VOCs are sharpening, with guidance pushing for capture, recovery, and verified containment during maintenance.

The early anecdotes are pragmatic rather than flashy. Sites using digital monitoring report fewer tool excursions tied to undetected airflow changes, and some avoided rework by responding to pressure alerts before contamination could spread. Quantifiable gains typically appear as bands, not absolutes: energy savings in the teens to mid-30% with EC motors and smarter setpoints, longer filter service intervals through condition-based changes, and improved uptime as changeouts move from emergency to scheduled windows.

A practical roadmap for decision-makers

The playbook starts with risk zoning. Map areas by particle sensitivity, solvent exposure, and chemical or biological risk, then align each zone to target ISO classes and media types. In high-density ceilings, specify EC-motor FFUs and validate both vibration and airflow uniformity at the tool face. Enable cluster control, differential pressure sensing, and life tracking from day one; retrofitting data later costs more and proves harder to standardize.

Engineer maintenance out of the blast radius. Where toxic powders, aggressive solvents, or biohazards live, deploy BIBO with gas-tight seals and pressure testing as a standard, not an exception. For dry rooms and coating lines, choose NMP-resistant filters and design for high humidity without media degradation. Tie filtration to KPIs: track kWh per FFU, pressure drop trends, and change intervals, and feed alerts into MES or BMS for predictive maintenance and clean audit trails.

Scale is the endgame. Modular, standards-compliant SKUs let operators clone successful lines across sites, while predefined validation protocols compress ramp-up. Build ROI models that include avoided scrap, energy savings, reduced downtime, and safety compliance, alongside the higher upfront cost of solvent-compatible media. In a market sprinting to gigafactory volumes, the cheapest filter is often the costliest choice once yield, uptime, and regulatory risk are fully priced.

The bottom line

Smart filtration had shifted from background utility to performance catalyst, with clean air defining the ceiling on yield, safety, and energy efficiency in India’s most advanced plants. Practitioners found that EC-motor FFUs, BIBO containment, and NMP-ready media, stitched together with real-time monitoring, delivered steadier tools, safer maintenance, and clearer audits. The next moves lay in disciplined zoning, solvent-proof designs, and data-led operations that scaled consistently across sites, turning air from a hidden liability into a measurable advantage.