The familiar tug of a mechanical handbrake lever is rapidly vanishing from modern vehicle interiors, replaced by a discreet button that signals the profound technological transformation occurring beneath the surface. This subtle shift from mechanical force to electronic control is more than a convenience; it represents a fundamental rewiring of automotive architecture. It is precisely this evolution that German automotive technology giant ZF Group is championing in India with the inauguration of its state-of-the-art production line for electric park brake (EPB) systems at its Oragadam plant near Chennai, a move that firmly positions the nation at the forefront of advanced vehicle manufacturing. This development is not merely an expansion of production capacity but a strategic investment in India’s future as a global hub for sophisticated, software-defined automotive components.

How Does a Parking Brake Signal a Revolution in India’s Automotive Future?

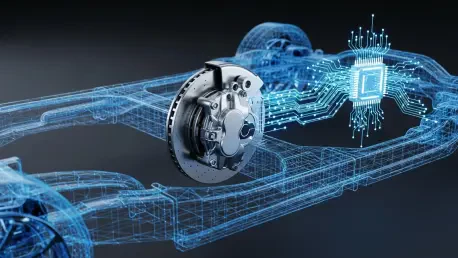

At its core, the electric park brake system replaces the traditional network of cables and levers with a compact, electronically controlled unit integrated directly into the brake caliper. This technological leap provides a multitude of advantages over its mechanical predecessor. By eliminating the physical handbrake or foot pedal, automakers gain significant interior design flexibility, allowing for more spacious and ergonomic cabin layouts. Moreover, the electronic actuation is quieter, more efficient, and offers a level of precision that mechanical systems cannot match, enhancing both performance and user experience.

The launch of ZF’s EPB line in India signifies a crucial step in the nation’s automotive maturation. It marks the local manufacturing of a component that is essential for the next generation of vehicles, particularly electric vehicles (EVs) and software-defined vehicles (SDVs). The domestic availability of such advanced technology enables Indian original equipment manufacturers (OEMs) to integrate sophisticated features into their models more cost-effectively, accelerating the adoption of smarter and safer vehicles across the passenger and light commercial segments. This localization effort is pivotal, transforming India from a consumer of advanced technology into a key producer.

The Global Shift to Smarter, Safer Vehicles

The transition to EPB systems is a microcosm of a much larger industry-wide trend: the move from purely mechanical components to intelligent, software-enabled systems. Modern vehicles are increasingly becoming computers on wheels, where electronic control units (ECUs) manage everything from engine performance to safety features. Braking systems, once a bastion of mechanical engineering, are now at the center of this revolution. The ability to control braking electronically opens the door to a host of integrated functionalities that are impossible with conventional hardware.

This evolution is fundamentally about enhancing vehicle safety and driver assistance. An EPB system is a critical enabler for advanced driver-assistance systems (ADAS), facilitating features like automatic emergency braking and intelligent brake pad wear sensing, which proactively alert drivers to maintenance needs. Furthermore, its dynamic actuation capabilities are integral to functions like automatic hill hold and controlled braking maneuvers. ZF’s extensive global experience, underscored by the deployment of over 250 million EPB calipers worldwide, brings a wealth of proven expertise and reliability to its Indian operations, ensuring that locally produced systems meet the highest international safety standards.

Decoding ZF’s Strategic Play in the Indian Market

The inauguration of the Oragadam facility is a clear execution of ZF’s robust “Make in India for India and the World” strategy. This dual-pronged approach is designed to cater directly to the burgeoning domestic demand from Indian automakers while simultaneously establishing the plant as a critical export hub within ZF’s global supply network. By localizing the production of high-tech components, ZF not only strengthens its competitive position in the Indian market but also leverages the country’s manufacturing prowess to serve its international clientele.

A cornerstone of this strategy is the meticulous development of a local supply chain ecosystem. ZF has been instrumental in cultivating a network of Indian suppliers capable of producing the intricate mechanical and electronic components required for its EPB systems. This commitment to localization goes beyond mere assembly; it involves building a resilient and cost-effective manufacturing foundation that reduces dependency on imports and insulates operations from global supply chain volatility. While specific investment figures remain undisclosed, the extensive effort to build a local supplier base indicates a significant and long-term commitment to the Indian automotive industry.

Voices from the Forefront of Automotive Innovation

The strategic importance of this milestone was articulated by key leaders within the organization. Akash Passey, President of ZF Group India, emphasized that the launch represents a new chapter of growth, perfectly aligning with the company’s comprehensive localization agenda. He framed the initiative as a tangible demonstration of confidence in India’s capacity to merge sophisticated engineering with world-class manufacturing, thereby serving a diverse and demanding global customer base from a single, integrated hub.

Providing a global technology perspective, Peter Holdmann, a member of ZF’s Board of Management and Head of Chassis Solutions, highlighted the fundamental shift in vehicle architecture. He explained that braking systems are rapidly evolving from mechanical assemblies into complex, software-driven safety technologies. This transition is central to the development of EVs and SDVs, where seamless electronic integration is paramount. His insights underscore that the EPB is not just a component but a critical node in the increasingly complex and intelligent network that defines the modern automobile.

The Tangible Impact: What ZF’s Expansion Means for the Industry

The immediate effect of this expansion is substantial, with the new production line boasting an annual capacity of 800,000 units. This output is already being channeled to Indian OEMs, with the EPB systems being integrated into the latest electric passenger vehicles launched in the country. This rapid market adoption demonstrates the pressing need for such advanced technologies and validates ZF’s decision to industrialize production locally, moving swiftly from a pilot phase to full-scale manufacturing.

On a broader scale, ZF’s investment sends ripples across the entire Indian automotive ecosystem. It fortifies the domestic supply chain, fosters the development of specialized skills, and elevates India’s standing in the global value chain for advanced automotive components. This initiative is more than a corporate expansion; it is a catalyst for industrial advancement, reinforcing India’s trajectory toward becoming a self-reliant and globally competitive powerhouse in automotive technology and manufacturing. The successful launch of the EPB line did not just build a product; it built confidence, capability, and a clearer path toward the future of mobility in India.