The U.S. manufacturing industry added $2.8 trillion to the GDP in 2023—a slight rise from the year before. A steady increase, but one that shows the industry is holding strong.

As an industry professional, you doubtlessly understand the imperative of strengthening your efforts to meet modern demands.

That’s where Industry 4.0, also called the Fourth Industrial Revolution or 4IR, comes into play—bringing more data, better connectivity, advanced analytics, and human-machine collaboration.

In 2019, 68% of businesses saw Industry 4.0 as a top priority, and 70% were already testing or using new technologies. Compare that to before 2014, when hardly anyone was even searching for the term on Google. The shift is striking.

It’s the next step in the digital transformation of manufacturing, and it’s compelling decision-makers to broaden their investments and harness the power of modern technology.

To help you thrive in the future of manufacturing, we composed this article on critical components to integrate into your operations:

Internet of Things (IoT)

Big data and smart analytics

Artificial Intelligence (AI) and Machine Learning (ML)

Augmented Reality (AR) and Virtual Reality (VR)

Use data, connectivity, analytics, and human-machine collaboration to stay competitive in Industry 4.0. Keep reading to uncover the technologies and solutions that will drive your organization’s excellence in the new world of manufacturing, as well as our preferred solutions for each component.

Innovating Operations for the Future of Industry

These technologies are the backbone of smart factories, keeping businesses competitive.

Augmented and virtual reality are making training and maintenance immersive, while platforms like Splunk, SAP HANA, and AI tools from Google and IBM are driving automation and predictive power. To embrace Industry 4.0, you must lean into big data, AI, and ML to boost efficiency and make smarter decisions.

Create a Connected Factory with IoT

IoT makes production smarter and more agile, pushing automation and improving performance. It allows real-time monitoring, predictive maintenance, and streamlined workflows—all driving efficiency and cutting waste. The right solution will help you keep inventory in sight and streamline logistics, predict breakdowns, keep downtime to a minimum, and cut energy costs.

However, for IoT to turn old manufacturing systems into connected, smart operations, it must leverage:

Cloud platforms: With edge computing, data gets processed on-site, cutting down on delays and avoiding overload.

Sensors: These collect the data that drives everything, while actuators do the heavy lifting, turning information into action. IoT transforms supply chains, too, using RFID tags and GPS trackers to track inventory in real time.

Robust security: Encryption and authentication keep sensitive data safe.

Safety tools: Environmental sensors and wearables monitor the workplace to ensure compliance and protect workers.

Siemens’s IoT Solution

Insights Hub powers smart manufacturing through its IoT offering, delivering the information you need to boost performance and efficiency.

Siemens’ solution empowers you to leverage asset and operational data to transform your efforts, cut costs, and boost product quality across the supply chain.

Start by connecting your assets to the cloud and gathering the right data for continuous improvement. Advanced analytics will reveal insights you couldn’t see before, helping you fine-tune operations and drive better performance.

Unlock the power of IoT to monitor assets, streamline manufacturing, and predict quality issues before they happen.

Start for free and get step-by-step guidance on leveraging Insights Hub.

Bigger Data. Smarter Analytics

Big Data makes production leaner by cutting waste and boosting efficiency. It trims costs by finding inefficiencies and reducing resource use. Coupled with data-driven insights, decisions are sharper and faster.

However, while most manufacturing leaders see the value of Big Data, few have put it into action. A survey by BCG and the World Economic Forum shows only 17% are using data analytics in their operations. The potential is there—it’s just not being fully realized.

Getting big data analytics off the ground in manufacturing isn’t an easy feat. It comes with its fair share of challenges that can hinder progress if you’re not prepared.

Here’s what you’ll need to keep in mind for big data and analytics excellence:

Implementing big data analytics isn’t cheap, especially for small and mid-sized manufacturers. The costs of infrastructure, software, and skilled talent add up fast.

You’ll need a workforce that knows its way around big data, data science, and analysis, which means improving team training or hiring specialists.

The data is often scattered across systems like SCADA and ERP, and you’ve got to pull it all together for the analytics to work.

As data volume grows, security becomes a major challenge, and managing it properly requires careful attention.

Improving Analysis with N-iX

N-iX delivers robust cloud solutions that help you take the load off your on-premise systems, giving you the power to handle massive datasets. With the cloud, you get flexible storage and scalability as your needs grow.

In addition, their smart data science solutions—using AI and ML—keep you ahead with predictive and behavioral analytics.

AI and ML Serve Various Purposes

ABI Research forecasts $4.4 billion in extra revenue from GenAI investments in manufacturing between 2026 and 2029, with a total of $10.5 billion by 2033.

Naturally, manufacturers are turning to Generative AI to speed up root cause analysis, streamline work instructions, and boost coding skills among their teams.

As more manufacturers focus on this technology, it’s set to revolutionize the way they work. Key use cases include:

Autonomous Mobile Robots

Amazon has over 750,000 robots on the floor, with Sequoia leading the charge, speeding up inventory by 75% and cutting order times by 25%.

Manufacturers are catching on, using collaboration robots (cobots) to back up their workers, fix errors, and move faster. Sequoia doesn’t just speed things up—it makes same-day and next-day shipping easier. And with 85% of manufacturers already investing in AI/ML for these machines, the future is all about efficiency.

Improving Documentation

When a machine overheats, AI steps in with clear, step-by-step instructions to fix the problem fast. It saves time, cuts down on errors, and gets things running smoothly.

Workers can ask GenAI—whether by voice or text—what to do, and it delivers the answers right away. AI also takes care of the paperwork, putting together machine lists and standard procedures, so workers always have what they need.

Quality Assurance

Today’s assembly lines are driven by data and run automatically, guided by algorithms to make sure everything works at its best. Quality assurance is what keeps it all steady, making sure every product meets the same high standards. AI, using machine vision, spots defects as soon as they happen. If a product isn’t up to par, the AI raises the alarm, so workers can fix it in real time.

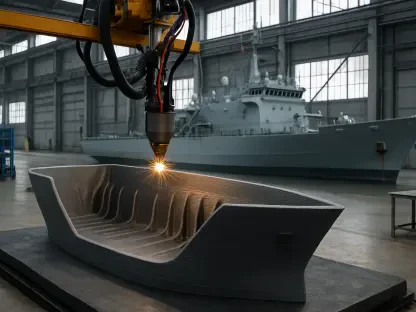

Generative design

Using ML, this use case mimics an engineer’s thought process. Generative design lets manufacturers quickly create thousands of design options, speeding up innovation and fine-tuning performance.

Feed it parameters—materials, dimensions, weight, strength, and cost—and the software explores endless solutions, all while optimizing for what matters most.

IBM Pioneers the Sector

IBM Watsonx stands as a leader in AI, delivering the tools manufacturers need for quality control and product lifecycle management.

Watsonx keeps an eye on equipment health, predicting failures before they happen and cutting downtime. IBM’s solution also spots defects early in production, keeping quality high. By analyzing market trends and customer feedback, Watsonx helps manufacturers make smart choices during product development.

Extend Reality for Everyone

For now, today’s factories still have more people than machines, but the gap is closing fast. AR and VR platforms are ready to change modern manufacturing in ways we’re only starting to see.

Manufacturers can take control and build the future they want. These technologies are pushing the evolution of factories, transforming them into the workplaces of tomorrow.

Mixed reality lets the physical and digital worlds blend together, interacting in real time. AR and VR are part of this broader extended reality (XR) world. AR adds digital content to the real world, while VR takes you into a completely virtual space.

Your forward-thinking peers are leveraging VR and AR to optimize the assembly line, simulating the movement of products and workers to spot collisions or slowdowns and adjust the workflow to prevent them.

AR and VR give them a digital twin of the assembly line, where they can test ideas and catch bottlenecks before making real changes. They can also simulate new layouts to find the best design for boosting performance. It’s all about making things more efficient, saving time and money in the process.

Unity Industry

Unity Industry provides immersive tech that helps you boost worker experience, helping them complete work in interactive, engaging ways. And with these tools, manufacturers can design, test, and refine workflows and products virtually, driving operational excellence in every corner of their business.

In addition, AR/VR simulations let manufacturers prototype and train for real-world scenarios, saving time and improving safety.

Conclusion

IoT, AI, and extended reality are reshaping manufacturing. These modern tools help you transform your operations, make them more resilient, and ensure your processes are future-proof.

Choose the right tools, and your business will thrive in this new age of industrial innovation. IoT, big data, AI, and extended reality each have their role to play. Pick carefully, and you’ll see the benefits everywhere—faster processes, less downtime, and higher productivity across the board.

Now is the time for manufacturers to take the lead and stay ahead of the curve.