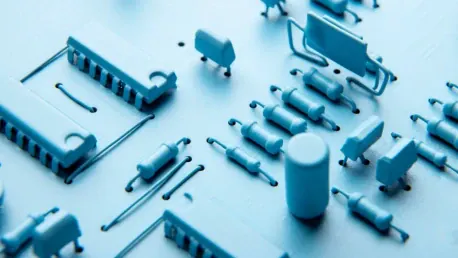

In today’s fast-paced technological landscape, industrial electronic assets such as Variable Speed Drives (VSDs), Programmable Logic Controllers (PLCs), and Human-Machine Interfaces (HMIs) face the imminent threat of obsolescence. This poses significant challenges for companies that rely on these systems for operational efficiency and productivity. As technology continues to advance at an unprecedented rate, understanding and managing industrial electronic asset obsolescence has become crucial for businesses aiming to maintain competitiveness and ensure operational continuity.

Understanding Electronic Asset Obsolescence

Asset obsolescence occurs when electronic equipment becomes outdated or loses its functionality over time. The primary causes of obsolescence include technological advancements, changing industry standards, limited support and service, and fluctuating market demand. These factors contribute to increased downtime, higher maintenance costs, operational inefficiency, and potential safety risks. Technological advancements drive businesses to upgrade to newer models that offer enhanced features and improved performance. As newer technologies emerge, older equipment becomes less efficient and may struggle to meet current performance and safety standards. Evolving industry standards can render older systems non-compliant, further reinforcing the need for upgrades.

Additionally, manufacturers often discontinue support for older models, making it increasingly difficult to find replacement parts or technical assistance. This limited support makes repairing obsolete equipment both costly and time-consuming. Furthermore, shifting market demands necessitate investment in newer technologies to meet evolving customer needs and operational requirements. To effectively combat obsolescence, businesses must proactively develop strategies to address these challenges before they worsen, rather than allowing equipment to degrade to the point of failure.

Consequences of Obsolescence

The consequences of obsolescence are significant and multifaceted. Aging equipment is more susceptible to failures, leading to increased downtime and costly production delays. Maintenance costs also rise as the scarcity of compatible parts drives up repair expenses. Companies often pay a premium for obsolete components, which strains budgets and operational resources. As aging systems become less reliable, businesses face the dual challenges of maintaining productivity and controlling operating costs. Furthermore, older systems often struggle to integrate with modern technologies, resulting in inefficient processes and reduced productivity.

This operational inefficiency not only hampers a company’s ability to remain competitive but can also negatively impact customer satisfaction and the bottom line. Safety risks are another major concern associated with obsolescence. Outdated systems may lack crucial safety features that modern equipment includes as standard, jeopardizing worker safety and the operational integrity of the business. In industries that prioritize safety, such as manufacturing and mining, adherence to stringent safety protocols is non-negotiable, and the use of outdated technology that fails to meet safety standards can have severe consequences. Proactively addressing obsolescence helps businesses avoid these pitfalls and maintain a safer, more efficient work environment.

Proactive Strategies to Mitigate Obsolescence

To mitigate the impacts of obsolescence, businesses can adopt several proactive strategies. Regular assessment of equipment is crucial to identify potential obsolescence issues before they worsen. Routine evaluations allow companies to stay ahead of problems and plan for necessary upgrades. By diligently monitoring the state of their assets, businesses can anticipate when components will need to be replaced or refurbished, ensuring minimal disruption to operations. Investing in refurbishment is another effective strategy.

Collaborating with specialized companies, such as Rom Control, can extend the lifespan of assets through electronic equipment refurbishment. This approach offers a cost-effective alternative to purchasing entirely new equipment and has the added benefit of reducing electronic waste. Proactive refurbishment not only preserves the functionality of existing systems but also ensures that they continue to meet current performance standards. This strategy is particularly beneficial for businesses operating with tight budgets, as it allows them to maintain productivity without the significant capital expenditure associated with purchasing new equipment.

Embracing New Technologies

Embracing new technologies, including IoT devices and AI, can enhance efficiency and prolong the life of existing assets. These technologies offer improved monitoring, predictive maintenance, and streamlined processes. By integrating IoT and AI solutions, businesses can gain real-time insights into their equipment’s condition, enabling proactive maintenance and reducing the likelihood of unexpected failures. Predictive maintenance, in particular, helps resolve issues before they cause significant disruptions, thus maximizing operational uptime.

Creating a pool of working spares is also a valuable strategy. Cataloging assets and promptly repairing failed equipment ensures a readily available pool of spares for rapid deployment, thereby minimizing downtime. This strategy allows businesses to quickly replace faulty components without having to wait for new parts to be ordered and delivered. Additionally, having a comprehensive inventory of spare parts and ensuring regular maintenance can further enhance operational resilience. Developing a strategic replacement plan is essential for budgeting and minimizing the impacts of obsolescence.

A well-structured replacement plan allows businesses to anticipate and budget for necessary upgrades, ensuring a smoother transition to newer technologies. By methodically planning the replacement of aging equipment, companies can allocate resources more efficiently and avoid the financial strain of last-minute, unexpected expenditures. This proactive approach to asset management not only preserves operational continuity but also positions businesses to adopt cutting-edge technologies as they become available.

The Role of Proactive Refurbishment

Proactive refurbishment plays a critical role in combating electronic asset obsolescence. By refurbishing existing equipment, companies can extend the life of costly electronic assets for a fraction of the OEM replacement costs. This approach not only provides significant cost savings but also contributes to environmental sustainability by reducing electronic waste. Refurbishment involves restoring equipment to its original specifications, often upgrading certain components to enhance performance and reliability. This process ensures that older systems can continue to operate effectively within the constraints of modern technological standards.

Rom Control, a company that has repaired and refurbished nearly 10,000 industrial electronic assets since 2007, exemplifies the benefits of proactive refurbishment. Serving sectors such as renewable energy, mining, and manufacturing, Rom Control extends the life of costly electronic equipment, often delivering faster turnaround times compared to acquiring new assets. The success of Rom Control demonstrates that refurbishment can serve as a viable and strategic solution for managing electronic asset obsolescence.

Strategic Planning for Obsolescence Management

In our fast-paced technological world, industrial electronic assets like Variable Speed Drives (VSDs), Programmable Logic Controllers (PLCs), and Human-Machine Interfaces (HMIs) face the constant risk of becoming obsolete. This creates significant challenges for companies that depend on these systems for efficiency and productivity. As technology rapidly advances, grasping the complexities of managing industrial electronic asset obsolescence is vital for businesses striving to stay competitive and ensure smooth operations.

Asset obsolescence can result in increased risks, including higher maintenance costs, reduced availability of replacement parts, and the need for staff training on new systems. Companies must therefore adopt proactive measures, such as implementing robust obsolescence management strategies, to mitigate these risks. This could involve regularly updating and upgrading systems, stockpiling critical spare parts, or investing in training for employees. By effectively managing obsolescence, businesses can maintain a competitive edge, reduce unexpected downtime, and ensure long-term operational continuity in a constantly evolving technological environment.