Micro-dispensing plays a pivotal role in numerous modern manufacturing processes, from applying sealants and glues to dispensing precise amounts of solder paste. The rapid evolution in technology has ushered in an era where precision and efficiency are paramount. One standout innovation driving this progress is the piezoelectric actuator. But how exactly do these actuators enhance micro-dispensing efficiency?

The Fundamentals of Piezoelectric Actuators

What Are Piezoelectric Actuators?

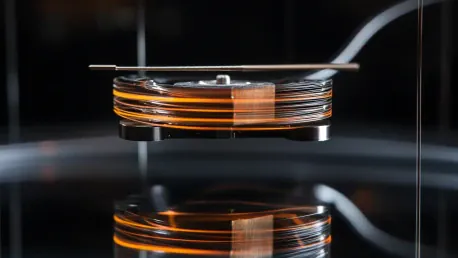

Piezoelectric actuators leverage the unique properties of piezoelectric materials, which deform when subjected to electrical voltages. This deformation is both rapid and precise, allowing for extremely fine control over movements. In micro-dispensing, this precision ensures that exact amounts of a substance are dispensed each time, significantly reducing waste and increasing consistency across the production line. The crystalline structure of piezoelectric materials is central to their functionality. When an electric field is applied, the alignment of charges within the crystal shifts, causing a change in shape. This change is reversible and can be repeatedly controlled with high accuracy, making piezo actuators a reliable choice for applications requiring repetitive motions.

The beauty of piezoelectric actuators lies in their ability to achieve precise and rapid movements without the mechanical complexity of traditional systems. This simplicity reduces the chances of mechanical failures and ensures long-term reliability. Whether dispensing micro-droplets of adhesives or consistent layers of solder paste, the reliability of piezo actuators means fewer production errors and a higher quality end product. As industries increasingly lean towards automation for efficiency, the role of piezoelectric actuators becomes even more crucial in maintaining the delicate balance between speed and precision.

Precision and Speed Advantages

One of the most significant benefits of piezoelectric actuators is their ability to operate at high speeds while maintaining precision. Unlike traditional mechanical systems that may falter under rapid cycles, piezo actuators can move in the sub-nanometer range and achieve frequencies up to several kHz. This capability is especially valuable in environments where quick, precise dosing is critical. The piezoelectric actuators’ speed advantage lies in their inherent ability to respond instantaneously to control signals, making them ideal for applications where time is of the essence.

The high-speed operation is accompanied by the ability to exert substantial force, ensuring that even highly viscous substances like thick glues and solder pastes are dispensed accurately. The combination of speed and precision translates to higher throughput and more efficient production processes, often becoming a key differentiator in competitive manufacturing sectors. This balance is particularly essential in industries such as electronics, where precise amounts of material must be applied rapidly to keep up with production demands. This ability to handle different viscosities without sacrificing performance further highlights the versatility and robustness of piezoelectric actuators in micro-dispensing applications.

Maintenance and Energy Efficiency

Durability and Maintenance-Free Operation

A notable advantage of piezoelectric actuators is their longevity and maintenance-free operation. Traditional actuators with mechanical gears wear out over time due to friction and repeated use. Piezoelectric actuators, however, lack these moving parts, significantly reducing the likelihood of breakdowns and the need for regular maintenance. By leveraging the piezoelectric effect, these actuators eliminate the common failure points found in mechanical systems, leading to enhanced durability.

Minimized wear and tear result in less downtime on production lines, which means higher overall efficiency and reduced operational costs. By avoiding frequent stop-and-go scenarios associated with maintenance, manufacturers can maintain a steady flow of production, enhancing overall productivity. This reliability is particularly useful in industries with high throughput requirements, where unplanned maintenance can significantly disrupt the production schedule. Furthermore, the reduced need for maintenance translates into lower labor costs and better allocation of personnel to other critical tasks, making piezo actuators an economically sound choice for manufacturers.

Energy Consumption

Another critical aspect of piezoelectric actuators is their energy efficiency. These actuators consume electricity only when moving and remain idle without power draw. This contrasts with other systems that may require constant energy to maintain their state. For companies focused on sustainability and reducing operational costs, this energy efficiency is a significant benefit. The power-saving nature of piezo actuators aligns with the broader industry trend toward greener and more sustainable manufacturing practices.

When not in use, piezo actuators revert to a zero-energy state. This energy-saving feature is particularly advantageous in high-volume production settings where energy costs can quickly accumulate. Over time, the reduction in energy usage contributes not only to cost savings but also to a smaller environmental footprint. This focus on sustainability while maintaining high performance further solidifies the standing of piezoelectric actuators as a forward-thinking choice in modern manufacturing. By embracing this technology, manufacturers can achieve their productivity goals without compromising their commitment to environmental stewardship.

Non-Contact Dispensing Methods

The Shift to Non-Contact Systems

In contemporary manufacturing, there is a noticeable shift towards non-contact dispensing methods. This transition is facilitated by technologies like PipeJet dispensers that utilize piezoelectric actuators for precise and efficient dosing. Non-contact dispensing reduces the risk of contamination and prevents damage to delicate components, which is crucial in industries such as pharmaceuticals and electronics. These non-contact systems ensure that materials are dispensed precisely where needed without physical interference, further improving product consistency and quality.

By employing non-contact methods, manufacturers can achieve a higher degree of control and uniformity in the dispensing process. This approach is particularly beneficial when working with intricate designs or intricate circuit boards, where even the slightest contact could affect the final product’s integrity. Additionally, non-contact dispensing allows for greater flexibility in design and layout, enabling manufacturers to create more complex and miniaturized components without risking contamination or mechanical interference. This level of precision and cleanliness is instrumental in sectors where even minor deviations can result in significant product failures or performance issues.

Handling Complex Substances

Piezoelectric actuators excel in handling not just standard fluids but also complex substances that include particulates like nanoparticle suspensions and paints. These materials often pose challenges for traditional dispensing systems, which may clog or fail to dispense accurately. With piezo actuators, the precise control over movement ensures that these materials are dispensed effectively without clogging. This capability is essential for manufacturers that work with advanced materials requiring meticulous handling and application.

The ability to handle a wide array of substances expands the versatility and applicability of piezoelectric actuators across different manufacturing sectors. This versatility makes them indispensable in applications where diverse materials are used, ensuring uniform quality and performance. Whether it’s dispensing biological substances in medical devices or applying conductive inks in printed electronics, piezoelectric actuators provide the adaptability needed to meet the varying demands of multiple industries. Their robustness and precision ensure reliable performance, maintaining high standards in manufacturing processes where quality control is imperative.

Challenges and Solutions in Operation

Self-Heating Considerations

Micro-dispensing is crucial in many modern manufacturing processes, such as applying sealants, glues, and accurately dispensing solder paste. With technology advancing rapidly, achieving high precision and efficiency has become essential. One significant innovation that has greatly enhanced these capabilities is the piezoelectric actuator. These actuators have become game-changers in the micro-dispensing field, but how exactly do they improve efficiency?

Piezoelectric actuators operate based on the piezoelectric effect, where certain materials produce an electric charge in response to mechanical stress. This attribute allows these actuators to provide highly precise and rapid movements. In micro-dispensing, this precision translates to the ability to dispense exact amounts of material consistently, which is critical for maintaining high-quality standards.

Moreover, piezoelectric actuators have a fast response time, enabling them to handle high-speed dispensing tasks effectively. Their ability to operate at microscale levels ensures minimal wastage of materials and optimal performance, which is especially important in industries like electronics and medical device manufacturing, where every drop counts.

In summary, the evolution of piezoelectric actuators has been instrumental in elevating micro-dispensing processes to new heights of precision and efficiency. By harnessing their unique properties, manufacturers can achieve superior control and accuracy, paving the way for advancements across various sectors.