In a world increasingly driven by technology, the issue of electronic waste (e-waste) has become a prominent concern, necessitating innovative solutions to manage its growing volume. One groundbreaking effort making strides in this domain is the partnership between the University of Portsmouth and Jiva Materials, aimed at developing and commercializing the world’s first biodegradable printed circuit boards (PCBs). According to The Global E-Waste Monitor 2019, each individual contributes approximately 7.5 kilograms of e-waste annually, a figure that’s steadily climbing. Reflecting this trend, Australia alone generated 511,000 tonnes of e-waste in 2019—a number projected to balloon by 30 percent to 657,000 tonnes by 2030.

The Traditional E-Waste Dilemma

Persistent Problems with Conventional Materials

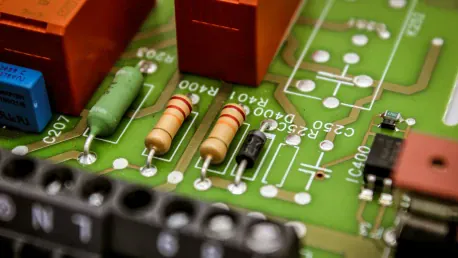

Traditional circuit boards, which have largely remained unaltered for the past 70 years, are constructed using glass fiber epoxy laminate and persistent organic pollutants as flame retardants. This outdated composition poses significant recycling challenges, often leading to inadequate disposal methods that either landfill or incinerate valuable metals such as gold, silver, and platinum. This approach not only squanders precious resources but also contributes to environmental pollution and the overall carbon footprint of electronic products.

The limitations of conventional circuit boards in terms of recyclability have necessitated alternative approaches. Jiva Materials’ groundbreaking solution, a novel laminate known as Soluboard, aims to significantly address these issues by reducing both carbon emissions and the loss of critical minerals. Soluboard’s biodegradable nature provides an ecologically sound method to handle circuit board disposal, marking a significant departure from the environmentally harmful practices tied to traditional PCBs.

The Environmental Impact of E-Waste

The environmental and societal costs of e-waste are immense, presenting an urgent need for sustainable solutions. When traditional PCBs end up in landfills or are incinerated, they release harmful pollutants and toxic metals, posing severe health risks to communities near disposal sites. The leaching of hazardous substances into the soil and water further exacerbates environmental degradation.

By introducing biodegradable materials into the composition of PCBs, the collaboration between the University of Portsmouth and Jiva Materials showcases a proactive approach to reducing the negative impact of e-waste. This initiative not only aims to mitigate pollution but also promotes a circular economy, where resources are recycled and reused instead of discarded. The development of Soluboard exemplifies how innovative research and industrial collaboration can result in technology that is both functional and environmentally responsible.

The Role of Innovation and Collaboration

Pioneering Research at University of Portsmouth

Leading the charge in this innovative endeavor is Prof. Hom Dhakal and his team at the University of Portsmouth’s School of Mechanical and Design Engineering. Supported by a Knowledge Transfer Partnership (KTP) from Innovate UK, the team is investigating natural fibers such as jute, flax, and hemp as potential laminate materials for Soluboard. The research focuses on the mechanical properties, durability, and environmental benefits of these natural fibers to determine their suitability for advanced electronic applications.

This partnership is an exemplary model of how academic research can effectively collaborate with industry to create breakthrough technologies. By assessing the viability of these natural fibers, Prof. Dhakal and his team aim to expedite the advancement and commercial adoption of Soluboard. This innovative material is expected to perform as well as, if not better than, traditional materials in various electronic applications, thereby reinforcing the feasibility of biodegradable PCBs in the mainstream market.

Sustainability Goals and Future Prospects

Dr. Jonathan Swanston, CEO of Jiva Materials, underscores the alignment of this initiative with his company’s long-term sustainability vision. The development of Soluboard is not just a technological advancement; it is a crucial step towards establishing a sustainable lifecycle for electronic products. Prof. Dhakal also emphasizes the university’s commitment to environmental sustainability and innovation, stating that the research aligns perfectly with their broader goals.

Both partners have high hopes that this collaboration will significantly contribute to sustainable materials and enhance circularity in the electronics sector, addressing a pivotal aspect of the e-waste problem. They believe that the commercial success of Soluboard will pave the way for wider adoption of eco-friendly materials in the electronics industry, inspiring other companies to invest in sustainable technologies.

Moving Towards a Sustainable Future

Addressing the Global E-Waste Challenge

The collaboration between the University of Portsmouth and Jiva Materials marks a monumental step in addressing the global e-waste challenge. As e-waste figures continue to rise, the need for sustainable solutions becomes increasingly pressing. Biodegradable PCBs like Soluboard offer a promising alternative, capable of significantly reducing the environmental impact of discarded electronic components. The initiative represents a shift towards more sustainable manufacturing practices within the electronics industry.

The progress achieved through this partnership serves as an inspiration for further research and development in sustainable technologies. By fostering cooperation between academia and industry, innovative solutions to combat e-waste can be realized more efficiently and effectively. The success of Soluboard could potentially lead to broader changes in e-waste management policies and practices worldwide.

The Broader Impact of Sustainable Technologies

In today’s tech-driven world, the mounting issue of electronic waste (e-waste) has become a significant worry, urging the need for innovative solutions to address its escalating volume. A noteworthy initiative making headway in this field is the collaboration between the University of Portsmouth and Jiva Materials. They are focused on creating and commercializing the world’s first biodegradable printed circuit boards (PCBs). According to The Global E-Waste Monitor 2019, each person generates about 7.5 kilograms of e-waste per year, a number that’s on the rise. Reflecting this upward trend, Australia alone produced 511,000 tonnes of e-waste in 2019. This figure is expected to increase by 30 percent, reaching 657,000 tonnes by 2030. This alarming increase underscores the urgency for sustainable solutions like the biodegradable PCBs being developed. By pioneering such technology, the University of Portsmouth and Jiva Materials aim to reduce the environmental impact of e-waste, offering a promising path forward in the realm of sustainable electronics.