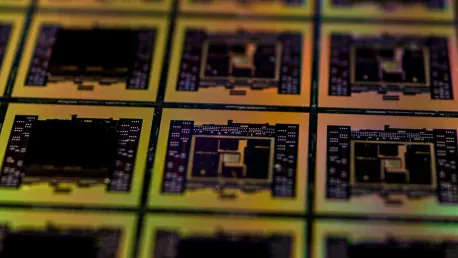

In semiconductor manufacturing, metal etching is a critical process where thin metal layers on semiconductor wafers are patterned to define circuit structures. The Applied Materials Centura 5200 DPS+ is a cutting-edge system employing Plasma Etching to precisely remove metal from wafer surfaces. Metal etching is pivotal in producing integrated circuits (ICs) with the desired functionality and performance. As the industry evolves, there’s an increasing need for more advanced, accurate, and efficient metal etching solutions. The Centura 5200 DPS+ addresses these needs with high precision and control, crucial for fabricating advanced semiconductor nodes where even minor variations can lead to defects and reduced yields.

The Role of SECS/GEM in Semiconductor Manufacturing

SECS/GEM (Semiconductor Equipment Communication Standard / Generic Equipment Model) plays a vital role in enhancing the coordination and function of semiconductor manufacturing equipment. Through the SECS/GEM protocol, devices like the Centura 5200 DPS+ can connect effectively with other devices and central control systems within the factory. This seamless communication is essential for maintaining efficiency and consistency, as it facilitates real-time monitoring of critical process parameters such as temperature, pressure, and etching duration.

By enabling such comprehensive monitoring, SECS/GEM allows manufacturers to promptly detect and address anomalies, ensuring high-quality etching results and minimizing defects. This capability, by reducing human error and improving process consistency, is indispensable in high-volume production environments. Furthermore, SECS/GEM supports significant automation and control advantages. Automated adjustments based on continuous data feedback streamline processes, enhancing overall production efficiency. It ensures seamless integration with metrology systems, material handling equipment, and inspection tools, thereby creating a fully interconnected and automated manufacturing environment.

Benefits of SECS/GEM Integration

Integrating SECS/GEM with the Centura 5200 DPS+ brings many benefits, significantly enhancing overall manufacturing efficiency from wafer handling to post-etch inspection. By facilitating real-time data monitoring, this integration allows manufacturers to promptly detect and address anomalies, ensuring high-quality etching outcomes and minimizing defects. Additionally, the system enables automated adjustments based on continuous data feedback, significantly reducing human error and improving process consistency.

SECS/GEM’s ability to generate comprehensive data reports is invaluable for manufacturers, aiding in quality control, regulatory compliance, and process optimization. These detailed reports help identify trends and pinpoint areas for improvement, ensuring consistent and high-quality output. Moreover, SECS/GEM ensures seamless integration with metrology systems, material handling equipment, and inspection tools, creating a fully automated and interconnected manufacturing environment. This level of integration allows for substantial efficiency improvements and streamlined operations, which are crucial in a highly competitive industry.

The Centura 5200 DPS+: A High-Precision Metal Etching Solution

The Applied Materials Centura 5200 DPS+ is recognized as a leading tool for metal etching in semiconductor manufacturing. It uses Deep Plasma Source (DPS) technology to achieve high precision and control over the etching process, crucial for fabricating advanced semiconductor nodes where even minor variations can lead to defects and reduced yield. The versatility of the Centura 5200 DPS+ is one of its significant advantages, as it supports various metal etching processes and handles different materials such as copper, tungsten, and aluminum. This flexibility makes it suitable for both 200mm and 300mm wafers, meeting different production requirements and allowing for a broad range of applications.

In terms of performance, the Centura 5200 DPS+ delivers rapid processing without compromising etch quality, essential for meeting high-volume production demands. The system offers precise control over parameters like etching power, pressure, and temperature, resulting in cleaner etches, fewer defects, and improved pattern fidelity. This degree of control contributes to the tool’s ability to ensure highly uniform etching results, necessary for manufacturing semiconductors with tight tolerances. Additionally, designed for high uptime and low ownership costs, the Centura 5200 DPS+ emerges as an ideal choice for optimizing production line efficiency.

The Significance of the EIGEMBox

The EIGEMBox serves as an essential communication interface, bridging the Applied Materials Centura 5200 DPS+ with the factory’s control systems. It facilitates accurate, real-time data exchange, thereby enhancing the overall efficiency of the metal etching process. By ensuring accurate transfer of all data generated during the metal etching process to the central system, the EIGEMBox significantly enhances monitoring and control capabilities. It provides a real-time connection for quick detection of issues or inconsistencies, enabling proactive troubleshooting and minimizing downtime.

In addition to enhancing data transfer and troubleshooting capabilities, the EIGEMBox facilitates seamless integration of the etching tool with other automated systems, ensuring optimal performance adjustments without manual intervention. This increased process automation allows for smoother operations and greater efficiency, crucial in a highly competitive manufacturing environment. Additionally, by allowing operators to oversee the entire production line from a single point, the EIGEMBox contributes to informed decision-making and process optimization, ensuring consistent and high-quality output.

Conclusion: Enhancing Semiconductor Manufacturing with SECS/GEM and the Centura 5200 DPS+

In semiconductor manufacturing, metal etching plays a vital role. It involves patterning thin metal layers on semiconductor wafers to form circuit structures. The Applied Materials Centura 5200 DPS+ is a state-of-the-art system using Plasma Etching to meticulously strip metal from wafer surfaces. This metal etching process is essential in creating integrated circuits (ICs) with the desired functionality and efficiency. With the industry’s constant evolution, there’s a growing demand for more advanced, precise, and efficient metal etching techniques. The Centura 5200 DPS+ meets these demands with exceptional precision and control, which is crucial for developing advanced semiconductor nodes. Minor variations during this stage can lead to significant defects and lower yields. Thus, the Centura 5200 DPS+ is designed to eliminate these variations, ensuring high quality and performance in semiconductor production. This advanced system not only enhances accuracy but also boosts production efficiency, making it invaluable for modern manufacturing processes.