The long-standing model of food safety, which has historically relied on reacting to contamination events after they have already occurred, is on the cusp of a revolutionary transformation driven by the integration of artificial intelligence. This technological shift is poised to fundamentally reshape the industry by enabling a move from a reactive posture to a proactive and predictive framework that anticipates and neutralizes potential hazards before they can compromise public health. Far from replacing human oversight, AI is emerging as a powerful collaborative tool designed to augment the capabilities of highly trained food safety professionals. By leveraging its analytical power, organizations can strengthen their food safety culture—the collection of shared values, beliefs, and practices that prioritize consumer well-being—and embed these principles more deeply and effectively into every facet of their operations, heralding a new standard of security for the global food supply.

From Reaction to Prediction

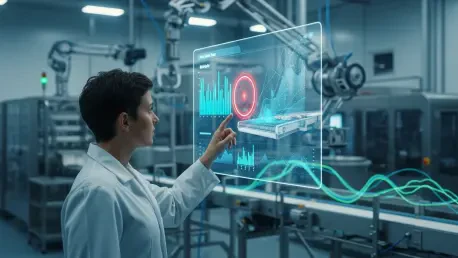

The most profound impact of artificial intelligence on food safety lies in its capacity to cultivate a genuinely predictive and proactive strategy. By continuously analyzing immense streams of real-time data from sensors strategically placed throughout the production line, AI algorithms can detect subtle deviations from established safety parameters. This allows for the identification of potential contamination risks, impending equipment malfunctions, or procedural inconsistencies long before they escalate into serious incidents. This fundamental shift from after-the-fact problem-solving to forward-looking prevention is the cornerstone of a more resilient and effective food safety culture. This proactive stance not only minimizes the risk of product recalls and public health crises but also fosters an environment where continuous improvement is driven by data-informed foresight rather than costly and damaging failures.

Furthermore, AI introduces unprecedented levels of efficiency by automating a wide range of time-consuming and labor-intensive tasks that have traditionally burdened food safety teams. These include the complex analysis of microbial data to pinpoint the root cause of an issue, the interpretation of dense and frequently updated regulatory documents, and the ceaseless monitoring of critical control points. By shouldering these manual workloads, AI liberates human experts to concentrate on higher-value activities such as strategic planning, process optimization, and complex problem-solving. This evolution cultivates a culture of insightful analysis and strategic action, moving beyond mere data collection to a deeper understanding of operational dynamics. As a result, teams become more agile and forward-thinking, using their expertise to innovate and strengthen safety protocols rather than being mired in routine monitoring.

Enhancing Precision and Human Performance

The integration of advanced AI tools like computer vision significantly mitigates the risk of human error by introducing a level of precision and consistency that is difficult for people to maintain over extended periods. These sophisticated systems can perform tireless inspections, identifying microscopic contaminants on products, verifying that employees are adhering to critical hygiene protocols such as proper handwashing, and detecting subtle anomalies in equipment that are invisible to the naked eye. This constant, unbiased vigilance helps foster a culture of precision and accountability, where adherence to the highest standards is systematically enforced. This capability empowers even smaller teams to manage comprehensive safety measures with exceptional effectiveness, ensuring that nothing is overlooked and that every step of the production process aligns with rigorous safety requirements.

In addition to enhancing operational precision, artificial intelligence is set to revolutionize how employees are trained and how positive behaviors are reinforced on the job. Vision AI systems can provide immediate, constructive feedback to workers on the production floor, helping to correct improper techniques in real-time and preventing bad habits from forming. Training modules can be dynamically tailored to an individual’s specific role, learning pace, and performance needs, ensuring that knowledge is not only acquired but also effectively applied in their daily tasks. This continuous, personalized feedback loop helps solidify best practices until they become ingrained habits, transforming safety protocols from abstract rules into tangible, consistently executed behaviors. This approach nurtures a culture of continuous learning and personal responsibility, where every employee is an active participant in maintaining a safe environment.

Navigating the Challenges of Integration

Despite its transformative potential, the widespread adoption of AI in food safety is not without significant hurdles, with the primary challenge being the quality of the data it relies on. The effectiveness of any AI system is directly contingent on the accuracy, completeness, and lack of bias in the data it is fed. Inaccurate or incomplete information can lead AI to generate flawed risk assessments and erroneous conclusions, which could not only undermine trust in the technology but also lead to catastrophic public health failures. Another major barrier is the substantial financial investment required to implement advanced AI systems. This cost could create a “digital divide” within the industry, allowing large corporations to leverage these powerful tools while smaller and medium-sized enterprises are left behind, perpetuating a reliance on less effective manual processes and creating dangerous inconsistencies in safety standards across the supply chain.

Beyond the technical and financial barriers, the integration of AI is also complicated by significant regulatory and accountability gaps. The legal landscape governing the use of AI in food safety is still in its infancy, creating uncertainty and slowing adoption. This lack of clear guidance, combined with the fact that many seasoned food safety experts are not well-versed in AI, creates challenges in validating AI-generated results and integrating them into established Hazard Analysis and Critical Control Points (HACCP) systems. Furthermore, the potential for AI to produce false data, often referred to as “hallucinations,” poses a serious risk. If a team acts on incorrect information provided by an AI, it could trigger a public health crisis and raise complex questions of accountability, potentially weakening the culture of personal responsibility that is central to food safety.

A New Era of Human-Machine Collaboration

Ultimately, the successful integration of AI into the food safety ecosystem depended on viewing it not as a replacement for human expertise but as an invaluable co-pilot. The industry consensus solidified around the idea of AI as a tireless and exceptionally intelligent teammate that augmented, rather than supplanted, the critical thinking and experience of trained professionals. By processing and identifying patterns in massive volumes of unstructured data—from supplier reports and maintenance logs to customer feedback—AI uncovered hidden trends and correlations, empowering teams with deeper, more actionable insights. This capability fostered a culture of curiosity and data-driven exploration, where human judgment was sharpened by machine intelligence. This synergy led to better-informed decisions, a more secure food supply, and a tangible increase in consumer trust, proving that the technology’s greatest value was realized in partnership with human oversight and expertise.