The relentless drive to automate and optimize the modern factory floor has created an unprecedented paradox where the very technologies designed to enhance efficiency are simultaneously exposing the manufacturing sector to catastrophic digital threats. As the industry aggressively pursues digital transformation through the adoption of artificial intelligence and cloud-based systems, a dangerous disconnect has emerged. The pace of this technological integration is far outstripping the implementation of necessary security measures, leaving manufacturers profoundly vulnerable to increasingly sophisticated cyberattacks. Cybersecurity experts have reached a clear consensus that security has become a hazardous afterthought in the race to modernize, creating a fertile ground for cybercriminals to exploit a foundational pillar of the global economy. This oversight is not a minor issue but a systemic weakness that threatens production lines, supply chains, and the financial stability of companies large and small.

The Staggering Price of Negligence

A stark illustration of this vulnerability was the major cyberattack on automobile manufacturer Jaguar Land Rover, which forced a month-long shutdown of its production lines and revealed the immense financial and operational consequences of a breach. The direct financial fallout was staggering, with the company reporting approximately $260 million in cybersecurity costs. This figure was compounded by an additional $650 million in losses stemming from the severe production disruption, U.S. tariffs, and the phasing out of older vehicle models. The operational impact was equally severe, halting highly automated UK production lines that typically produce around 1,000 vehicles daily. This shutdown sent disruptive shockwaves throughout its extensive global supply chain. The incident also carried significant human and economic consequences, as unions and officials estimated that thousands of workers faced potential layoffs and smaller suppliers were at risk of bankruptcy due to the abrupt and prolonged loss of business, demonstrating how a single digital failure can cascade into a real-world crisis.

This event is not an isolated incident but a symptom of a much broader and more alarming trend. The manufacturing sector has become the primary target for cybercriminals for four consecutive years, a finding highlighted in the IBM X-Force Threat Intelligence Report 2025 and echoed by Black Kite’s 2025 Manufacturing Report. The industry’s rapid digitization is a key contributing factor to this unfortunate distinction. A 2025 Deloitte Smart Manufacturing Survey of 600 executives at large U.S. manufacturing companies found that 57% were already using cloud systems, and 29% were leveraging artificial intelligence and machine learning at the facility or network level. Furthermore, North America’s dominance in the cloud-based manufacturing infrastructure market, accounting for nearly 50% of the global share in 2024, underscores the sheer scale and speed of this technological transition. This rapid adoption, while beneficial for productivity, has inadvertently created a vast and attractive landscape for threat actors seeking to exploit nascent security protocols.

A Foundation Built on Fragile Ground

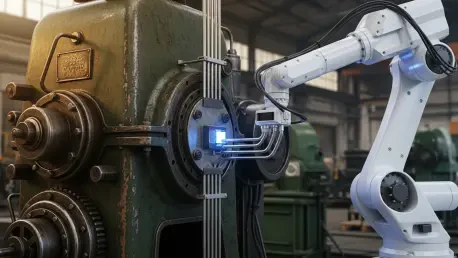

Experts identify the core of the problem as a fundamental mismatch between modern, hyper-connected technology and the legacy infrastructure upon which it is being built. Nick Nolen, vice president of cybersecurity strategy and operations at Redpoint Cyber, asserts that the “biggest cybersecurity risk in manufacturing right now comes from the amount of connectivity being introduced into environments that were never designed for it.” Historically, manufacturing systems and operational technology were designed to be physically isolated, running offline and optimized purely for performance and physical output. Todd Moore, VP of encryption at Thales, notes that cybersecurity was never a consideration in their original design. Now, as companies attempt to integrate advanced AI and cloud technologies with this old infrastructure, they create systemic weaknesses. Security is often “bolted on” as a reactive measure rather than being embedded from the ground up through “secure-by-design” principles, leaving companies critically exposed to a wide array of attacks, including ransomware, malware, phishing, and denial-of-service.

The adoption of AI and cloud systems specifically amplifies these existing risks by dramatically expanding the potential “attack surface” of a manufacturing operation. Nolen explains that modern manufacturing’s reliance on a complex and interconnected ecosystem of third-party integrators, internet-connected machines, vendor-supplied software, and inter-departmental data exchanges creates numerous potential entry points for attackers. The highly integrated nature of these systems means that once a threat actor gains a foothold in even a peripheral area, such as a supplier’s network or an administrative system, they can often move laterally with alarming speed toward more critical and sensitive operational technology on the factory floor. As more manufacturing data—from proprietary designs and intellectual property to precise production parameters—is moved into the cloud to power AI algorithms and automation, these cloud systems are transformed into larger and more attractive targets for cybercriminals seeking high-value information.

Navigating the New Threat Landscape

According to Kevin Albano, global head of X-Force Threat Intelligence at IBM, the most significant risk is the potential for unauthorized access to the troves of sensitive data that manufacturers upload to these new systems. Compounding this issue is the informal use of AI and cloud tools by employees without oversight from security teams, which creates major blind spots in a company’s defense. Ferhat Dikbiyik, chief research and intelligence officer at Black Kite, points out that security teams often do not know what sensitive design or process information is being uploaded by employees, which third-party AI models their vendors are using, or how these external systems could potentially connect back to core operational technology. This pervasive lack of visibility is a critical failure. Nolen adds that companies must have clear guidelines about data handling, asking crucial questions about their vendors: “Do you know what your vendor is doing with that data? Do you know where it is stored? How long is it retained? Is it being used to train their own models?”

To counter these escalating threats, experts propose a multi-faceted and proactive cybersecurity strategy that begins with a fundamental shift in perspective. A foundational element of this strategy is to treat data as a high-value asset that requires stringent protection. Albano recommends a rigorous approach that includes classifying all data based on its sensitivity, from public information to top-secret intellectual property. This classification then dictates the level of security applied, including the encryption of personally identifiable and proprietary information both when it is at rest in storage and when it is in transit across networks. Implementing strong key management protocols is also critical to ensure that even if data is intercepted, it remains unreadable. Moore echoes this, stating that organizations should begin their security journey by thoroughly classifying data and conducting comprehensive risk assessments to pinpoint the most pressing vulnerabilities within their hybrid and cloud environments.

Fortifying the Digital Factory

Another critical defense that proved essential was robust network segmentation. Dikbiyik warned that cloud systems centralize valuable information, meaning a single compromised account could potentially cripple multiple plants simultaneously. To mitigate this, he strongly advised that companies needed proper segmentation between their information technology (IT), cloud, and operational technology (OT) systems so that a breach in a digital tool could not cascade into physical production. This involved creating digital firewalls that prevented an attack on a corporate email system, for instance, from spreading to the machinery and control systems on the factory floor. This separation was crucial for containing threats and protecting the core operational integrity of the manufacturing process from the inherent risks of a more connected corporate environment. These measures ensured that a security event in one domain remained isolated and manageable.

Finally, while the significant upfront costs of robust security systems often presented a deterrent, a strategic approach to investment was recognized as essential for long-term resilience. Nolen advised that simply increasing expenditure did not equate to better security. Instead, he recommended that manufacturers calculated the probable financial loss in the event of various attack scenarios. This risk-based analysis allowed them to make informed decisions about security spending, balancing the cost of proactive investment against the potentially catastrophic costs of a successful cyberattack. The ultimate challenge lay in weighing the cost of continuously evolving cybersecurity programs against the ever-present risk of a breach. As Dikbiyik concluded, the goal was never to slow innovation, but to ensure that the digital factory of the future was built on a security model that matched its immense complexity and potential.