The modern manufacturing landscape is undergoing a fundamental reevaluation of its core principles, moving decisively away from a historical model where quality control was little more than a final inspection at the end of a production line. This traditional, reactive approach has proven to be an inherently inefficient and costly paradigm, often identifying defects only after significant resources have already been invested in a flawed batch. The contemporary approach redefines quality not as a static, post-production checkpoint but as a dynamic, continuous process variable that must be proactively managed in real time. In this evolved model, the primary objective for manufacturers is to prevent variation before it occurs, thereby mitigating downstream costs related to rework and scrap while ensuring unwavering product integrity from the very beginning of the production cycle. This shift from reactive correction to proactive prevention is not merely an incremental improvement but a complete transformation in operational philosophy, driven by the need for greater efficiency, consistency, and profitability in an increasingly competitive global market.

The Unseen Driver of Manufacturing Efficiency

Central to this new quality paradigm is the growing recognition of moisture content as one of the most influential and critical process variables across a vast spectrum of industries. In countless manufacturing processes, particularly in food and beverage production, moisture is a primary determinant of overall efficiency, final product integrity, production throughput, and energy consumption. Even seemingly minor deviations in moisture levels can trigger significant and far-reaching consequences, marking the difference between a product that is perfectly processed and one that is rendered unusable due to being undercooked, overly moist, or brittle. The cascading effects of inconsistent moisture control permeate every facet of an operation, directly contributing to increased rates of rework, wasted materials, excessive energy usage during heating or drying stages, higher levels of scrap, and general product inconsistencies that ultimately erode profitability and tarnish brand reputation, making its precise control an economic imperative.

Despite its profound impact on operational outcomes, many facilities continue to manage this critical parameter using outdated and inefficient methods that are fundamentally at odds with the demands of modern production. Traditional approaches, which often rely on intermittent laboratory sampling, the subjective judgment of line operators, or after-the-fact quality inspections, are inherently slow and reactive. Consequently, a significant volume of material is often already out of specification by the time a problem is detected, forcing the facility into a costly and disruptive damage control mode. This reactive cycle perpetuates waste and inefficiency. The pivotal solution lies in a strategic shift toward continuous, real-time monitoring, a technological leap that reframes moisture from an unpredictable byproduct of production into a deliberately controllable performance parameter. This transformation allows manufacturers to directly influence cost, enhance sustainability, and achieve unprecedented levels of process repeatability in highly measurable ways.

A Foundation for Modern Quality Systems

A core advantage of continuous moisture monitoring is its ability to provide the essential, real-time data necessary to effectively implement and act upon established best-practice quality frameworks such as ISO 9001 and Six Sigma. These systems have long defined the principles for reducing variation and improving predictability, but their efficacy is entirely dependent on the availability of accurate, continuous data streams. For ISO 9001, which places a strong emphasis on standardization, consistency, and ultimate customer satisfaction, continuous measurement offers direct and tangible support. By ensuring that moisture content is consistently maintained within precise, documented thresholds across every shift, production line, or raw material batch, manufacturers can achieve the high level of standardization that the framework demands. This real-time data also empowers operators to identify and correct subtle deviations as they happen, rather than waiting for those deviations to manifest as visible defects in the final product, thus upholding the core principle of proactive quality assurance.

The connection to Six Sigma and its underlying philosophy is even more explicit and fundamental. The central tenet of Six Sigma is the relentless reduction of process variation, an objective that is impossible to achieve without a solid foundation of accurate and continuous data. Continuous moisture measurement provides exactly this foundation, allowing facilities to quantify trends in real time and make immediate, data-driven adjustments. This replaces guesswork and post-manufacturing analysis with a statistically informed decision-making process. By addressing variability at its source rather than downstream, manufacturers can drastically reduce defects and improve their first-pass yield, a primary goal of any Six Sigma initiative. Furthermore, this level of real-time control aligns perfectly with broader lean manufacturing goals, establishing a direct link between moisture management and the core lean tenets of waste reduction. Materials processed outside of their optimal moisture range lead to energy waste, extended cycle times, and increased scrap, all of which are antithetical to lean principles.

The Data-Driven Transformation

As manufacturing operations become increasingly global and distributed, the principles of traceability and standardization have transitioned from best practices to essential requirements for success. Continuous moisture data provides a clear and reliable pathway to achieving consistent product outcomes across multiple production sites, diverse teams, and varied raw material sources. This technology generates time-stamped records and actionable feedback loops, giving manufacturers a complete and detailed historical log of moisture performance at every critical stage of production. This detailed data logging provides robust support for compliance in highly regulated industries, such as food and pharmaceuticals, where complete process traceability is mandatory. It also serves as the evidentiary basis for establishing and enforcing standard operating conditions across an entire enterprise, replacing reliance on assumptions with a foundation of hard evidence and leading to a more uniform product profile.

Just as importantly, this data-driven approach yields significant and measurable sustainability benefits that align with both economic and environmental objectives. Moisture levels have a direct and undeniable correlation with energy usage and resource efficiency. When materials are processed at their optimal moisture content, drying and heating stages require substantially less thermal energy and can be completed in a shorter amount of time, resulting in significant energy savings and lower operational costs. Concurrently, scrap rates decline because moisture-related quality issues are identified and corrected long before the final inspection stage. The cumulative effect of reduced rework, material waste, and product rejects is a marked improvement in both operational profitability and environmental stewardship, demonstrating that efficient production and sustainable practices are not mutually exclusive goals but are, in fact, deeply intertwined through intelligent process control.

A New Era of Process Control

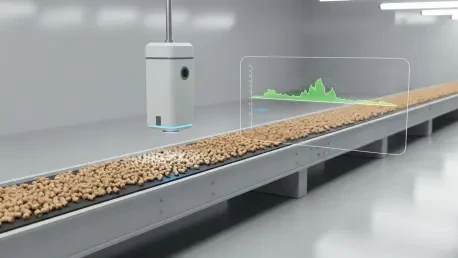

This evolution in moisture control was made possible by the refinement of advanced near-infrared (NIR) technology. Modern NIR sensors allow for the continuous, non-contact measurement of moisture in real time as materials move along a production line. Instead of interrupting the process for manual sampling, operators receive instant, actionable feedback that can be fed directly into automated control systems to make immediate adjustments. Industrial-grade NIR systems are designed to deliver reliable and repeatable data regardless of common process variations such as changes in material color, thickness, particle size, or flow height. These systems require minimal calibration and can be strategically positioned at multiple critical points in the production line, enabling sophisticated closed-loop control and continuous process optimization that was previously unattainable, thereby unlocking a new level of operational intelligence and responsiveness for manufacturers.

Once this technology was implemented, the operational and economic benefits proved to be both immediate and profound. Facilities that integrated real-time monitoring saw their energy consumption drop as drying steps became more efficient and targeted. Product quality improved as moisture-related defects were prevented at their point of origin, leading to a dramatic decline in scrap and rework rates. Consequently, labor hours previously dedicated to manual sampling and offline lab measurements were redirected to more value-added tasks that directly increased throughput. This shift cultivated a new level of operational predictability, empowering manufacturers to anticipate where variability was likely to occur and control it at the source. The adoption of continuous moisture monitoring became a standard, integrated practice that fundamentally changed the meaning of quality control, providing not just better products, but comprehensive command over the entire production system.