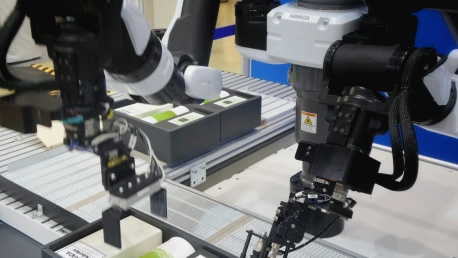

The rise of digital technology heralded the Fourth Industrial Revolution, transforming manufacturing with the emergence of smart factories. These advanced production environments prioritize flexibility, efficient use of resources, and improved working conditions. However, their reliance on interconnected systems and automation also makes them vulnerable to cyber threats.To combat these risks, smart factories must adopt robust cybersecurity measures. One strategy entails deploying sophisticated firewalls and intrusion detection systems to shield the industrial control systems. Regular security audits and updates are crucial to keeping defenses current against emerging threats.Employees also play a vital role in maintaining cybersecurity. Comprehensive training programs can equip them with the skills to recognize potential threats and follow best practices for digital safety.Moreover, there is a need for constant vigilance through real-time monitoring, which can detect and respond to incidents promptly. The use of encrypted communications and secure access controls can prevent unauthorized access and data breaches.Another layer of security can be added by implementing secure protocols for third-party vendors, ensuring that their systems do not become gateways for attacks.By combining these strategies, smart factories can create a resilient shield against cyber threats, preserving the integrity of their operations and maintaining trust in the era of intelligent manufacturing.

The Cybersecurity Challenges of Smart Factories

Intersection of IT and OT in Manufacturing

As smart factories evolve, the lines between Information Technology (IT) and Operational Technology (OT) are blurring due to the adoption of Internet of Things (IoT) devices and cloud computing. This integration is designed to boost efficiency but also widens the potential points of entry for cyber-attacks. While in the past IT and OT operated as distinct silos with separate security measures, their convergence means that now a breach in one can easily affect the other.The prior separation between IT and OT afforded a level of security through isolation; however, today’s intertwined systems create a complex landscape where risks are amplified because an entire integrated environment could be compromised from a single weak link. As factories become more connected, protection against cyber threats becomes more challenging and necessitates a comprehensive approach to security that encompasses the new reality of these converged systems.This shift demands that companies rethink their cybersecurity strategies. Establishing robust and resilient safeguards to address the expanded attack surface is critical in mitigating risks. As organizations harness the potential of smart factory technologies, they must also prioritize the development of advanced security protocols that can adapt to the changing nature of IT/OT integration, ensuring that operational continuity and data integrity are maintained in an era of digital manufacturing.

The Misalignment of IT and OT

The growing intersection of Information Technology (IT) and Operational Technology (OT) in smart factories is raising significant cybersecurity issues. Traditionally separate, OT systems on the production floor are now vulnerable to IT-targeted cyber threats due to increased connectivity. Addressing these risks requires a unified cybersecurity strategy that merges IT’s protective measures with OT’s focus on durability and safety. Implementing such a strategy is challenging, owing to the long-standing separation between the two areas and a company culture not accustomed to collaborative security planning. The disparity between IT and OT security needs and technologies complicates the creation of an integrated governance model. For today’s manufacturers, it’s essential to overcome these challenges and forge a comprehensive, cohesive approach to cybersecurity that effectively secures both IT and OT assets.

Evaluating Cybersecurity Preparedness in Manufacturing

Perception Versus Reality of Cybersecurity Maturity

Manufacturers often feel equipped to tackle cybersecurity threats, believing their detection and response systems are up to the task. However, reality paints a different picture, indicating a significant discrepancy between their confidence and actual cybersecurity readiness. While they may have incident detection mechanisms, full-scale evaluations of their security measures are infrequent.This overconfidence leads to a deceptive sense of security and leaves firms vulnerable to cyberattacks, especially when integrating new technologies. Frequently, the cybersecurity implications of these technologies are not fully understood or considered. As a result, sectors adopting advanced technological solutions may inadvertently expose themselves to new risks without even realizing it.The crux of the issue lies in the need for comprehensive and regular cybersecurity assessments that keep pace with technological advancements and evolving digital threats. By regularly auditing and updating their cybersecurity strategies, manufacturers can gain a more accurate picture of their preparedness. It is not enough to install security tools; organizations must thoroughly understand and continually address the ever-changing landscape of cybersecurity threats. Closing this gap between perceived and actual security postures is critical for safeguarding against the increasingly sophisticated array of cyber threats facing modern industries.

Risk Assessment and Monitoring Challenges

Cybersecurity assessments are vital yet often neglected in ensuring the security of smart factories. With advancing technologies and more adept cyber adversaries, these evaluations are essential to preempt potential vulnerabilities. Nonetheless, these assessments are frequently not as thorough or regular as they should be. This is especially true for Operational Technology (OT) environments, which may not receive the same rigorous, ongoing scrutiny as Information Technology (IT) assets.The lack of attention to the specific needs of OT systems poses significant risks, since an attack could lead to more than data breaches—it could interrupt actual physical operations. To mitigate these risks, it is crucial that cybersecurity assessments for smart factories encompass both IT and OT assets with equal granularity and are conducted at regular intervals to keep pace with evolving threats. By doing so, manufacturers can identify weaknesses before attackers do, safeguarding against disruptions that could have far-reaching consequences on production and safety. It is imperative for the future of manufacturing that cybersecurity assessments evolve to provide a comprehensive shield against the multifaceted nature of cyber threats in an increasingly connected industrial landscape.

Constructing a Proactive Cybersecurity Strategy

Essential Steps for Greater Cyber Resilience

In the face of evolving digital threats, manufacturers must adopt a forward-thinking stance on cybersecurity. This proactive strategy begins with assessing their security posture to understand their strengths and weaknesses in protecting both Information Technology (IT) and Operational Technology (OT) systems. A comprehensive evaluation will highlight any shortcomings that need to be addressed to bolster defenses against cyber threats.Following the assessment, establishing a robust cybersecurity governance program is essential. This framework must integrate IT and OT security, fostering a seamless defense mechanism that transcends various technology domains. A unified program not only closes the security gaps between IT and OT but also ensures that a harmonized security protocol is in place across the entire manufacturing environment. Additionally, such a program is instrumental in mounting a synchronized response to any cyber incidents, reinforcing the organization’s overall resilience to cyber attacks.Emphasizing the connection between IT and OT security as part of a holistic governance strategy is not just beneficial—it’s imperative. As manufacturing grows increasingly interconnected and reliant on digital infrastructure, cohesive cybersecurity governance that can adapt to new threats and protect all facets of the technological ecosystem becomes critical for the industry’s sustained success and the safeguarding of its assets.

Prioritizing Cybersecurity Actions

In addressing cybersecurity in manufacturing, prioritization is key. Once risks are identified, manufacturers must allocate their efforts to the most vulnerable areas first. Critical systems, especially those with direct external network access or those handling sensitive intellectual property (IP), should be the initial focus. This strategy ensures that limited resources are used effectively, emphasizing the protection of the most exposed aspects of the operation.The implementation of cybersecurity measures should not be an afterthought but an integral part of setting up a smart factory. By incorporating these precautions at the design and deployment stages, a foundational layer of security is established. This is essential to safeguard against the increasing number and sophistication of digital threats.As manufacturers evolve and their factories become more interconnected digitally, the potential entry points for cyber threats multiply. It is not just about defending the present infrastructure but also about anticipating the shifts in technology and cyber tactics. Continuous monitoring, regular updates, employee training, and response planning are critical to this adaptive security approach. Thus, cybersecurity in the smart manufacturing landscape becomes a dynamic, ongoing process that not only safeguards current operations but also prepares for future vulnerabilities, ensuring resilience in a digitalized industry.

Comprehensive Cyber Management Programs for the Future

Developing a Unified Governance Approach

In an era marked by sophisticated cyber threats, manufacturing firms must prioritize the establishment of a robust, integrated cyber management agenda. This strategic integration fuses Information Technology (IT) and Operational Technology (OT) security measures to form a cohesive defensive unit.At the heart of this strategy lies a solid governance framework. It mandates proactive tactics, cutting-edge threat detection that operates in real time, and swift incident response mechanisms. Additionally, the plan must include strong recovery protocols, equipping organizations with the resilience to bounce back promptly post-attack.Such an approach is not just about resisting cyber incursions but also about adapting and advancing the manufacturing sector’s immunity to digital threats. This calls for ongoing investments in security infrastructure and personnel training, ensuring that defenses evolve in lockstep with new and emerging threats.Regular security audits, employee education, and the adoption of best practices from both IT and OT fields fortify this unified security stance. By embracing a holistic cybersecurity posture, manufacturing entities can defend their assets, securing not only their technology and machinery but also the privacy and trust of their customers. It’s a comprehensive and agile blueprint for a safer, more secure manufacturing future.

Real-World Applications and Case Studies

Manufacturing businesses have increasingly recognized the importance of integrated IT-OT cybersecurity. Successful integration is achieved through both high-level planning and fostering a collaborative workplace culture, bolstered by cutting-edge tech solutions. These integration efforts not only protect against cyber threats but also enhance the company’s market standing, ensuring compliance, and delivering a competitive edge.Case studies highlight manufacturers that have taken a forward-thinking approach to cybersecurity. These companies use it as a shield to safeguard their operations and as a strategic tool that helps them navigate the digital landscape more securely and efficiently. The creation of smart factories, backed by a robust cybersecurity framework, is vital in this process. When factories are equipped to prevent and respond rapidly to cyber incidents, they’re more likely to enjoy uninterrupted innovation and growth.The proactive stance in cyber defense helps businesses avoid the fallout of security breaches, which can include financial loss, reputational damage, and operational downtime. By weaving cybersecurity into the fabric of their digital transformation, these organizations don’t just avoid risk—they also secure a foothold in a future where agility and safety in the digital domain are paramount for sustainable success.