Artificial Intelligence (AI) is making remarkable strides in numerous industries, particularly in engineering and manufacturing. The integration of advanced AI technologies such as accelerated computing, physics-informed AI, and generative AI is leading to faster, more sustainable, and unprecedentedly accurate innovations. These advancements are fundamentally transforming how modern engineering and manufacturing processes function, significantly reducing development times and enhancing the precision of final products. Companies and researchers alike are increasingly turning to AI to overcome traditional limitations and unlock new potential within various fields, laying the groundwork for a future driven by intelligent automation and enhanced productivity.

AI and Accelerated Computing in Engineering

AI and accelerated computing are significantly reshaping industries such as automotive, manufacturing, aerospace, and energy. These advancements enable independent software vendors to incorporate AI into their product offerings more effectively, recognizing its potential to optimize material layouts, enhance performance, and tackle physical constraints. Problems related to stress, strain, fatigue, and thermal limits are especially targeted. AI surrogate models for phenomena like thermal diffusion, fluid flow, and linear deformation provide real-time feedback on product performance, allowing designers to forecast critical physical figures-of-merit such as drag or surface pressure before engaging in high-fidelity simulations. This proactive approach drastically improves both the efficiency and effectiveness of design processes.

Simulation-based design processes are also witnessing a revolutionary change thanks to AI. Traditional simulation methods often require extensive computation time and may not be accurate enough for complex physical systems, but AI significantly accelerates these processes while ensuring enhanced simulation accuracy. Everything manufactured in today’s world undergoes an extensive simulation phase, and physics-informed neural networks (PINNs) are now playing a pivotal role. These networks enable simulations that are exponentially faster than conventional methods by incorporating the governing physics equations directly into the machine learning framework. This yields surrogate models that blend physics-based causality with simulation and observed data, delivering real-time predictions. Nvidia’s Modulus framework is one such example that includes PINN architectures suitable for external aerodynamics, fluid flow, and many other applications.

Generative AI and Design Optimization

AI tools have been instrumental in making substantial progress in terms of power requirements and thermal issues, which are crucial for chip manufacturers who prioritize power, performance, and area (PPA) metrics. Optimizing these metrics relies heavily on AI-enhanced tools such as Nvidia cuOpt. These tools deliver rapid solutions that account for physical constraints using CUDA-accelerated solvers based on heuristics and metaheuristics. By integrating generative AI and accelerated computing into the design process, designers can now evaluate a wider range of possibilities far more quickly than ever before, leading to superior, well-rounded designs that were previously impossible to achieve within short timeframes.

Real-world examples of physics-inspired AI successfully solving complex engineering tasks abound. Siemens Gamesa, for instance, employed Nvidia Modulus to train a PINN for wind turbine wake optimization, achieving an incredible 4,000x speedup over traditional methods. This not only enabled the creation of intricate, large-scale wind farm layouts but also maximized energy output. Similarly, Wistron developed digital twins for accurate prediction of airflow and temperature in test facilities. What used to take 15 hours is now completed in a mere three seconds with Nvidia GPUs, representing a 15,000x speedup. Siemens Energy also leveraged digital twins to optimize the uptime of heat recovery steam generators by predicting corrosion through high-fidelity simulations of multiphase turbulent flow. The result? A 70% reduction in unplanned downtime and astonishing industry-wide savings of $1.7 billion annually.

AI in Quantum Computing and Advanced Research

In cutting-edge research areas such as quantum computing, AI is essential for overcoming scaling challenges. AI contributes to the design of hybrid algorithms, the correction of quantum errors, the calibration of large systems without the need for exponentially increasing resources, and the generation of optimal control pulses to minimize noise. These areas are benefiting immensely from existing AI tools, although future iterations promise to enhance their capabilities even further. AI’s ability to address complex problems in this highly specialized domain signifies a major leap forward in research and practical applications alike.

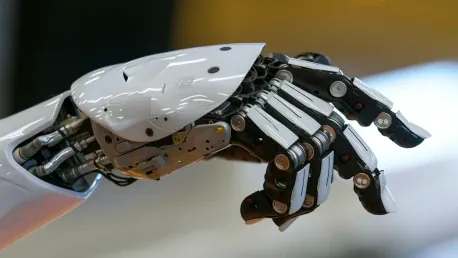

Future AI applications are set to span even more diverse fields, from advanced manufacturing to life sciences, space exploration, energy production, and the development of smart cities. Autonomous mobile robots, robotic arms, and humanoid robots in warehouses and factories present fascinating examples of complex systems requiring coordinated AI training for safety and optimization. Nvidia’s reference architecture, which combines accelerated computing, AI, Nvidia Isaac, and Nvidia Omniverse technologies, is being utilized to develop digital twins for AI-powered robotic systems. This comprehensive approach helps make facilities more efficient and adaptable, showcasing how AI can streamline and elevate multiple facets of modern industry.

AI-Driven Weather Prediction and Digital Biology

Artificial Intelligence (AI) is making significant advancements across various industries, especially in the fields of engineering and manufacturing. The adoption of cutting-edge AI technologies—such as accelerated computing, physics-informed AI, and generative AI—is driving these sectors to new heights. These innovations lead to faster, more sustainable, and astonishingly precise outcomes. As a result, modern engineering and manufacturing processes are undergoing a fundamental transformation. This transformation is characterized by shorter development cycles and a considerable improvement in the accuracy of final products.

Companies and researchers are increasingly relying on AI to break through traditional barriers, uncover new opportunities, and optimize different aspects of their work. By doing so, they are setting the stage for a future that is heavily influenced by intelligent automation and improved productivity. This reliance on AI is not just a trend but a significant shift that impacts how industries operate. The integration of AI brings about a multitude of benefits, ranging from cost savings to enhanced product quality, making it an indispensable tool in contemporary engineering and manufacturing. Through these advancements, AI is paving the way for unprecedented innovation and efficiency.