In the fast-evolving landscape of sustainable manufacturing, much attention is given to high-profile efforts like slashing carbon emissions, optimizing energy consumption, and transitioning to eco-friendly packaging solutions, but a less obvious yet equally powerful contributor often slips under the radar: labeling. This seemingly routine aspect of production holds untapped potential to drive significant environmental progress. Far from being just a means of compliance or product identification, labeling can play a pivotal role in reducing waste, enhancing operational efficiency, and supporting greener practices across the supply chain. As manufacturers strive to meet ambitious sustainability targets, rethinking labeling strategies could unlock unexpected benefits. This exploration delves into how innovative approaches to labeling are reshaping the industry’s approach to environmental responsibility, proving that even the smallest components of manufacturing can have a profound impact on the planet’s future.

Uncovering Labeling’s Role in Green Practices

In the broader context of sustainable manufacturing, labeling is frequently dismissed as a minor operational detail. However, it carries substantial weight when viewed through the lens of environmental impact. Missteps in labeling—such as errors in printing or outdated information—often result in considerable waste, from discarded products to disrupted shipments and costly rework. These inefficiencies drain resources and inflate a company’s ecological footprint. Addressing such challenges through smarter labeling practices can yield measurable gains, cutting down on unnecessary material use and streamlining processes. Industry insights, including a notable Morgan Stanley report showing that 88% of companies recognize sustainability as a key to long-term value, highlight the urgency of weaving labeling into broader green strategies. By tackling these often-overlooked inefficiencies, manufacturers can align with sustainability goals while maintaining a competitive edge in a market increasingly driven by environmental consciousness.

Beyond the immediate waste tied to labeling errors, there’s a deeper connection to systemic sustainability challenges. Inaccurate or poorly managed labels can ripple through the supply chain, causing delays, overproduction, and even regulatory penalties. These issues not only squander resources like paper and ink but also contribute to excess energy consumption during corrective actions. Modernizing labeling processes offers a chance to curb such losses, turning a mundane task into a strategic asset for environmental stewardship. The shift requires recognizing that every element of production, no matter how small, intersects with the larger goal of reducing impact on the planet. As manufacturers face mounting pressure to adopt sustainable practices, integrating improved labeling methods becomes not just an option, but a necessity for staying relevant. This perspective reframes labeling as a critical piece of the puzzle, capable of amplifying the effectiveness of other green initiatives when approached with intention and innovation.

Technology Driving Sustainable Labeling Solutions

Technology stands at the forefront of transforming labeling into a cornerstone of sustainable manufacturing. Print automation, for instance, integrates seamlessly with systems like ERP (Enterprise Resource Planning) and WMS (Warehouse Management Systems) to produce labels precisely when triggered by data updates. This eliminates human error, reduces misprints, and conserves vital resources such as paper, ink, and energy. Complementing this is on-demand printing, which ensures labels are created only as needed, preventing overproduction and allowing swift updates to comply with evolving eco-certifications or branding requirements. These advancements keep manufacturing nimble while slashing unnecessary waste, demonstrating that targeted technological interventions can produce outsized environmental benefits. By adopting such tools, companies can refine their operations, proving that precision in even the smallest processes can contribute significantly to overarching sustainability objectives.

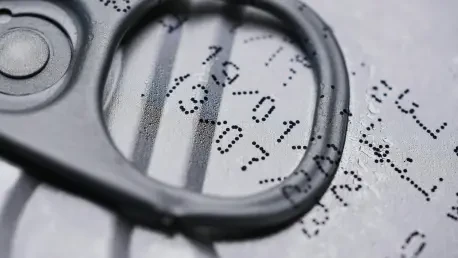

Another layer of innovation comes from dynamic label templates and 2D barcodes, which further bolster sustainability efforts. Dynamic templates automate data input by linking label fields to databases, ensuring that only accurate, up-to-date information is printed, thus minimizing errors and obsolete stock. Meanwhile, 2D barcodes, such as QR codes, condense vast amounts of information—from recycling guidelines to multilingual content—into a compact format. This reduces the need for expansive packaging materials while enhancing transparency, as stakeholders can access detailed product data with a simple scan. Operationally, these barcodes improve inventory tracking and cut down on logistical mistakes, a major source of waste in production cycles. Together, these technologies illustrate how digital solutions can address both material efficiency and informational clarity, offering manufacturers practical ways to align labeling with environmental goals without sacrificing functionality or speed.

Optimizing Operations for Environmental Gains

Centralized label management emerges as a powerful strategy for embedding sustainability into labeling workflows. By transitioning to cloud-based systems, manufacturers can eliminate redundant local software installations, reduce on-site hardware, and lower the energy demands associated with maintaining servers. This not only streamlines IT resources but also shrinks the carbon footprint of operations by cutting electricity use and heat generation. Such systems integrate advanced features like print automation and traceability, creating a unified framework that supports green objectives. The approach proves particularly valuable for companies looking to scale sustainable practices without undertaking massive systemic overhauls. By centralizing control over labeling processes, manufacturers can ensure consistency, reduce errors, and drive efficiency, all while contributing to a lighter environmental impact across their facilities.

The benefits of sustainable labeling extend far beyond factory walls, influencing the entire supply chain. Accurate labels and efficient barcodes diminish risks of overproduction and transportation errors, both of which are significant contributors to waste in manufacturing networks. Centralized systems also facilitate compliance with shifting sustainability standards, enabling companies to adapt swiftly to new regulations or market expectations. This interconnected impact underscores how labeling touches every stage of production, from raw material sourcing to final delivery. By prioritizing precision and innovation in this area, manufacturers can mitigate inefficiencies that ripple through logistics and distribution channels. The result is a more cohesive operation that not only meets environmental targets but also enhances reliability and trust among partners and consumers, reinforcing the value of integrating sustainable labeling into broader operational strategies.

Redefining Perspectives on Manufacturing Sustainability

The evolving landscape of manufacturing reveals a critical truth: sustainability is no longer a peripheral concern but a central pillar of business strategy. Labeling, often underestimated, is gaining recognition as a vital tool in this shift. Manufacturers must reframe their view, seeing labeling not as a mere formality but as an avenue for meaningful innovation. Embracing technologies like automation, on-demand printing, and centralized systems can amplify the impact of green initiatives, balancing profitability with planetary responsibility. This mindset change is essential as industries face growing scrutiny over their environmental practices. By focusing on labeling as a point of optimization, companies can uncover efficiencies that strengthen their commitment to sustainability while maintaining operational excellence, setting a precedent for how incremental changes can drive transformative outcomes.

Reflecting on past efforts, it becomes evident that small, strategic adjustments in labeling have already begun to yield substantial environmental benefits for many manufacturers. Looking ahead, the focus shifts to scaling these solutions, ensuring that technologies like 2D barcodes and cloud-based management systems are accessible to operations of all sizes. Industry leaders recognize the need to prioritize education and investment in these tools, fostering collaboration to address implementation challenges. The next steps involve integrating labeling innovations with emerging sustainability frameworks, creating a seamless alignment between daily processes and long-term ecological goals. By building on these foundations, the manufacturing sector positions itself to achieve deeper reductions in waste and resource use, paving the way for a future where even the smallest operational detail contributes to a healthier planet.