The food and beverage industry operates on a razor’s edge where success is often determined by an “invisible” engine of highly efficient inventory management, a critical function that remains unseen by the end consumer. Unlike other sectors that can absorb certain inefficiencies, businesses in this vertical face a unique and unforgiving combination of high-stakes challenges, including the constant threat of perishability, the burden of stringent regulations, and the absolute necessity for complex traceability. These factors transform modern, specialized inventory systems from a mere competitive advantage into a foundational requirement for both survival and scalable growth. In this demanding environment, the decision to invest in sophisticated inventory management is not just an operational upgrade; it is a strategic maneuver that converts a potential catastrophic liability into a powerful and enduring asset, setting the stage for long-term viability and success.

The Unforgiving Demands of the Sector

The core challenges inherent in food and beverage inventory management are both multifaceted and unforgiving, creating an operational landscape with virtually no margin for error. First and foremost is the immutable reality of perishability. Every item, from raw ingredients to finished consumer goods, is on a ticking clock, and short shelf lives demand precise, time-sensitive stock control to mitigate spoilage and prevent devastating financial losses. This pressure is significantly compounded by the weight of strict regulatory standards, such as the Hazard Analysis and Critical Control Points (HACCP) system, which imposes rigorous and non-negotiable compliance obligations. A failure to adhere to these standards does not simply impact the bottom line; it can trigger immensely costly product recalls, invite severe government intervention, and inflict irreparable damage on a brand’s reputation, eroding consumer trust that may have taken years to build. This intersection of time sensitivity and regulatory scrutiny makes rudimentary inventory practices untenable.

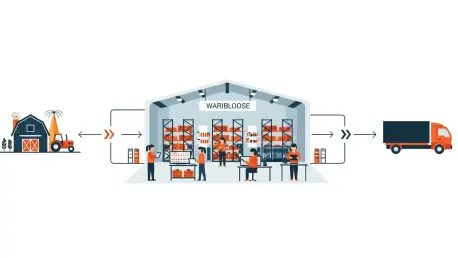

Beyond the immediate concerns of spoilage and compliance, the absolute necessity for robust, end-to-end traceability stands as a paramount operational requirement. Businesses must possess the unwavering ability to track a specific batch of a finished product all the way back through the supply chain to its constituent raw ingredients and their specific points of origin. This capability is far more than an internal quality control measure; it has become a non-negotiable prerequisite for securing and maintaining contracts with large distributors, supermarket chains, and other major retailers that demand complete supply chain transparency. Attempting to manage this intricate and voluminous web of data with manual methods, such as spreadsheets or paper logs, is not only staggeringly inefficient but also dangerously prone to human error. Such outdated practices expose the entire operation to significant risk, undermining a company’s ability to respond swiftly and accurately in the event of a quality issue or recall.

The Compounding Costs of Inaction

The inherent challenges of food and beverage inventory management are further exacerbated and amplified by contemporary commercial pressures that leave little room for operational laxity. In an economic environment characterized by tighter profit margins and heightened consumer price sensitivity, the need for accurate cost management and precise financial forecasting has become more critical than ever. To remain competitive and profitable, businesses require clear, real-time visibility into every facet of their operations. This includes the ability to understand the precise profitability of each individual product line or stock-keeping unit (SKU), effectively manage complex and often rigid vendor ordering requirements, and make agile, data-driven strategic decisions. Outdated or manual inventory systems are fundamentally incapable of providing this requisite level of granular insight, rendering them obsolete in the modern marketplace and a significant drag on a company’s potential.

These legacy systems rapidly evolve from minor inconveniences into significant liabilities, breeding a culture of inefficiency that permeates the entire organization and stifles growth. Staff members are forced to spend countless hours on tedious, low-value tasks like manually reconciling data across disparate spreadsheets, leading to lost productivity and increased labor costs. Furthermore, production tracking becomes unreliable, and a lack of real-time visibility across the supply chain leads to poor decision-making, stockouts, or excess inventory. Many businesses unfortunately wait until they reach a “breaking point”—a moment where their outdated systems completely fail to keep pace with operational demands—before seeking a modern solution. This reactive approach invariably makes the transition far more difficult, disruptive, and costly, as it necessitates not only a technological overhaul but also a significant change management effort to correct deeply ingrained, inefficient processes that have become standard practice.

A Blueprint for Success in Practice

The profound impact of a successful transition from a legacy system to a modern, integrated solution is powerfully illustrated by the case of Lick Ice Cream, a family-owned Australian gourmet ice cream company. The business found itself grappling with a confluence of complexities that are typical of a growing enterprise in the food and beverage industry. Its operations included a diverse and demanding distribution network that spanned from its own retail stores to large, national supermarket chains. The manufacturing process was intricate, involving numerous raw ingredients, each with its own strict quality controls and shelf life. Adherence to rigorous HACCP standards was non-negotiable, and a wide portfolio of distinct flavors required granular margin analysis to ensure profitability. The company’s existing systems were struggling to manage this intricate mix of operations, creating bottlenecks and limiting its ability to scale effectively and confidently.

The implementation of specialized inventory management software provided a comprehensive, end-to-end solution that systematically integrated every stage of the company’s workflow, transforming its operational capabilities. The new system delivered complete, real-time visibility, from the moment raw materials were received to the final shipment of finished products to customers. It streamlined the creation of manufacturing orders, automated the critical tracking of batch numbers to ensure full traceability, and generated accurate picking lists for warehouse staff, minimizing errors and improving efficiency. The most significant outcomes were a newfound confidence in their data, the ability to conduct precise margin analysis on every product, and the establishment of a robust, auditable system for compliance. This transformation gave the team what its CEO described as “full control” over its inventory, significantly reducing waste, ensuring accuracy, and strategically positioning the company for ambitious future growth, including expansion into export markets.

A Strategic Foundation for the Future

The central lesson that emerged was that the adoption of a specialized inventory management system represented far more than a simple operational upgrade; it was a foundational strategic imperative for survival and growth in the demanding food and beverage industry. The narrative cohesively argued that the question was not if a business would eventually need such a system, but when the breaking point would be reached. A proactive approach was strongly advised, with businesses urged to adopt scalable systems early in their growth journey. The first step for any company considering such a change involved deeply understanding its own growth model to select a platform that could support its needs not just for the present, but for many years into the future. It became clear that the technology itself was only one part of a much larger equation. The true differentiator was found in the service, training, and long-term partnership that helped a business fully integrate the new system and optimize its internal processes, ensuring that the people using the technology were empowered by it. This holistic approach proved crucial for the long-term success of the implementation, making a strategic investment in modern inventory management an indispensable foundation.