In an era where technological innovation and industrial transformation are reshaping the American landscape, the demand for magnetic testing equipment is emerging as a critical component of progress, with projections indicating substantial growth by 2035. This specialized equipment, essential for validating the performance and reliability of magnetic materials, is becoming indispensable across a range of sectors, from automotive electrification to renewable energy systems. As industries strive for precision and sustainability, the market for these tools is not just expanding but also evolving, driven by the urgent need to meet stringent quality standards and regulatory requirements. The significance of this trend cannot be overstated, as it reflects a broader shift toward advanced manufacturing and clean energy solutions that are redefining how products are designed and built.

The market’s trajectory over the next decade offers a compelling narrative of opportunity and challenge, with a forecasted increase in value that underscores its growing importance. Stakeholders across various industries are recognizing the pivotal role that magnetic testing equipment plays in ensuring material integrity, particularly in high-stakes applications like electric vehicle (EV) components and renewable energy generators. This surge in demand is fueled by a convergence of factors, including technological advancements, regional industrial strengths, and supportive government policies. As the USA positions itself as a leader in sustainable innovation, understanding the dynamics of this niche yet vital market becomes essential for manufacturers, policymakers, and investors aiming to capitalize on emerging trends.

Market Growth and Key Drivers

Projected Expansion and Economic Impact

The market for magnetic testing equipment in the USA is on a robust growth path, with its value expected to rise from USD 28.6 million currently to USD 41.8 million by 2035, achieving a steady compound annual growth rate (CAGR) of 3.7%. This expansion is anticipated to unfold in two distinct phases over the decade, with significant increases in both the early and later years, reflecting sustained demand across multiple sectors. The economic implications of this growth are far-reaching, as it promises to drive innovation in manufacturing processes while creating new job opportunities in specialized fields. Beyond the numbers, this trend highlights a growing reliance on advanced testing solutions to support the production of cutting-edge technologies, positioning the market as a cornerstone of industrial progress in the country.

Moreover, the ripple effects of this market expansion are expected to influence supply chains and investment strategies nationwide. As industries increasingly adopt magnetic testing equipment to ensure product quality, there will likely be a surge in demand for skilled technicians and engineers trained to operate and maintain these sophisticated systems. This, in turn, could stimulate educational programs and vocational training focused on industrial technology, further embedding the importance of this equipment in the broader economic fabric. The consistent growth trajectory also signals to investors that this sector offers stable returns, encouraging capital inflow into research and development to push the boundaries of what testing equipment can achieve.

Primary Forces Fueling Demand

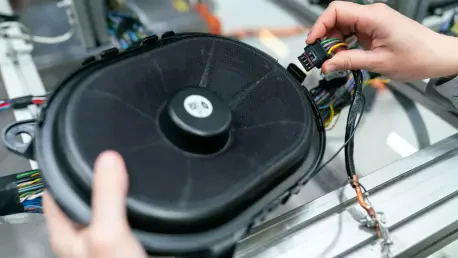

A primary catalyst behind the escalating demand for magnetic testing equipment is the rapid advancement of automotive electrification, particularly with the proliferation of electric vehicles (EVs) that rely heavily on magnetic materials for powertrains and battery systems. These components must undergo rigorous testing to meet strict performance and safety standards, making advanced equipment indispensable for manufacturers aiming to stay competitive in a fast-evolving market. The push toward zero-emission transportation, supported by federal and state initiatives, amplifies this need, as more companies pivot to EV production, driving a consistent uptick in the requirement for reliable testing solutions that ensure compliance and efficiency.

Another significant force propelling this market is the growing adoption of renewable energy systems, such as wind turbines and solar power installations, which depend on permanent magnets for optimal operation. These magnets must be tested for durability and performance under harsh environmental conditions, a process that necessitates cutting-edge magnetization and testing tools. As the USA intensifies its commitment to clean energy goals, the demand for equipment capable of validating these critical components is expected to soar. Additionally, the emphasis on precision manufacturing across various industries further fuels the need for sophisticated systems, as quality control becomes a non-negotiable aspect of production, supported by policies that incentivize excellence and sustainability in industrial practices.

Technological Advancements and Industry Applications

Innovations Shaping the Future

The landscape of magnetic testing equipment is being transformed by groundbreaking technological advancements, with automation and high-field magnetization systems leading the charge in enhancing operational efficiency and accuracy. Automated testing solutions, integrated with real-time data monitoring, are enabling manufacturers to streamline processes, reduce human error, and achieve consistent results across large-scale production runs. These innovations are particularly crucial in industries where precision is paramount, as they allow for rapid detection of material flaws and ensure that magnetic components meet exacting standards. The adoption of such technologies is not merely a trend but a fundamental shift in how testing is conducted, setting a new benchmark for reliability in industrial applications.

Furthermore, the development of high-field magnetization tools represents a leap forward in addressing the complex needs of modern manufacturing. These systems are designed to handle advanced applications that require exceptional performance, such as testing materials used in high-efficiency motors and energy storage solutions. By offering greater control and precision, these tools are helping manufacturers push the boundaries of what is possible, catering to niche demands in sectors that are at the forefront of innovation. The integration of such cutting-edge technologies into existing production frameworks, while challenging, is proving to be a game-changer, as it enhances productivity and positions companies to meet the evolving expectations of regulators and consumers alike.

Sector-Specific Demand Patterns

The automotive sector stands out as a dominant force in driving demand for magnetic testing equipment, holding a substantial market share due to the critical role of magnetic materials in EV production and battery validation. As manufacturers scale up efforts to meet the rising consumer demand for electric vehicles, the need for precise testing of components like powertrains becomes increasingly vital to ensure safety, efficiency, and compliance with stringent regulations. This reliance on advanced equipment is evident in the rigorous quality assurance protocols adopted by leading automakers, which prioritize the integrity of magnetic materials to maintain a competitive edge in a market that is rapidly shifting toward sustainable transportation solutions.

In parallel, the renewable energy sector is emerging as a significant contributor to the demand for testing equipment, with applications in wind turbines and solar energy systems gaining prominence. Permanent magnets used in generators and storage units must withstand extreme conditions, necessitating thorough testing to guarantee long-term reliability and performance. This growing focus on clean energy, backed by governmental support for sustainability, is creating a steady stream of opportunities for equipment providers to cater to specialized needs. Additionally, other industries, such as consumer electronics, are beginning to explore the benefits of magnetic testing, broadening the market’s scope and signaling untapped potential for growth across diverse applications beyond traditional strongholds.

Regional Dynamics and Competitive Landscape

Geographic Variations in Growth

Demand for magnetic testing equipment across the USA exhibits notable regional variations, with the West leading the charge at a 4.1% CAGR, largely due to its concentration of technology hubs and a culture of early adoption of premium systems. States like California, known for innovation-driven economies, are at the forefront of integrating advanced testing solutions into manufacturing processes, fueled by a strong emphasis on research and development. This regional strength not only drives market growth but also sets a precedent for other areas to follow, as the adoption of cutting-edge technologies in the West often influences broader national trends, positioning it as a pacesetter in the industry.

Meanwhile, the Midwest, with a CAGR of 3.8%, benefits from a deeply rooted automotive manufacturing base, particularly in states like Michigan and Ohio, where the demand for testing equipment is tied to large-scale EV production. The South, growing at 3.6%, reflects a region in transition, with expanding industrial facilities driving equipment uptake, while the Northeast, at a 3.4% CAGR, leverages its established technological infrastructure for steady progress. These geographic differences highlight the diverse industrial compositions and policy environments shaping market dynamics, offering unique opportunities for targeted strategies that address specific regional needs and capitalize on local strengths to maximize impact.

Key Players and Market Strategies

The competitive landscape for magnetic testing equipment is marked by intense rivalry among key players like Magnet-Physik, which commands a 22% market share, alongside notable contenders such as Laboratorio Elettrofisico and HORIBA. These companies are distinguishing themselves through a relentless focus on innovation, developing advanced solutions that cater to the precise needs of industries like automotive and renewable energy. Their ability to stay ahead of technological curves, coupled with robust distribution networks, allows them to maintain a strong foothold in a market that demands both quality and reliability, setting a high standard for others to emulate.

Beyond technological prowess, strategic partnerships and customer-centric approaches are becoming critical differentiators in this space. Leading firms are investing in supply chain optimization to ensure timely delivery of equipment and are offering tailored solutions that address specific industry challenges, fostering long-term relationships with clients. Additionally, comprehensive service offerings, including maintenance and training, are enhancing their value proposition, as end-users increasingly seek partners who can support the entire lifecycle of their equipment. This emphasis on adaptability and engagement underscores a competitive environment where success hinges on more than just product excellence, shaping how companies position themselves for sustained growth.

Opportunities and Challenges Ahead

Pathways for Future Growth

The market for magnetic testing equipment presents a wealth of opportunity pathways, with potential revenues ranging from USD 2.4 million to USD 8.4 million across various segments by 2035. Targeting EV manufacturing stands out as a particularly lucrative avenue, given the sector’s dominant role in driving demand for precise testing of magnetic components essential to vehicle performance. Similarly, renewable energy systems offer substantial growth potential, as the need for reliable permanent magnets in wind and solar applications continues to rise. These pathways provide a clear roadmap for stakeholders to align their strategies with emerging industry needs, ensuring they capture a significant share of the expanding market.

Additionally, opportunities in automated testing integration and high-field magnetization solutions are gaining traction, reflecting a shift toward specialization and efficiency in industrial processes. Automated systems, with potential revenues up to USD 5.1 million, promise to streamline operations and reduce costs, while high-field tools cater to advanced applications with revenues projected up to USD 6.3 million. Service networks, offering ongoing support and maintenance, also represent a steady income stream with potential earnings up to USD 3.8 million. By focusing on these diverse avenues, manufacturers and suppliers can address niche demands, tailoring their offerings to specific sectors and positioning themselves as indispensable partners in the journey toward technological and industrial advancement.

Barriers and Solutions

Despite the optimistic outlook, the market faces significant challenges, notably the complexity and cost of integrating new magnetic testing systems into existing manufacturing infrastructures. Smaller manufacturers, in particular, may find the upfront investment and technical expertise required to adopt advanced equipment prohibitive, potentially slowing market penetration in certain segments. This barrier is compounded by the need for extensive training to operate sophisticated tools, which can strain resources and delay implementation. Addressing these integration hurdles is crucial to ensuring that the benefits of cutting-edge technology are accessible across the industry spectrum, preventing a widening gap between large and small players.

To mitigate these challenges, collaborative models between equipment manufacturers and technology providers are proving effective, particularly in regions with strong industrial clusters like the Midwest and West. Such partnerships facilitate knowledge transfer and economies of scale, reducing costs and easing the transition to new systems. Additionally, leveraging federal and state incentives for adopting advanced manufacturing technologies can offset financial burdens, encouraging wider uptake. By focusing on scalable solutions and fostering alliances, the industry can overcome these obstacles, ensuring that even smaller firms can harness the power of magnetic testing equipment to enhance their operations and remain competitive in a rapidly evolving market.

Shaping a Sustainable Industrial Future

Looking back over the insights discussed, the journey of magnetic testing equipment in the USA from the current year to 2035 reveals a compelling story of growth and adaptation, marked by a projected rise to a market value of USD 41.8 million at a steady CAGR of 3.7%. The transformative influence of automotive electrification and renewable energy adoption stands as central pillars that fuel demand, while regional variations and intense competition among key players add layers of complexity to the narrative. Technological innovations, from automation to high-field systems, emerge as vital tools that reshape how industries approach quality assurance and performance validation in critical applications.

Moving forward, stakeholders must prioritize strategic investments in opportunity pathways like EV manufacturing and automated testing integration to harness the full potential of this expanding market. Building robust partnerships and leveraging policy support will be essential steps to address integration challenges and ensure broader accessibility of advanced equipment. Emphasizing specialization and customer engagement can further solidify market positions, while continuous adaptation to regulatory and technological shifts will safeguard long-term relevance. As industries align with sustainability goals, the focus on magnetic testing equipment must intensify, driving innovation and collaboration to support a future where precision and environmental responsibility go hand in hand.