As artificial intelligence (AI) continues to redefine the boundaries of technology, the semiconductor industry, which serves as the critical foundation for these advancements, faces an unprecedented challenge in meeting soaring computational demands while grappling with a significant environmental footprint. The production of chips that power AI systems consumes immense amounts of energy and resources, often rivaling the usage of entire small cities. Historically, the focus in this sector has been on performance and cost efficiency, with sustainability often taking a backseat. However, a seismic shift is underway, driven by escalating environmental concerns, regulatory pressures, and the sheer necessity of aligning innovation with planetary health. This transformation is not just a response to external forces but a strategic move to ensure long-term viability in a competitive landscape where green practices are becoming a defining factor. The stakes couldn’t be higher—balancing the insatiable hunger for AI capabilities with the urgent need to reduce carbon emissions and resource waste is shaping the future of technology itself. From major corporations to agile startups, the industry is mobilizing to address these issues through innovative manufacturing, collaborative efforts, and a reimagined approach to what it means to power progress responsibly.

Pioneering Eco-Friendly Practices in Chip Production

Cutting Emissions: A Strategic Imperative

The semiconductor industry is placing a sharp focus on reducing greenhouse gas emissions across all operational scopes, from direct outputs to indirect energy use and the sprawling impacts of supply chains. Leading companies like TSMC and Intel have set ambitious net-zero targets for the coming decades, with renewable energy adoption already reaching impressive levels in their global operations. The urgency of this mission is evident in collaborative platforms like the Semiconductor Climate Consortium (SCC), which is working to standardize emissions data collection, particularly for the elusive Scope 3 emissions tied to supply chains. A specific target includes addressing high-impact gases like perfluorocarbons, which carry a global warming potential far exceeding carbon dioxide. This comprehensive approach signals a profound commitment to not only curb immediate environmental harm but also to set a precedent for sustainable industrial practices that ripple through the tech ecosystem.

Beyond corporate pledges, the push to slash emissions is reshaping operational priorities in tangible ways. Factories are transitioning to renewable energy sources at an accelerated pace, significantly cutting down on indirect emissions tied to power consumption. This shift is complemented by innovations in process technologies that minimize the release of harmful gases during manufacturing. The emphasis on supply chain accountability is also gaining traction, as companies pressure upstream and downstream partners to adopt greener practices. While challenges remain—especially in tracking and mitigating indirect emissions—the momentum is clear. The industry recognizes that reducing its carbon footprint is not just an ethical obligation but a critical component of maintaining market relevance in an era where environmental performance is scrutinized as closely as technological prowess.

Optimizing Resources: Efficiency at the Core

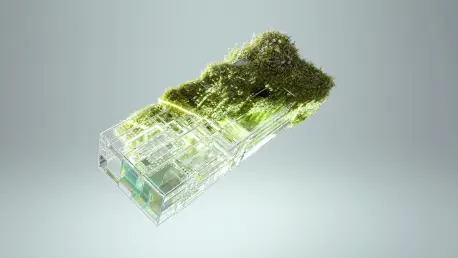

Semiconductor fabrication is notoriously resource-intensive, demanding vast quantities of electricity and ultrapure water to produce the chips that fuel AI systems. Some manufacturing facilities consume as much power as small urban centers, highlighting the scale of the environmental challenge. To combat this, groundbreaking initiatives like TSMC’s EUV Dynamic Energy Saving Program are being rolled out, targeting substantial reductions in peak power usage by the end of this decade. These advancements promise not only to lower energy bills but also to significantly decrease carbon emissions associated with production. Such efforts reflect a broader industry trend toward reengineering processes to prioritize efficiency without compromising the high standards required for cutting-edge chip performance.

Water usage, another critical concern, is also under intense scrutiny as manufacturers strive to balance stringent purity requirements with sustainable practices. Recycling technologies are advancing, with incremental progress in reclaiming water despite the complex challenges posed by contamination risks. These steps, though still evolving, point to a future where resource optimization is embedded in the fabric of semiconductor production. The drive to minimize waste extends beyond immediate factory outputs, encouraging a holistic view of resource lifecycles. By addressing the colossal environmental footprint of fabrication plants, the industry is not merely reacting to criticism but proactively forging a path where sustainable manufacturing becomes a benchmark for success in powering AI technologies.

AI’s Dual Impact on Environmental Progress

Energy Demands vs. Innovative Solutions

AI’s rapid expansion presents a paradox for the semiconductor industry, as the technology driving revolutionary change also places immense strain on environmental resources. Training large AI models and operating data centers require staggering amounts of energy, often sourced from non-renewable means, while the production of specialized hardware adds further pressure on water and power supplies. This reality has pushed the industry to confront the harsh environmental costs of intelligence, with factories and tech hubs becoming focal points for criticism over their outsized consumption. Metrics like Google’s Compute Carbon Intensity (CCI) are emerging as vital tools to quantify and address these impacts, offering a framework to measure emissions per computational unit and guide reductions in hardware’s ecological burden.

Yet, within this challenge lies a remarkable opportunity, as AI itself is becoming a powerful ally in the quest for sustainability. Advanced algorithms are optimizing chip design and manufacturing processes, identifying inefficiencies, and reducing resource waste through predictive maintenance and smarter production workflows. These AI-driven solutions are not just mitigating the technology’s own footprint but are enhancing overall operational efficiency in semiconductor plants. The duality of AI as both a resource hog and a problem-solver underscores a nuanced dynamic where the very systems demanding more from the planet are also equipping the industry with tools to give back. This balance is pivotal, as it suggests a future where technological growth and environmental stewardship are not mutually exclusive but deeply interconnected.

Expanding AI’s Role in Wider Sustainability Efforts

The influence of AI on sustainability extends far beyond the confines of semiconductor manufacturing, reaching into broader environmental applications that could redefine energy management across sectors. AI systems are being leveraged to optimize power grids, ensuring more efficient distribution and reducing reliance on fossil fuels. In data centers, which are notorious for high energy consumption, AI-driven cooling and workload management are slashing electricity use, setting new standards for operational sustainability. These applications demonstrate how the technology can pivot from being a burden to a catalyst for systemic change, addressing global challenges that intersect with the semiconductor industry’s goals.

Moreover, AI is aiding in the design of more energy-efficient chips, which in turn support greener hardware ecosystems for everything from consumer devices to industrial systems. This ripple effect highlights the potential for AI to act as a force multiplier in environmental initiatives, amplifying the impact of sustainable practices initiated at the manufacturing level. As these technologies mature, their integration into climate modeling and renewable energy forecasting offers even greater promise for tackling pressing planetary issues. The symbiotic relationship between AI and sustainability is thus poised to grow, positioning the semiconductor industry at the forefront of a movement where innovation serves not just human progress but the health of the environment as a whole.

Market Shifts and Competitive Advantages

Green Credentials as a Business Lever

In the fast-evolving semiconductor landscape, sustainability has emerged as a decisive factor in determining market leaders and laggards. Tech giants with stringent net-zero commitments are increasingly selective, forging partnerships with manufacturers like TSMC and Samsung that demonstrate robust eco-friendly practices. This trend is reshaping supply chains, as companies without green credentials risk losing critical contracts and market share. The competitive edge gained through sustainable manufacturing is no longer a niche advantage but a core driver of business success, influencing everything from investor confidence to customer loyalty in a sector where environmental accountability is under intense public and regulatory scrutiny.

This shift is also fostering a new wave of innovation among established players and newcomers alike. Startups, bolstered by programs like Startups for Sustainable Semiconductors (S3), are carving out space by focusing on energy-efficient designs and novel materials that reduce environmental impact. These emerging companies are not just filling gaps but challenging larger corporations to accelerate their green transitions. The market dynamics are clear—sustainability is a differentiator that can make or break a company’s standing. As demand for AI hardware grows, the ability to deliver cutting-edge technology with a minimal ecological footprint is becoming a benchmark, pushing the entire industry toward a future where green practices are synonymous with competitive strength.

Regulatory Push and Global Implications

Government intervention is playing a pivotal role in steering the semiconductor industry toward sustainable practices, with policies designed to align technological advancement with environmental goals. The U.S. CHIPS and Science Act, for instance, incentivizes domestic production while embedding strict sustainability criteria, aiming to reduce reliance on overseas supply chains that often lack transparency in emissions reporting. Similarly, Europe’s Ecodesign for Sustainable Products Regulation sets rigorous standards for energy efficiency and material use, compelling manufacturers to rethink their processes. These legislative frameworks are not just enforcing compliance but fostering resilience by encouraging localized, eco-conscious production models.

The global implications of such policies are profound, as they reshape trade flows and supply chain strategies on an international scale. By prioritizing sustainability, these regulations are mitigating risks associated with geopolitical tensions and resource scarcity, ensuring that the industry can withstand future disruptions. Additionally, they are leveling the playing field by holding multinational corporations accountable to consistent environmental standards, regardless of where they operate. This harmonization of green expectations is driving a cultural shift within the sector, where compliance with sustainability mandates is seen as a stepping stone to innovation rather than a burden. The result is a more interconnected and responsible global market, where the pursuit of AI excellence is increasingly aligned with planetary well-being.

Ethical Challenges and Future Pathways

Navigating the Carbon Cost of Intelligence

The ethical implications of AI’s growth are coming under sharp focus as the semiconductor industry grapples with the substantial “carbon cost” of developing and deploying intelligent systems. The energy required to train sophisticated models and produce specialized hardware is immense, raising pressing questions about the moral responsibility of unchecked technological expansion. Industry stakeholders are being pushed to prioritize greener solutions, ensuring that advancements in AI do not exacerbate climate issues. This scrutiny extends to avoiding superficial sustainability claims, often termed greenwashing, which can undermine genuine efforts. Transparent, standardized reporting mechanisms are essential to validate progress, providing a clear picture of environmental impact that stakeholders can trust.

This ethical debate is not just academic but deeply practical, influencing how companies position themselves in the public eye and within regulatory frameworks. The pressure to mitigate AI’s environmental toll is driving innovations in low-power hardware and more efficient training algorithms, reflecting a commitment to balance progress with responsibility. However, the road ahead requires vigilance to ensure that short-term gains do not overshadow long-term sustainability goals. Independent verification of environmental claims is becoming a cornerstone of accountability, as the industry seeks to build trust with consumers and policymakers alike. Addressing these ethical dimensions is critical to shaping an AI-driven future that aligns with societal values and planetary limits.

Overcoming Hurdles to Lasting Change

Implementing sustainable infrastructure in the semiconductor industry comes with significant financial barriers, particularly for smaller firms that lack the capital of industry giants. The high upfront costs of transitioning to renewable energy or adopting advanced recycling systems can create disparities, potentially widening the gap between large corporations and emerging players. This economic challenge risks slowing the industry-wide adoption of green practices, as not all companies can absorb the initial investment required for long-term environmental benefits. Bridging this divide will require targeted support, whether through government incentives or collaborative industry funds, to ensure that sustainability is accessible across the board.

Another pressing issue is the growing problem of electronic waste, fueled by the rapid obsolescence of AI hardware in a field where newer, faster chips are constantly in demand. Developing scalable recycling solutions remains a frontier that the industry is only beginning to tackle, with current efforts falling short of the volume needed to manage discarded components effectively. Nevertheless, the concept of “design for sustainability” is gaining traction, encouraging engineers to factor environmental impact into chip architecture from the outset. This forward-thinking approach, combined with ongoing efforts to address cost barriers and waste management, offers a roadmap for systemic change. As these hurdles are navigated, the industry stands poised to redefine innovation, ensuring that the power of AI is harnessed without compromising the health of the planet for future generations.