The importance of sustainability in the medical packaging sector has surged in recent years due to the significant environmental impact of healthcare plastics. As the demand for more eco-friendly solutions rises, packaging manufacturers are compelled to optimize their sustainability efforts by improving packaging design, selecting materials more judiciously, and minimizing waste. One highly effective strategy that has emerged to drive these changes is simulation testing, particularly in silico modeling. This technology allows packaging engineers to electronically evaluate various designs, paving the way for faster iterations and optimization. The result is the development of more sustainable packaging solutions that reduce waste and conserve resources, addressing pressing environmental concerns while maintaining high standards of safety and functionality.

The Role of Simulation in Design Optimization

Advanced simulation technologies play a pivotal role in the sustainability of medical packaging by enabling engineers to perform detailed analyses of different packaging designs without the need for extensive physical prototyping. By conducting digital evaluations, engineers can assess multiple variables like material thickness, form factor, and failure points. This detailed scrutiny helps in identifying opportunities for lightweighting and material reduction, which are critical for sustainable design. The virtual approach also facilitates the exploration of alternative materials and configurations, offering insights that can further enhance sustainability. This digital methodology not only speeds up the development process but also leads to more informed decisions that can significantly reduce the environmental footprint of medical packaging.One of the prominent applications of simulation testing is in optimizing thermoformed plastics—a common material in medical packaging. Through digital modeling and virtual evaluations, stakeholders can assess the viability of various sustainable solutions before moving to physical production. This preemptive approach minimizes resource consumption and waste, ensuring that only the most feasible designs move forward. Additionally, scenario testing and sensitivity analysis allow manufacturers to anticipate and address potential issues long before they occur. By simulating real-world conditions and stressors, companies can ensure optimum performance and durability in their packaging solutions, thereby enhancing sustainability without compromising on customer satisfaction.

Lifecycle Implications and Real-world Applications

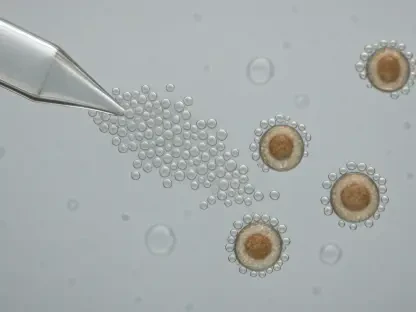

The benefits of simulation-based optimization extend beyond the design phase, spanning the entire lifecycle of medical device packaging—from transportation and storage to end-of-life scenarios. By optimizing package dimensions and configurations, manufacturers can find more opportunities for waste reduction and improve environmental stewardship. This holistic approach not only minimizes the storage space required for these packages but also reduces transportation emissions, as more efficient packaging leads to better space utilization in logistics. Optimal design aided by simulation tools ensures that the packaging is not only sustainable but also practical, meeting the functional needs of healthcare providers.Moreover, simulating the various stages of a package’s lifecycle can facilitate recycling and disposal processes. Manufacturers can design packages that are easier to dismantle, sort, and recycle, thereby reducing the burden on waste management systems. Additionally, by understanding the material interactions and potential degradation points through simulation, companies can enhance the recyclability of their products. This comprehensive understanding leads to the development of packaging solutions that are not only efficient in their primary use but also contribute to a circular economy by facilitating better end-of-life management.

Conclusion: A Paradigm Shift Toward Sustainability

Simulation-based optimization offers advantages that go beyond the initial design phase, impacting the entire lifecycle of medical device packaging—from transportation and storage to end-of-life scenarios. By refining package dimensions and configurations, manufacturers can unearth opportunities for waste reduction and enhance environmental responsibility. This comprehensive method not only decreases the storage space needed but also cuts down transportation emissions, thanks to more efficient packaging that maximizes space in logistics. Simulation tools help ensure that the packaging remains sustainable and practical, meeting healthcare providers’ needs.Additionally, simulating different lifecycle stages aids in recycling and disposal processes. Companies can design packages that are simpler to dismantle, sort, and recycle, easing the load on waste management systems. By understanding material interactions and potential degradation points via simulation, manufacturers can improve their products’ recyclability. This deep insight leads to packaging solutions efficient in primary use and supports a circular economy by improving end-of-life management.