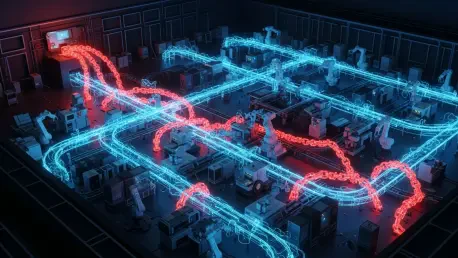

The intricate web of the global supply chain, a marvel of modern logistics and interconnectedness, is proving to be a critical vulnerability as threat actors increasingly set their sights on the manufacturing sector. Once considered a secondary target, manufacturing has rapidly ascended to the top of the ransomware hit list. The industry’s deep reliance on operational technology (OT) that is woven into the very fabric of production and distribution creates a high-stakes environment where any disruption can trigger a catastrophic cascade of failures. For cybercriminals, this dependency translates into immense leverage, as a single successful attack can halt production lines, cripple distribution networks, and bring a company to its knees, making the payment of a ransom seem like the only path to survival. The financial pressure is often so immediate and overwhelming that it outweighs the long-term consequences, turning manufacturers into prime, and often willing, payers in the ransomware economy. This reality has forced a paradigm shift in how the industry views cybersecurity, moving it from a back-office IT concern to a critical component of business continuity and risk management.

The Anatomy of Vulnerability

Operational Technology as a Double-Edged Sword

The very systems that drive efficiency and innovation in modern manufacturing are also its greatest weakness. Operational Technology, the complex network of hardware and software that monitors and controls physical processes, from robotic assembly lines to chemical processing, is deeply integrated into every facet of production. This interconnectedness means a compromise in one area can have an immediate and devastating domino effect across the entire operation. Unlike a typical IT breach where data might be stolen, an OT attack can cause tangible, physical disruption, leading to costly production stoppages, damaged equipment, and significant safety risks. The financial implications are staggering; every moment of downtime represents lost revenue and potential contractual penalties. This immense pressure creates a fertile ground for extortion. Cybercriminals understand that for a manufacturer, the cost of a ransom, while significant, may pale in comparison to the catastrophic losses incurred from a prolonged shutdown, making them highly motivated to pay quickly to restore operations and mitigate supply chain failures.

The Cybersecurity Resource Gap

A significant number of manufacturing companies are grappling with a perilous cybersecurity resource gap, making them soft targets for opportunistic attackers. Many facilities operate with outdated software and legacy systems that are riddled with unpatched vulnerabilities, often because updating them would require cost-prohibitive downtime. Furthermore, the industry frequently suffers from a lack of specialized cybersecurity expertise equipped to handle the unique challenges of securing complex OT environments. The prohibitive cost and intensive labor required to implement and maintain comprehensive security controls across vast and intricate operational infrastructures are often seen as an insurmountable barrier. This leads to a patchwork of limited security measures that leave critical systems exposed. For cybercriminals, this environment is ideal; it offers a target-rich landscape with a low barrier to entry and a high probability of a successful breach, allowing them to exploit known weaknesses with relative ease and minimal resistance from unprepared organizations.

The Evolving Threat Landscape

From Encryption to Exfiltration

The tactics employed by ransomware groups have undergone a dangerous evolution, shifting from a singular focus on data encryption to a more insidious model centered on data exfiltration. In the past, the primary threat was the locking of critical files, with a decryption key offered in exchange for a ransom. While disruptive, this could often be mitigated with robust data backup and recovery plans. However, modern attackers have recognized that the data itself is a far more valuable asset. Now, a common approach involves quietly infiltrating a network and stealing massive volumes of sensitive information—such as intellectual property, trade secrets, employee records, and client data—before ever deploying the ransomware. This stolen information becomes a powerful bargaining chip. The threat is no longer just about business interruption; it’s about the potential for corporate espionage, regulatory fines, and catastrophic reputational damage if the exfiltrated data is sold to competitors or released publicly.

The Rise of Double Extortion

This strategic shift to data theft has given rise to the highly effective tactic of “double extortion,” a two-pronged attack that dramatically increases the pressure on victims. In this scenario, cybercriminals demand a ransom not only to provide a key to decrypt the company’s encrypted files but also to promise the deletion of the sensitive data they have already stolen. This dual threat forces executives into an incredibly difficult position. Even if a company has reliable backups and can restore its systems without paying for a decryption key, it still faces the second threat: the public release or sale of its most confidential information. This significantly complicates the decision-making process, as the potential consequences of data exposure—including loss of competitive advantage, customer trust, and severe legal penalties—can be even more devastating than the initial operational downtime. This evolution has made ransomware attacks far more lucrative for criminals and exponentially more damaging for the manufacturing businesses they target.

Forging a Resilient Future

The escalating frequency and sophistication of these multifaceted attacks demanded an urgent and proactive response from the manufacturing sector. It became clear that a reactive stance was no longer tenable; manufacturers had to adapt by fundamentally rethinking their approach to cybersecurity. This involved bolstering cyber defenses with robust, modern security mechanisms specifically designed for integrated IT and OT environments. Maintaining constant vigilance for new vulnerabilities and prioritizing the development of a thorough, well-rehearsed incident response plan emerged as critical pillars of this new strategy. The goal was to build resilience and mitigate the potentially devastating impact of a successful attack, shifting the industry’s mindset from prevention alone to a comprehensive strategy that encompassed detection, response, and rapid recovery.