A surge in sweet–salty snacking has turned a humble coated pretzel into a savvy manufacturing play, and the latest industry blueprint details how a modern plant can convert that appetite into dependable margins while meeting rigorous standards, scaling output, and balancing channel risk across retail and e-commerce. Beyond product buzz, the appeal rests on repeatable steps, affordable inputs, and a clear path to premium price points through chocolate grades, toppings, and giftable packaging. The plan lays out a full arc: where to build, how to automate, which checks to enforce, and how to model cash flows under shifting demand and energy costs. It frames plant design as a system—integrating quality protocols, digital traceability, and energy management—so decision-makers can align throughput targets with staffing, utilities, and packing formats without sacrificing compliance or flexibility.

Scope and Audience

The report served operators who needed more than a checklist; it offered a working playbook for building and scaling a chocolate-covered pretzel line from concept to commercialization. Entrepreneurs found a roadmap for translating a flavor idea into a viable bill of materials and a repeatable process, while investors used the underlying model to test capex timing, debt coverage, and channel mix scenarios. Consultants and strategists drew on benchmarks for yields, changeover windows, and staffing norms that tie directly to line speed. The guidance connected layout choices to cost outcomes, demonstrating how zoning, conveyance, and cooling capacity affect labor efficiency, scrap, and pack variability.

Moreover, the scope acknowledged that success depends on the intersections between engineering, market access, and compliance. It mapped how product architecture—base shapes, chocolate type, toppings, and pack sizes—should align with the realities of supermarket resets, convenience store facings, online fulfillment, and corporate gifting calendars. It also showed how a plant’s automation level should match demand volatility: semi-automated cells for early-stage runs, progressing to in-line enrobing and robotics as velocity grows. Throughout, the audience was pushed to treat food safety, data capture, and sustainability as table stakes rather than optional upgrades.

Market Positioning and Growth Drivers

Chocolate-covered pretzels straddle confectionery and salty snacks, delivering a contrast of crunch, salt, and cocoa that unlocks impulse buys and gifting occasions. The category stretches well beyond holiday tins; single-serve pouches, family bags, and premium assortments broaden the addressable market, while drizzle finishes, nut inclusions, and specialty chocolates underpin segment trade-up. Retail expansion has been steady, supported by eye-catching packs and shelf-ready cases that trigger quick grabs. Online channels have accelerated discovery and seasonal drops, and corporate orders drive reliable volume spikes tied to recognition programs and festive periods.

Demand strength has also aligned with macro shifts: higher disposable incomes in key regions, rising snacking frequency, and a tolerance for indulgence when portioned smartly. A “better-for-you” thread emerged too, with interest in lighter coatings, protein-forward pretzel bases, reduced sugar, and clean-label claims. The outlook remained upbeat as brands diversified formats, added limited-time flavors, and aligned packaging with sustainability aims. The throughline was flexibility: the same core line can produce standard, premium, and gift packs by sequencing coatings and toppings and swapping packaging change parts, allowing operators to chase growth while protecting utilization.

Operations and Automation Blueprint

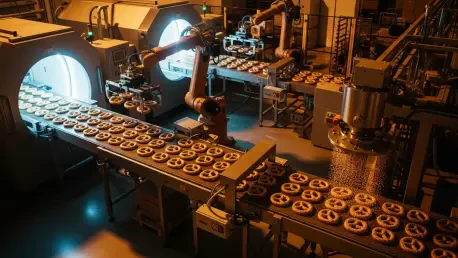

Operationally, the process followed a disciplined sequence: incoming pretzels were inspected for size and salt uniformity; chocolate was melted and tempered to meet gloss and snap targets; enrobing or dipping ensured consistent coverage; cooling tunnels set the coating; toppings were applied with controlled deposition; finished pieces passed through metal detection and vision checks before primaries and case packing. Mass balance tracking, allergen segregation, and sanitation cycles anchored the system. Compliance with HACCP and ISO 22000 created the backbone for retailer audits, while digital records supported traceability and export readiness. Yield protection hinged on temperature, viscosity, and belt speed control to reduce bloom and waste.

Automation choices were positioned as levers, not a binary. Entry lines might pair compact tempering with mid-speed enrobing and modular conveyors; higher-output plants folded in robotics for de-panning, lane balancing, and case packing, plus vision systems to monitor coverage and topping density in real time. Sensors watched tunnel temperatures, chocolate temper windows, and humidity to stabilize quality across shifts. A connected stack—SCADA for utilities, MES for work-in-process, and inline QC dashboards—tightened decision loops and trimmed rework. Over time, predictive maintenance on pumps, gearmotors, and chillers reduced downtime and flattened overtime spikes during seasonal peaks.

Plant Setup, Sustainability, and Compliance

Site selection favored proximity to distribution corridors and reliable utilities, with particular attention to power quality and HVAC capacity for chocolate handling. Layouts segmented raw, process, and finished zones; linear flow cut cross-traffic, protected allergens, and shortened travel. Dedicated storage for chocolate blocked thermal swings, while pretzel storage controlled humidity to preserve crispness. Packaging rooms were sealed to manage particulates and temperature, ensuring seal integrity. Staff plans balanced operators, QA techs, maintenance, sanitation, and shift leads, with cross-training to cover changeovers and peak windows. Safety and GMPs governed foot traffic, handwashing, and gowning, embedding audit readiness into daily routines.

Sustainability was treated as a cost and brand strategy, not only an ethical aim. Smart metering tracked electricity for tempering and cooling, water use for sanitation, and compressed air loads; the data set enabled reduction projects that paid back quickly. Lines were designed for reduced changeover waste via quick-release parts and recipe management. Packaging shifted toward recyclable films, paper-based outers, and right-sized cases, with labeling that supported stewardship claims. Alongside HACCP and ISO 22000, plants pursued country-specific food safety approvals and environmental permits, aligning with retailer supplier codes. Digital traceability linked raw lots to finished cases, shrinking recall scope and bolstering customer confidence.

Financial Feasibility and Partner Support

Profit potential was framed by three dials: throughput, mix, and waste. Simple, repeatable steps with relatively low-cost inputs gave room for margin, while premium chocolates, toppings, and gift formats unlocked price tiers that offset promotional pressure. A thoughtful pack-price ladder let brands serve entry, core, and premium consumers without cannibalization. Waste reduction mattered as much as line speed; tighter temper control and precise deposition cut giveaway and rework. Channel mix played a defensive role: supermarkets supplied velocity, convenience stores drove impulse, e-commerce yielded higher average order value, and corporate gifting delivered dependable peaks that aided capacity planning.

The financial model translated these drivers into capex, opex, and returns. Capital included land, build, utilities, machinery, and the digital stack needed for QA and energy monitoring. Operating costs accounted for raw materials, labor on automated lines, maintenance, consumables, packaging, logistics, and overhead. The P&L rolled up margin forecasts; break-even timing, NPV, taxes, and depreciation rounded out the view. Sensitivity runs tested automation levels, flavor mix, energy prices, and channel allocations to reveal risks and buffers. The approach reduced guesswork, anchored lender discussions, and set KPIs for go-live, cash conversion, and reinvestment cadence.

Partner Services and FAQs Snapshot

Support functions extended beyond market sizing to hands-on execution: market entry strategy, incorporation, licensing, and supplier vetting; line design and layout; equipment selection and procurement; and benchmarking against peer productivity. Competitive analysis guided flavor roadmaps and pricing corridors, while branding and sales strategies mapped packaging formats to channel needs. Financial modeling tied layout and automation to labor per unit and energy intensity, providing a credible bridge between engineering choices and board-level ROI expectations. The result was a cross-functional plan that integrated compliance, quality, and profitability without leaving gaps at commissioning.

Common questions were handled with practical guardrails. Essential equipment at start-up included melting and tempering, an enrober or dipping station, conveyors, a cooling tunnel, metal detection and vision, and a right-sized primary and case pack line; automation could scale with orders. Demand signals looked favorable, buoyed by the sweet–salty trend and a dependable gifting cadence. Setup costs trended lower than many confectionery lines due to streamlined processes and basic inputs, though automation choices created wide bands. Required certifications centered on HACCP and ISO 22000, plus local food safety approvals, with strict attention to allergen controls and environmental permits.

Roadmap From Validation To Scale

Launching a plant demanded concrete next steps: confirm channel targets, lock product architecture, and align equipment specs with throughput and changeover goals; then finalize layout with zoning, allergen control, and utility sizing to safeguard chocolate temper stability. Commissioning plans benefitted from training tied to SOPs, CCP monitoring, and digital QA logs. Seasonal readiness hinged on inventory buffers for chocolate and pretzels, tested maintenance windows, and packaging materials scheduled ahead of gifting spikes. With those pieces set, the model supported staged automation, funding tranches, and expansion into better-for-you variants that kept momentum without straining lines.

By the end, the path to returns had been framed in executable terms rather than abstractions. Operations translated into measurable yields and labor rates, packaging choices mapped to channel lift, and compliance embedded itself in routines instead of emergency fixes. The feasibility math captured volatility in energy and demand while spotlighting levers for waste, mix, and price. Plant teams exited with a synchronized plan for quality, safety, and capacity growth, and leadership held a defensible timeline for break-even and reinvestment. The category’s appeal remained intact, but the advantage belonged to operators who treated data, design, and discipline as the core ingredients.