In a world where manufacturing is constantly evolving, 3D printing stands out as a transformative force, breaking barriers in both scale and sustainability with remarkable advancements in large-format printing and the use of recycled materials. These cutting-edge developments in additive manufacturing (AM) are not merely technical feats; they represent a shift toward more efficient, cost-effective, and environmentally conscious production methods. Imagine a technology capable of crafting everything from towering architectural structures to intricate medical devices, all while repurposing waste into valuable resources. This dual focus on expansive capabilities and eco-friendly practices is redefining what’s possible in industries ranging from aerospace to education. The excitement around these innovations stems from their potential to solve real-world challenges, whether it’s slashing production timelines or addressing the pressing issue of global plastic waste. As companies and academic institutions push the boundaries, the impact of these technologies is becoming increasingly tangible, offering a glimpse into a future where manufacturing is both powerful and responsible. Let’s dive deeper into how large-format printing and recycled materials are shaping this dynamic landscape.

Expanding Horizons with Large-Format Printing

Revolutionizing Size and Versatility

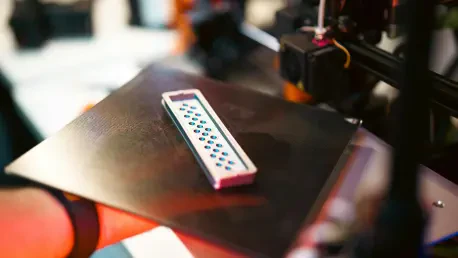

Large-format 3D printing is unlocking unprecedented opportunities by enabling the production of massive components with a level of precision that was once unimaginable for such scales. Machines like the MAMA-1700 from Modix Modular Technologies boast an impressive build volume, capable of handling projects as diverse as full-scale architectural models and components for wind turbines. This capability eliminates the need to assemble multiple smaller parts, streamlining workflows in industries such as construction and aerospace where size and structural integrity are paramount. The ability to produce oversized prototypes or end-use products in a single print run not only saves time but also reduces potential points of failure in assembly. As a result, manufacturers can take on ambitious projects that were previously out of reach, pushing the boundaries of design and functionality in ways that traditional methods could never achieve. This shift toward scalability is proving to be a game-changer for sectors demanding both innovation and efficiency.

Beyond the sheer size, the versatility of large-format printers adds another layer of transformative potential to modern manufacturing. These systems are engineered to adapt to a variety of applications, from creating detailed interior design elements to rugged industrial parts, all within the same robust framework. The flexibility to switch between different project types without requiring multiple machines or extensive retooling is a significant advantage for businesses looking to optimize resources. This adaptability is particularly evident in academic and research settings, where institutions are using such technology to explore new frontiers in prototyping and material science. For industries like automotive or marine engineering, where large, customized components are often needed, this technology offers a direct path to innovation. The seamless integration of scale and precision ensures that even the most complex designs can be brought to life with minimal compromise, setting a new standard for what additive manufacturing can accomplish in high-demand environments.

Cost Efficiency and Material Flexibility

One of the standout benefits of large-format 3D printing lies in its ability to drastically reduce production costs through the use of affordable materials like pellets, alongside traditional filament. This dual-material approach, exemplified by advanced systems such as the MAMA-1700, allows manufacturers to choose the most cost-effective option without sacrificing quality or performance. Pellets, often significantly cheaper than filament, open the door to large-scale production at a fraction of the usual expense, making it feasible for smaller businesses or research facilities to adopt this technology. This cost efficiency is particularly impactful in fields like architecture, where creating full-sized mockups or functional parts can be prohibitively expensive with conventional methods. By lowering the financial barrier, large-format printing democratizes access to advanced manufacturing, enabling a broader range of creators to experiment and innovate without the burden of exorbitant material costs.

Equally compelling is the material flexibility that large-format printers bring to the table, supporting an extensive array of polymers and composites tailored to specific project needs. From standard options like PLA and ABS to more specialized choices such as Nylon and recycled plastics, these machines cater to a wide spectrum of applications, whether it’s lightweight prototyping or heavy-duty functional parts. This adaptability ensures that industries ranging from interior design to heavy manufacturing can find suitable materials for their unique challenges, enhancing both creativity and practicality. The inclusion of sustainable options further aligns with growing environmental concerns, allowing companies to maintain eco-friendly practices while still achieving high-quality results. As material science continues to evolve alongside printing technology, the potential for custom blends and innovative compounds only expands, promising even greater versatility for future projects and solidifying large-format printing as a cornerstone of modern additive manufacturing.

Sustainability Through Recycled Materials

Turning Waste into Opportunity

At the forefront of sustainable innovation in 3D printing is the remarkable ability to transform industrial waste into valuable resources, a concept vividly demonstrated by initiatives like the “Polymer to Purpose” project from the University of Western Australia. This student-led effort focuses on repurposing high-grade recycled polymers from decommissioned subsea infrastructure into usable filament for additive manufacturing. The applications are as inspiring as they are practical, ranging from crafting affordable prosthetics to building components for tiny homes that address housing shortages. By turning discarded materials into functional products, this approach not only reduces environmental clutter but also delivers tangible social benefits, proving that technology can serve humanity in profound ways. Such projects highlight how additive manufacturing can tackle the dual challenges of waste management and accessibility, offering solutions that resonate on both local and global scales with a clear focus on real-world impact.

The momentum behind using recycled materials extends beyond isolated projects, reflecting a broader movement within the industry to prioritize sustainability without compromising on quality or innovation. By integrating waste-derived polymers into production, manufacturers can significantly cut down on the demand for virgin plastics, which often carry a heavy environmental footprint due to resource extraction and processing. This shift is particularly crucial in addressing the global plastic waste crisis, where millions of tons of discarded materials end up in landfills or oceans each year. The ability to create high-performance products from recycled sources challenges the notion that eco-friendly practices must come at the expense of functionality. Instead, it showcases how advanced filament production techniques can maintain, or even enhance, the structural integrity of printed items, paving the way for wider adoption across sectors like healthcare and construction where durability and cost are critical factors.

Aligning Innovation with Eco-Goals

The synergy between large-format 3D printing and recycled materials offers a powerful avenue for aligning technological progress with environmental stewardship, a balance that is increasingly vital in today’s manufacturing landscape. Printers capable of handling large builds, such as those developed by Modix, are being designed to work seamlessly with recycled plastics, ensuring that sustainability is embedded into even the most ambitious projects. This compatibility means that massive components, which might otherwise require vast amounts of new raw materials, can now be produced using repurposed resources, significantly reducing waste and energy consumption. Industries like architecture and infrastructure development stand to gain immensely, as they can create large-scale structures while adhering to green building standards. This integration signals a maturing of additive manufacturing, where environmental considerations are no longer an afterthought but a core component of design and production strategies.

Moreover, the push to incorporate recycled materials into 3D printing reflects a growing recognition of the industry’s role in achieving broader ecological objectives, such as reducing carbon footprints and promoting circular economies. By sourcing materials from waste streams, companies can close the loop on production cycles, ensuring that resources are reused rather than discarded after a single use. This approach not only mitigates the strain on natural resources but also fosters innovation in material processing, as engineers develop new ways to refine and enhance recycled polymers for high-performance applications. The ripple effects are felt across supply chains, encouraging suppliers and manufacturers to rethink traditional practices in favor of more sustainable alternatives. As these efforts gain traction, they set a precedent for other technologies to follow, positioning additive manufacturing as a leader in the quest for a more sustainable industrial future.

Shaping the Future Through Industry and Education

Bridging Industrial Needs and Academic Innovation

Large-format 3D printing is not confined to industrial powerhouses; it is also carving out a significant presence in academic and research environments, fostering a bridge between practical application and theoretical exploration. Institutions like Vilnius Tech in Lithuania have embraced technologies such as the MAMA-1700 to push the boundaries of manufacturing processes, using these powerful tools to test novel ideas and materials in controlled settings. This adoption allows researchers to simulate real-world industrial challenges, from prototyping large components to optimizing print parameters for efficiency, all while training the next generation of engineers and designers. The collaboration between academia and industry ensures that innovations developed in labs can be rapidly translated into commercial solutions, accelerating the pace of technological advancement. Such partnerships highlight the critical role of educational institutions in shaping the trajectory of additive manufacturing.

The academic embrace of large-format printing also serves as a catalyst for interdisciplinary learning, blending fields like engineering, material science, and design under a single innovative umbrella. Students and researchers gain hands-on experience with cutting-edge equipment, preparing them to tackle complex problems in industries ranging from aerospace to urban planning. This exposure is invaluable, as it equips emerging professionals with the skills to address both current and future manufacturing demands with creativity and technical prowess. Beyond skill-building, universities often act as testing grounds for experimental applications that might be too risky or costly for commercial entities to undertake initially. By providing a space for trial and error, academic settings contribute to refining large-format technologies, ensuring they are robust and versatile before widespread industrial adoption. This dynamic interplay between education and application is essential for sustaining long-term growth in the field.

Driving Social and Environmental Change

Projects leveraging recycled materials in 3D printing often transcend technical achievements, embedding themselves in efforts to address pressing societal needs with innovative solutions. The “Polymer to Purpose” initiative at the University of Western Australia exemplifies this, as it not only recycles industrial waste into filament but also channels these materials into creating life-changing products like prosthetics and housing solutions. Such endeavors underscore the potential of additive manufacturing to bridge gaps in access to essential goods, particularly in underserved communities where cost and availability are major barriers. By focusing on social impact, these initiatives demonstrate that technology can be a force for equity, offering affordable alternatives that improve quality of life while maintaining a commitment to environmental responsibility. This dual focus on people and planet sets a powerful example for how innovation can be harnessed for broader good.

Additionally, the emphasis on sustainability through recycled materials in educational projects inspires a cultural shift among young innovators, embedding eco-conscious values into the foundation of future technological development. Students involved in such programs gain a firsthand understanding of how waste can be reimagined as a resource, challenging conventional notions of production and consumption. This mindset is crucial for fostering a generation of professionals who prioritize green practices as a fundamental aspect of their work, rather than an optional add-on. The visibility of these projects, often recognized through national competitions and partnerships, amplifies their influence, encouraging other institutions and industries to adopt similar approaches. As more stakeholders witness the tangible benefits of combining recycled materials with advanced printing technologies, the momentum for systemic change grows, promising a future where sustainability and innovation are inextricably linked in the realm of manufacturing.

Reflecting on Transformative Steps Forward

Looking back, the strides made in large-format 3D printing and the integration of recycled materials mark a pivotal chapter in the evolution of additive manufacturing. These advancements tackle critical challenges, from enabling the creation of massive, precise components to repurposing waste into functional, high-value products. The impact is felt across industries and academic circles alike, as technologies like the MAMA-1700 redefine scalability, while initiatives such as “Polymer to Purpose” showcase the power of sustainable innovation. Moving forward, the focus should shift to scaling these solutions, ensuring that cost-effective, eco-friendly practices become the norm rather than the exception. Stakeholders must invest in further research to refine material compatibility and printer capabilities, while policymakers could incentivize adoption through grants or regulations that reward green manufacturing. Collaboration between industry leaders and educational institutions remains key to nurturing talent and ideas that will drive the next wave of breakthroughs, ensuring that additive manufacturing continues to evolve as a cornerstone of responsible, forward-thinking production.