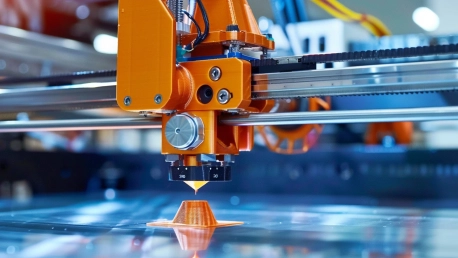

The manufacturing sector is in the midst of a transformative shift, with 3D printing technologies taking a dominant role. A 3D Printing Trend Report, drawing from a survey of over 700 engineering professionals and market data, reveals the significant growth of additive manufacturing and its implications for various industries. Now, let’s delve deeper into the expansive market growth, industry sectors, regional trends, cost savings, and the promising integration of AI that shape the future of manufacturing.

The Explosive Market Growth of 3D Printing

The Surging Market Value of Additive Manufacturing

The 3D Printing Trend Report frames an industry on the precipice of exponential growth, with projected strides to $28.1 billion by 2024 and a robust potential to nearly double to $57.1 billion by the end of 2028. These figures not only point to a notable upswing but also eclipse prior market assumptions. Indeed, the momentum at which 3D printing is expanding cannot be overstated, with an anticipated growth rate of 10.5%, showcasing the technology’s escalating endorsement and integration within production streams across the globe.

The Shift from Prototyping to Manufacturing

This leap is further illustrated by a seismic shift in industry attitudes; 70% of firms underline an uptick in 3D printed parts production this year, eclipsing the figures from the year prior. What was once the realm of prototyping has now cascaded into the domain of manufacturing at scale, signaling a revolutionary paradigm shift. The report’s findings speak volumes, flaunting the evolution of 3D printing from a niche prototype facilitator to an indispensable asset in the manufacturing toolbox.

Industry Sectors and Geographical Trends

High Potential for Transformation in Diverse Sectors

Certain sectors loom large on the transformative horizon of 3D printing. The medical field, according to the report, sits at the pinnacle, with 77% of the survey participants affirming its expansive role. Not to be sidelined, the agriculture and electronics industries are recording palpable adoption increases at 87% and 83%, respectively. Groundbreaking innovations and increased efficiency make additive manufacturing an alluring option for these industries, revolutionizing the way they approach production and design challenges.

Regional Leaders in 3D Printing Adoption

Geographically, the zeal for 3D printing is not evenly dispersed, with specific regions seizing the lead. Spain and Portugal emerge as frontrunners in Multi Jet Fusion (MJF) technology, closely followed by the technological prowess of the UK and Ireland. These distinctions highlight a diverse adoption landscape of 3D printing technologies across different regions, reflecting variegated approaches to embracing and leveraging this growing tech wave.

Cost Savings and Efficiency Gains

Reduction in Lead Times and Cost Savings

Speed and thrift—that’s the language manufacturing understands best, and it’s no different with 3D printing. Nearly half of the surveyed engineers attribute their pivot to 3D printing to its ability to slash lead times, underscoring the urgency of fast-tracked production cycles. Moreover, a resounding 82% have benefited from 3D printing’s cost-effectiveness, underscoring the potent fiscal advantages it confers on operations that embrace it.

Production-Scale Utilization of 3D Printing

What speaks to the industry even more eloquently than sentiment is revenue, and 3D printing is staking its claim there as well. Protolabs, emblematic of this growth, reportedly accrued over $84 million from its 3D printing services in 2023. The increasing instances of companies printing batches surpassing 10 units signal a robust confidence in the technology for full-scale production, aligning with broadening interest and investment in additive manufacturing capabilities.

Material Innovations and Artificial Intelligence

Advancements in Printing Materials

At the bedrock of 3D printing’s march forward are the advancements in materials, engineered explicitly for additive manufacturing techniques. With material innovations tailored to achieve high-temperature resistance or enhanced flexibility, the industry is inciting a chain reaction of creative applications that would have been inconceivable under traditional manufacturing paradigms. Each new material paves the way for ingenuity, cementing 3D printing’s standing as a harbinger of customizable and specialized outputs.

AI Integration in Additive Manufacturing

The report also shines a spotlight on the fusion of artificial intelligence with 3D printing, suggesting vast potential for process refinement and user experience enhancement. The advent of smarter printers equipped with automated tuning capabilities, coupled with advanced slicer software, postulates a near future where precision and ease-of-use are the norms. This AI infusion hints at the maturation of 3D printing into an even more intuitive and potent manufacturing force.

The Maturing Industry of 3D Printing

The Rise of Strategic Investments and Commitment to Innovation

As the industry burgeons, so does the strategic focus on innovation and the accrual of investments. Companies are increasingly recognizing that integrating 3D printing into their production arsenal is not just shrewd but necessary. This yearning for innovation is propelling the technology forward, marking it as an essential, rather than optional, factory fixture.

The Increased Adoption Across Various Sectors

The industrial landscape is being radically altered by the emergent dominance of 3D printing tech. Highlighted by a substantial 3D Printing Trend Report, a comprehensive perspective is formed through insights from over 700 engineers and robust market statistics. This report underscores the rapid expansion of additive manufacturing and delineates its vast potential across diverse sectors. We’re now poised to explore this significant market evolution, pinpoint the industrial areas most affected, recognize regional shifts, acknowledge cost-efficiency gains, and anticipate the impactful synergy of AI with upcoming manufacturing paradigms. This pivotal juncture in manufacturing presages not just a change in production techniques, but a revolution in how industries will conceive and execute the fabrication of products. Looking forward, this integration of cutting-edge technologies stands as a testament to a future rich with innovation and efficiency.