Manufacturing is undergoing a significant transformation, driven primarily by the integration of advanced robotics and artificial intelligence (AI). These groundbreaking technologies are not only enhancing efficiency, precision, and productivity but are also fostering innovation across various sectors, making the manufacturing landscape more dynamic and competitive. This article delves into the myriad facets of this transformation, emphasizing how robotics and AI are radically reshaping modern manufacturing and setting new benchmarks for what the industry can achieve.

The Rise of Advanced Robotics in Manufacturing

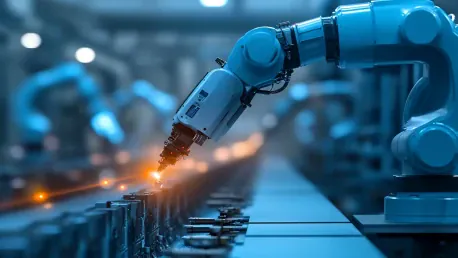

The adoption of advanced robotics in manufacturing is accelerating at an unprecedented rate, particularly in industries like automotive production. In the United Kingdom, the automotive industry is spearheading this revolution, commonly referred to as the Fifth Industrial Revolution (5IR). Companies are rapidly integrating next-generation robotics to automate processes that were once labor-intensive and prone to human error. These robots can perform complex tasks with exceptional precision, thereby significantly reducing the need for human intervention and minimizing the margin for error.

The benefits of advanced robotics extend beyond mere efficiency gains. These robotic systems also contribute to safer working environments by taking over tasks that would otherwise pose significant risks to human workers. This shift toward automating hazardous operations not only enhances overall operational safety but also allows human workers to concentrate on more strategic and creative aspects of manufacturing. This reallocation of human resources enables companies to innovate and develop new products and processes, further propelling the industry forward.

In addition to operational safety and efficiency, advanced robotics bring substantial economic benefits. The increased automation results in higher production rates and lower operational costs, improving the bottom line for manufacturers. The ability to scale production quickly and efficiently in response to market demands also provides a competitive edge. As the technology behind these robots continues to evolve, we can expect even greater advancements in the capabilities and applications of robotic systems in manufacturing.

Strengthening Supply Chains with AI

A robust and agile supply chain is indispensable for the success of any manufacturing operation, and AI is playing a pivotal role in strengthening supply chains by improving demand forecasting and inventory management. Accurate demand forecasting is essential for avoiding the financial pitfalls associated with either stock shortages or excess inventory. Advanced AI algorithms have the capability to analyze vast amounts of data, identifying patterns and predicting demand with a high degree of accuracy. This enables manufacturers to optimize their inventory levels, reduce waste, and ensure that they can meet customer demands promptly.

However, AI’s impact on supply chains goes beyond demand forecasting. AI enhances supply chain agility by providing real-time insights into every aspect of supply chain operations. These insights enable manufacturers to respond swiftly to disruptions and changes in market conditions, ensuring that they can maintain operational continuity even in the face of unexpected challenges. This agility is particularly crucial in today’s dynamic economic landscape, where supply chain resilience can significantly influence a company’s success or failure.

Moreover, AI-powered supply chain management systems can identify inefficiencies and bottlenecks in the production and distribution processes. By addressing these issues proactively, manufacturers can enhance their overall operational efficiency and reduce costs. The integration of AI into supply chain management is not just a trend but a necessity for companies looking to stay competitive in an increasingly technology-driven market.

Enhancing Security with Zero Trust Network Access (ZTNA)

In the realm of IT and security, manufacturing companies face the critical decision of choosing between Zero Trust Network Access (ZTNA) and traditional Virtual Private Networks (VPNs). While VPNs have long been the go-to solution for securing remote access to corporate networks, ZTNA offers a more secure and dynamic alternative. Unlike VPNs, which grant broad access to the network, ZTNA operates on the principle of least privilege, ensuring that users can only access the resources they need for their specific tasks.

The adoption of ZTNA is driven by the increasing recognition of cybersecurity as a strategic priority for manufacturers. With the frequency and sophistication of cyber threats continually evolving, relying on outdated security solutions can leave companies vulnerable to attacks. Implementing ZTNA provides robust defense against these evolving threats, safeguarding sensitive data and intellectual property. This shift toward more advanced security solutions is essential for building trust with customers and partners, who increasingly expect companies to prioritize data protection.

Furthermore, the adoption of ZTNA aligns with broader digital transformation initiatives within the manufacturing sector. As manufacturers adopt more connected and automated systems, the need for secure and flexible network access becomes even more critical. ZTNA provides the scalability and adaptability required to support these advanced systems, ensuring that security measures keep pace with technological advancements.

Addressing Talent Shortages in Manufacturing

One of the most pressing challenges facing the modern manufacturing sector is the acute shortage of skilled talent. This issue is exacerbated by reshoring initiatives, a surge in retirements, and the rapidly evolving skill sets required for advanced manufacturing processes. Approximately 65% of manufacturers now cite attracting and retaining talent as their primary business challenge. To address this issue, companies are implementing comprehensive recruitment and training programs aimed at developing a skilled workforce capable of meeting the demands of modern manufacturing.

Developing and retaining talent requires a multifaceted approach. Manufacturers are investing in upskilling and reskilling programs to equip their current workforce with the necessary skills for operating advanced manufacturing technologies. These programs focus on teaching workers how to use and maintain new technologies, ensuring that they can contribute effectively to the company’s success. Additionally, companies are reimagining labor resource management to create more attractive and rewarding job opportunities, which can help attract new talent to the industry.

Creating a culture of continuous learning and development is also crucial for retaining talent. By fostering an environment where employees are encouraged to continually enhance their skills and knowledge, manufacturers can build a more resilient and adaptable workforce. This approach not only helps address the current talent shortage but also prepares companies for future challenges by ensuring they have a workforce capable of adapting to new technologies and processes.

The Impact of Political Changes on Global Trade

Political changes, especially those stemming from US elections, have a far-reaching impact on global trade and manufacturing strategies. Different administrations can either encourage protectionist measures or promote international partnerships, significantly reshaping global supply chain dynamics. For manufacturers, this means continuously adapting their strategies to align with the prevailing political climate to mitigate risks and capitalize on opportunities arising from political developments.

The uncertainty surrounding political changes necessitates a proactive approach to strategic planning. Manufacturers must build resilience and agility into their operations to navigate potential shifts in trade policies, taxes, and regulations. This involves closely monitoring political developments, assessing their potential impact on the business, and developing contingency plans to address various scenarios. By staying informed and prepared, companies can mitigate risks associated with political instability and ensure that their operations remain viable.

Moreover, political changes can also influence market access and competitiveness. For example, an administration that promotes protectionist measures may impose tariffs or trade barriers that affect the cost and availability of imported goods. Conversely, policies that encourage international partnerships can open new markets and create opportunities for growth. Manufacturers need to be agile in their strategic planning to quickly adapt to these changes and maintain their competitive edge in the global market.

Leveraging Large Format Additive Manufacturing (LFAM)

Large Format Additive Manufacturing (LFAM) is gaining traction as a viable technology for producing specific parts and components. LFAM offers optimization opportunities that traditional manufacturing methods cannot achieve, making it an attractive option for industries that require high precision and customization. Manufacturers are increasingly assessing the viability of LFAM based on its ability to meet specific requirements cost-effectively and efficiently.

The adoption of LFAM is driven by its potential to revolutionize manufacturing processes. By enabling the production of large and complex parts with high precision, LFAM reduces material waste and shortens production cycles. This technology is particularly valuable in industries such as aerospace and automotive, where precision and efficiency are paramount. Additionally, LFAM allows for greater design flexibility, enabling manufacturers to create innovative products that were previously not possible with traditional methods.

LFAM also has the potential to significantly impact supply chain dynamics. By producing parts on-demand and closer to the point of use, LFAM can reduce the need for extensive inventory and lower transportation costs. This localized production can lead to more efficient supply chains and quicker response times to market demands. As the technology behind LFAM continues to advance, we can expect its adoption to increase, further transforming manufacturing processes and supply chain strategies.

Future-Proofing Warehouses with Advanced Network Infrastructures

The manufacturing industry is experiencing a profound transformation due to the integration of advanced robotics and artificial intelligence (AI). These innovative technologies are revolutionizing the way manufacturing operates, significantly enhancing efficiency, precision, and productivity. By incorporating robotics and AI, manufacturers can streamline processes, reduce errors, and boost output, making operations more effective and reliable.

But the impact of robotics and AI extends beyond just improving existing processes. These technologies are also driving innovation within the industry, leading to the development of new methods and products. This ongoing innovation is making the manufacturing sector more dynamic and competitive, allowing companies to set new benchmarks for performance and capabilities.

The embrace of robotics and AI in manufacturing is fostering a more adaptable and responsive industry. As these technologies continue to evolve, they offer unprecedented opportunities for manufacturers to adapt to changing market demands quickly and efficiently. This article explores the various aspects of this transformation, highlighting the significant role these technologies play in reshaping modern manufacturing and pushing the industry to achieve previously unimaginable feats. By integrating robotics and AI, the manufacturing landscape is not only becoming more advanced but also setting new standards for what can be accomplished in the modern era.