The global manufacturing sector is undergoing a profound transformation, moving beyond a phase of economic contraction and tentative AI experiments toward the widespread, at-scale implementation of truly intelligent systems. This pivotal year is defined not merely by the technology itself, but by the critical challenge of creating a symbiotic relationship between aggressive, forward-looking investments and a highly adaptive, strategic approach to workforce development. The central thesis for success hinges on a manufacturer’s ability to harmonize the rise of autonomous digital agents with the cultivation of human talent. This is no longer a conversation about replacing workers with machines, but about augmenting human capability to achieve unprecedented levels of efficiency, resilience, and innovation. The companies that master this delicate balance, treating technology adoption and human capital as two halves of a single, unified strategy, will be the ones that define the next era of industrial leadership and secure a decisive competitive advantage in a rapidly evolving global market.

The Human Imperative in Smart Manufacturing

The most significant barrier to realizing the full potential of smart manufacturing is proving to be human, not technological, as a consensus viewpoint emerges across the industry. As companies pour vast capital into digital tools, automation, and intelligent factory infrastructure, the competition for skilled labor has become exceptionally intense. A recent survey underscored this anxiety, revealing that for over a third of manufacturing executives, the primary concern is equipping their workforce with the necessary skills and knowledge to effectively leverage these advanced systems. This talent strain is further exacerbated by the accelerating trend of reshoring, which, while beneficial for strengthening domestic production, places additional and significant pressure on an already limited pool of qualified workers. This creates a challenging paradox where the very investments designed to boost productivity are being constrained by the availability of people who can design, implement, and manage them effectively.

To navigate this complex and demanding talent landscape, leading organizations are adopting a flexible and multifaceted “build, buy, or borrow” framework for strategic workforce planning. This agile model encourages manufacturers to become more dynamic in how they acquire and develop critical skills. The “build” component involves making strategic, long-term investments in upskilling and reskilling the existing workforce, focusing on nurturing talent that is core to the company’s unique value proposition and future vision. In contrast, the “buy” strategy centers on actively recruiting external personnel who already possess specialized expertise, a crucial tactic for roles where the required skills would take too long to cultivate internally. Finally, to manage fluctuating demand and project-specific needs, the “borrow” approach involves engaging temporary workers, contractors, or specialized third-party firms, providing immediate access to skills without the long-term commitment of a full-time hire, ensuring operational continuity.

Agentic AI as the New Operational Engine

A deep-seated commitment to technological advancement underpins this industrial evolution, with a recent executive survey showing that a significant majority plan to allocate 20% or more of their improvement budgets to smart manufacturing initiatives. Initial investments have concentrated on foundational technologies like automation hardware, advanced data analytics, ubiquitous sensors, and robust cloud computing infrastructures. However, at the forefront of the next wave of innovation is agentic AI, a technology poised to elevate smart manufacturing and operations to an entirely new level. Unlike traditional AI, which primarily analyzes data and provides insights for human decision-makers, agentic systems can take autonomous action based on that analysis. This capability enables a far more proactive and intelligent operational environment, with applications ranging from capturing the institutional knowledge of retiring employees to autonomously engaging alternative suppliers in real-time in response to supply chain disruptions.

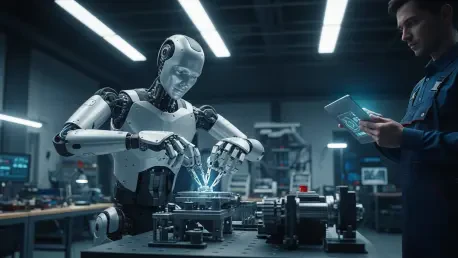

Crucially, agentic AI is positioned as the essential foundation for the deployment of sophisticated physical AI, paving the way for the next generation of advanced robotics on the factory floor. This emerging trend is rapidly gaining traction, with a recent industry survey indicating that nearly a quarter of manufacturers intend to deploy such physical AI systems within the next two years. These systems include innovations like humanoid robots capable of navigating unstructured factory environments and performing complex, non-repetitive tasks, such as installing specific components in a dynamic assembly process. By integrating agentic AI as the cognitive “brain,” these robots can operate with greater autonomy and adaptability than their predecessors. This convergence of intelligent software and capable hardware promises to not only enhance productivity but also make manufacturing jobs more appealing to younger generations by automating mundane tasks and creating new roles focused on higher-level problem-solving and system oversight.

Navigating Market Forces and a New Revenue Frontier

The trajectory of the manufacturing sector is also being heavily influenced by a confluence of powerful external economic and geopolitical factors. A massive surge in demand for AI and data center infrastructure is creating a significant downstream growth opportunity for industrial equipment manufacturers. This boom is evidenced by massive investment in related sectors and government initiatives designed to bolster domestic semiconductor production. This has led to a situation where large OEMs are reporting multi-year backlogs for essential components like transformers, switchgear, and power management equipment. Simultaneously, however, trade uncertainty remains a dominant concern for the majority of industry members, suggesting that sourcing challenges and trade volatility are likely to persist. In this complex environment, agentic AI offers a powerful solution by enhancing supply chain visibility and agility, autonomously monitoring global trade routes to detect potential risks and initiate mitigation strategies.

Amid these external pressures, the strategic importance of aftermarket services as a key driver of profitability and stability was illuminated. These services—encompassing maintenance, repairs, and spare parts—delivered profit margins that more than doubled those of original equipment sales while creating predictable, less cyclical revenue streams for manufacturers. Agentic AI was set to revolutionize this segment by enabling proactive and autonomous service delivery. By processing vast amounts of data across multiple internal and external systems, an agentic AI system could, for instance, detect component wear based on real-time usage patterns. It then autonomously triggered a cascade of actions: it ordered the necessary replacement parts, reallocated inventory to ensure availability, scheduled a service appointment with the customer, managed the part’s delivery logistics, and even optimized future manufacturing quantities for that specific component—all with minimal human intervention, which dramatically reduced response times and minimized customer downtime.