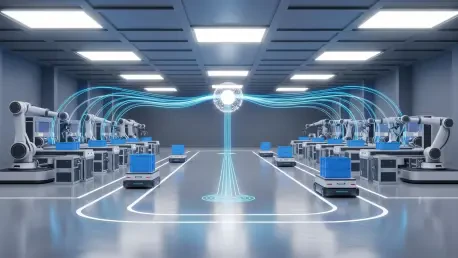

The once-predictable rhythm of the factory floor is now being orchestrated by intelligent systems that think, learn, and adapt in real time, fundamentally redefining what it means to manufacture goods at scale. Agentic AI represents a significant advancement in the manufacturing sector, paving the way for a new generation of smart, autonomous factories. This review will explore the evolution of this technology, its key features, performance metrics, and the impact it has had on various industrial applications. The purpose of this review is to provide a thorough understanding of agentic AI, its current capabilities, and its potential for future development.

The Shift from Automation to Autonomy

The core distinction of agentic AI lies in its departure from traditional, rule-based automation. While conventional systems excel at executing predefined, repetitive tasks, agentic AI introduces a layer of cognitive ability. These systems are designed to perceive their environment, reason through complex scenarios, and act autonomously to achieve specific goals, making them inherently flexible and responsive to dynamic conditions on the factory floor.

This transition from rigid automation to intelligent autonomy is the foundational principle of the modern “smart factory.” Agentic AI enables the creation of adaptive manufacturing ecosystems capable of real-time learning and self-adjustment. Instead of relying on human operators to intervene when disruptions occur, these systems can independently recalibrate processes, optimize workflows, and maintain operational continuity, driving a new standard of efficiency and resilience.

Core Capabilities of Agentic AI Systems

Adaptive Scheduling and Process Optimization

Agentic systems leverage a constant stream of real-time data from IoT sensors and edge devices to dynamically adjust production schedules and operational processes. By monitoring variables like machine availability, material supply, and order priority, these AI agents can make intelligent decisions on the fly. This capability allows them to reroute tasks to avoid bottlenecks, reallocate resources to meet urgent demands, and optimize the overall production flow without manual intervention.

The practical impact of this adaptability is profound. Manufacturers can manage the inherent complexities of material flow, machine performance, and fluctuating market demand with greater precision. This proactive approach minimizes delays, reduces idle time, and ensures that the factory operates at peak efficiency, transforming production planning from a static, periodic activity into a continuous, self-correcting process.

Intelligent Quality Control

In the domain of quality assurance, AI-powered vision systems and advanced analytics are far surpassing the speed and accuracy of manual inspection. These agentic systems can identify microscopic defects, subtle material flaws, and assembly errors that are often invisible to the human eye. Operating continuously and in real time, they ensure that every product meets exacting standards before it moves to the next stage of production.

This shift toward automated quality control significantly reduces rework costs and material waste. By catching errors at their source, manufacturers prevent flawed components from progressing through the assembly line, which improves final product quality and enhances customer satisfaction. The result is a more reliable and cost-effective production cycle.

Predictive and Prescriptive Maintenance

Agentic AI is revolutionizing equipment maintenance by shifting the paradigm from reactive to proactive. By continuously analyzing operational data such as vibration, temperature, and torque, these systems can accurately predict potential machine failures before they occur. This predictive capability allows maintenance teams to schedule repairs at convenient times, avoiding catastrophic breakdowns during critical production runs.

This approach has been shown to reduce unplanned downtime by up to 30%, a significant improvement that directly impacts productivity and profitability. Furthermore, some systems offer prescriptive guidance, not only flagging an impending failure but also recommending the specific actions needed to resolve the issue. This transforms maintenance into a data-driven, strategic function that extends asset life and optimizes operational uptime.

Driving Forces Behind Adoption

Economic and Operational Imperatives

A confluence of market pressures is accelerating the push toward agentic AI. Persistent labor shortages in the manufacturing sector, coupled with rising operational costs associated with downtime and rework, have created a clear business case for intelligent automation. Companies are increasingly seeking solutions that can enhance productivity and reduce their reliance on manual processes.

Moreover, the modern global market demands a level of agility and resilience that traditional manufacturing struggles to provide. Agentic AI enables companies to build more flexible operations that can quickly adapt to supply chain disruptions, shifts in consumer demand, and other external pressures. This ability to pivot rapidly is becoming a critical competitive advantage.

Advancements in Enabling Technologies

The rapid growth of agentic AI is fueled by a convergence of powerful enabling technologies. The proliferation of low-cost IoT sensors has made it economically feasible to collect high-frequency data from virtually every asset on the factory floor. This constant flow of information provides the rich dataset that AI models need to learn, adapt, and make informed decisions.

Simultaneously, the rise of edge computing has been essential for translating this data into action. By processing information locally, close to the source, edge devices eliminate the latency associated with cloud-based analysis. This capability is critical for applications that require split-second decisions, such as real-time quality control or collision avoidance for autonomous mobile robots.

Impactful Implementations Across Industries

Automotive and Assembly Lines

In the automotive industry, agentic AI is already delivering substantial improvements in precision and efficiency. Industry leader BMW, for example, employs AI vision systems to detect microscopic cracks in components and to guide workers during complex assembly tasks, resulting in significant annual savings.

Similarly, Tesla has integrated AI to accelerate its quality control inspections, with automated systems now identifying weld and paint flaws 50% faster than human inspectors. These use cases demonstrate how agentic AI is being deployed to master the intricate demands of modern vehicle assembly, from enhancing component integrity to ensuring flawless final finishes.

Electronics and High Volume Production

The electronics sector, characterized by high-volume and high-precision production, is another fertile ground for agentic systems. Foxconn has notably deployed humanoid robots to perform delicate server assembly tasks, signaling a broader industry trend toward creating fully automated production lines. These systems are not only faster but also more consistent than human workers, which is critical for maintaining quality at scale.

This move toward hyper-automation allows electronics manufacturers to meet intense global demand while controlling costs. By entrusting repetitive and intricate tasks to intelligent agents, companies can achieve new levels of efficiency and throughput, solidifying their competitive position in a fast-paced market.

Logistics and Warehouse Management

The impact of agentic AI extends beyond the production line into internal logistics and material flow. Amazon’s deployment of over 1.5 million robots in its fulfillment centers serves as a prime example of this trend. These autonomous agents navigate vast warehouse floors to retrieve and transport goods, optimizing storage and accelerating order processing.

The implementation of these robotic systems has resulted in a documented 20% increase in productivity and has fundamentally streamlined warehouse operations. This showcases how agentic AI can orchestrate complex logistical tasks at a scale and speed that would be impossible to achieve with a purely human workforce.

Current Challenges and Technical Hurdles

Integration with Legacy Infrastructure

One of the most significant barriers to widespread adoption is the challenge of integrating advanced AI systems with existing, and often outdated, factory infrastructure. Many manufacturers have substantial investments in legacy equipment and IT systems that were not designed to interface with modern, data-driven technologies. Bridging this gap can be a complex and costly undertaking.

This integration hurdle often requires extensive custom development or the purchase of expensive middleware solutions, which can make implementation prohibitive for small and medium-sized enterprises. Without seamless data flow between old and new systems, the full potential of agentic AI cannot be realized, slowing its deployment across the broader industry.

Data Security and Model Reliability

The reliance of agentic AI on vast amounts of production data introduces significant security risks. This sensitive information, if compromised, could expose trade secrets or be manipulated to disrupt operations. Consequently, ensuring robust cybersecurity measures are in place to protect data both in transit and at rest is a critical prerequisite for implementation.

Beyond security, the reliability and transparency of the AI models themselves are paramount. Manufacturers must have confidence that these systems will perform predictably and safely under all conditions. The “black box” nature of some advanced AI models can be a concern, driving a need for greater model explainability and rigorous testing to prevent unexpected failures on the factory floor.

High Initial Investment and Workforce Skills Gap

Deploying agentic AI systems requires a substantial upfront capital investment in hardware, software, and integration services. This high initial cost can be a major deterrent for many companies, particularly those operating on thin margins. Calculating a clear and timely return on investment is crucial for securing the necessary funding for such transformative projects.

In addition, a significant workforce skills gap presents a concurrent challenge. The effective management, maintenance, and optimization of these advanced systems require expertise in data science, robotics, and AI. There is a pressing need for manufacturers to invest in training and upskilling their existing employees or to compete for a limited pool of qualified talent.

The Future of Autonomous Manufacturing

The Evolution Toward Lights Out Factories

The long-term vision for agentic AI in manufacturing is the realization of the “lights-out” factory—a fully autonomous production facility that can operate around the clock with minimal to no human oversight. In such an environment, intelligent agents would manage everything from raw material intake to final product shipment, achieving unprecedented levels of efficiency and productivity.

While this concept may still be on the horizon for most, the foundational technologies are already being put into place. As AI models become more sophisticated and robotics more capable, the gradual evolution toward full autonomy will continue, with certain highly standardized production processes likely to achieve this status first.

Enhancing Human Robot Collaboration

Contrary to fears of mass job displacement, the more immediate future of agentic AI is likely to be centered on enhancing human-robot collaboration. In this model, intelligent systems augment human capabilities rather than simply replacing them. AI will be tasked with handling dangerous, repetitive, or ergonomically challenging tasks, freeing human workers to focus on more creative and strategic roles.

This collaborative environment, often referred to as “cobotics,” creates a symbiotic relationship where the strengths of both humans and machines are maximized. People can contribute their problem-solving skills, creativity, and critical thinking, while AI agents provide the speed, precision, and endurance needed for modern production, leading to a safer and more fulfilling work environment.

A New Era of Intelligent Production

This review established that agentic AI has successfully transitioned from a futuristic concept to a practical solution delivering tangible benefits on the factory floor. The analysis showed how its core capabilities in adaptive scheduling, intelligent quality control, and predictive maintenance have directly addressed long-standing operational challenges. Through impactful implementations across the automotive, electronics, and logistics sectors, the technology proved its ability to drive significant improvements in efficiency and resilience. Although challenges related to integration, security, and investment remained, the economic and technological forces driving adoption have created undeniable momentum. The evidence presented confirmed that agentic AI has already begun to reshape the landscape of modern production, marking the definitive arrival of a new, intelligent manufacturing era.