The long-predicted sentient factory is no longer a futuristic concept confined to science fiction but an emerging reality, powered by intelligent agents capable of managing production with an unprecedented level of autonomy. Across the industrial landscape, a consensus is building that this shift marks the most significant manufacturing evolution since the dawn of robotics. This analysis gathers insights from industry reports, market projections, and pioneering case studies to create a comprehensive overview of how agentic artificial intelligence is not just improving but fundamentally redefining the factory floor. The purpose is to distill the core technological advancements, quantifiable benefits, and strategic imperatives driving this transformation.

Beyond the Assembly Line: The Dawn of the Sentient Factory

Manufacturing has embarked on a remarkable journey, moving from the predictable, repetitive motions of pre-programmed robotics toward intelligent systems that are both adaptive and resilient. Industry experts consistently chart this progression as a necessary response to an increasingly volatile global market, where supply chain fragility and fluctuating consumer demand have exposed the limitations of rigid production models. The critical need for operational agility has become the primary catalyst for innovation, pushing businesses to seek solutions that can withstand and even thrive amid uncertainty.

This push has given rise to a new paradigm: the self-managing production environment. Technology leaders describe these systems as ecosystems where AI agents act as digital foremen, overseeing operations with a level of insight and speed that surpasses human capabilities. These agents learn from a constant stream of data, make predictive adjustments to workflows, and execute complex tasks with minimal oversight. In essence, the vision of the sentient factory is one where the production line itself becomes an intelligent, self-optimizing entity.

The New Industrial Intelligence: How Agentic AI Is Rewiring Production

The Defining Leap from Automation to Autonomy

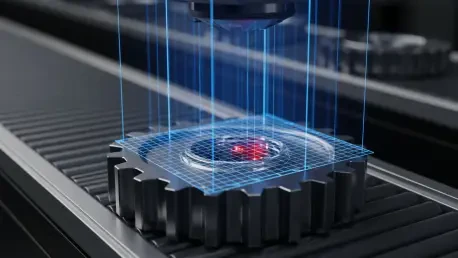

A crucial distinction made by analysts is the one between traditional automation and true autonomy. Automation follows a strict set of pre-programmed rules, executing tasks efficiently but without the ability to reason or adapt to unforeseen circumstances. Agentic AI, in contrast, represents a defining leap forward. It operates on a cycle of perceiving its environment through data, reasoning about the best course of action, and acting decisively. This ability to process real-time information and make independent decisions is what separates it from its predecessors.

The technological backbone enabling this autonomy is a powerful synergy of interconnected systems. Reports from the field highlight the critical role of Internet of Things (IoT) sensors, which are now pervasively embedded in machinery to track vital signs like vibration, temperature, and torque. This raw data is processed instantaneously by edge computing devices located directly on the factory floor, eliminating the latency of cloud-based analysis. However, a recurring challenge emphasized by integration specialists is the difficulty of merging these advanced AI systems with legacy factory infrastructure, a hurdle that requires significant strategic planning and investment.

Forging Unprecedented Agility on the Factory Floor

The most celebrated impact of agentic AI, according to operational managers, is its ability to create unprecedented agility. Real-world applications consistently demonstrate how AI-driven scheduling and intelligent routing can anticipate and resolve production bottlenecks before they disrupt the workflow. For instance, if one machine shows signs of slowing down, an AI agent can instantly reroute materials to an alternative station, ensuring that production targets are met without interruption.

This proactive capability extends powerfully to equipment maintenance. Predictive maintenance algorithms, fueled by continuous machine health data, can preempt equipment failure with remarkable accuracy. Industry-wide studies quantify the gains, with many firms reporting a reduction in operational downtime by up to 30%. The cumulative effect, as strategic analysts point out, is a hyper-flexible plant. Such facilities are far better equipped to navigate sudden supply chain disruptions or pivot production to meet unexpected shifts in market demand, creating a significant competitive advantage.

Achieving Machine-Speed Perfection in Quality Control

In the realm of quality control, expert consensus suggests that agentic AI is setting a new standard for perfection. AI-powered vision systems, capable of inspecting thousands of parts per minute, consistently achieve over 99% accuracy in defect detection. These systems can identify microscopic flaws, subtle color deviations, and hairline cracks that are often invisible to the human eye, thereby eliminating a major source of production waste and customer complaints.

Prominent benchmarks from the automotive sector offer compelling proof. BMW, for example, reported saving over $1 million annually by implementing AI for parts inspection, while Tesla has leveraged similar technology to identify weld flaws 50% faster than traditional methods. These results directly contradict the long-held assumption that experienced human oversight remains the gold standard for quality assurance. The evidence indicates that for tasks requiring tireless precision and microscopic attention to detail, machines have not only caught up but have now surpassed human performance.

The Economic Engine Driving the AI Transformation

The financial momentum behind this shift is undeniable. Market forecasts project that investment in manufacturing AI will surge from $8.57 billion in 2025 to an astounding $230.95 billion by 2034. Economic analysts attribute this explosive growth to a confluence of pressing business challenges. Persistent labor shortages in skilled manufacturing roles, the high cost of rework associated with quality escapes, and the enterprise-wide imperative for more stable and predictable throughput are all converging to make AI a strategic necessity rather than a luxury.

The value proposition of autonomy, as many observers note, extends well beyond the assembly line and into the broader supply chain. Amazon’s logistics network provides a powerful case study, where the deployment of over 1.5 million autonomous robots has boosted overall productivity by 20%. This success proves that the principles of agentic AI—perception, reason, and action—are universally applicable to complex operational environments, reinforcing the technology’s transformative potential across all facets of industrial production.

Blueprint for the Smart Factory: A Practical Integration Guide

A synthesis of expert opinions reveals that the core advantages of agentic AI form the three pillars of the modern smart factory: enhanced operational agility, superior quality assurance, and proactive predictive maintenance. These benefits are not isolated improvements but are deeply interconnected, creating a virtuous cycle where higher quality reduces rework, predictive maintenance increases uptime, and greater agility allows the entire system to respond to market needs more effectively.

For organizations looking to embark on this journey, leading practitioners recommend a strategic and phased adoption roadmap. The most successful implementations often begin with pilot projects in high-impact areas, such as a critical quality control checkpoint or a notoriously unreliable piece of machinery. These initial wins help build organizational buy-in and provide valuable lessons that can be applied to a full-scale operational overhaul. Furthermore, a foundational agreement exists among tech leaders that success is impossible without first building a robust data infrastructure and cultivating a culture where data-driven decision-making is the norm.

The Inevitable Future: Navigating the New Manufacturing Paradigm

This roundup of industry insights reinforced the central conclusion that agentic AI was not an incremental improvement but a fundamental redefinition of industrial production. The evidence gathered from market data, technological analyses, and real-world case studies painted a clear picture of a sector in the midst of a profound transformation, moving away from static processes and toward dynamic, self-governing systems.

The long-term implications discussed by strategists were far-reaching, touching on the future of global supply chains, workforce dynamics, and national economic competitiveness. The final, overarching insight was that the adoption of this technology had moved beyond a point of debate and become an essential strategy. The leaders who embraced this technological shift were not just optimizing their factories; they were positioning their entire enterprises for survival and sustained growth in an increasingly autonomous world.