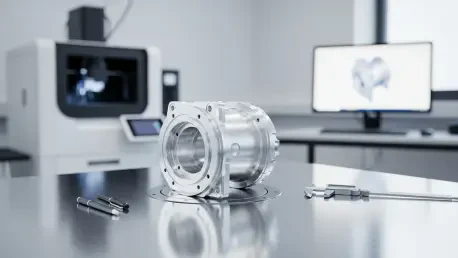

In a move designed to address critical vulnerabilities in the nation’s supply chain, Indiana-based Precision Additive has officially launched the PA-300, a revolutionary metal 3D printer that promises to redefine the landscape of domestic production. This system is not merely an incremental improvement; it is billed as the world’s fastest Laser Powder Bed Fusion (LPBF) machine and the first to be constructed with an integrated artificial intelligence architecture from its inception. The PA-300 is meticulously engineered to manufacture high-quality, qualification-ready components for America’s most demanding sectors, including defense, aerospace, energy, and medical. In these industries, where component failure can have catastrophic consequences, the printer is presented as a reliable, U.S.-based manufacturing solution engineered to meet the most stringent performance and safety requirements, heralding a new chapter for secure and intelligent industrial capabilities.

A New Era of Intelligent and Rapid Production

The PA-300’s remarkable performance stems from a powerful synergy of three core technological pillars: proprietary laser technology, embedded artificial intelligence, and a comprehensive qualification framework. At the heart of the system is its advanced SSLM™ laser technology, an innovation that enables build speeds up to ten times faster than those of conventional LPBF systems. This dramatic increase in velocity fundamentally alters the economic and logistical feasibility of additive manufacturing, transitioning it from a tool primarily used for one-off prototypes to a viable method for serial production. This speed is complemented by the Precision Additive Qualification (PAQ) framework, a data-driven system designed to ensure consistent and repeatable results from every print run. This tightly controlled process is essential for industries where parts must be certified and qualified, as it guarantees that a component produced today will be identical in every critical aspect to one produced months later, ensuring unwavering dependability.

The system’s most transformative feature is its embedded AI architecture, developed in a deep collaboration with NVIDIA to advance physics-based, AI-driven manufacturing. This intelligent system functions as a vigilant overseer, continuously monitoring the entire printing process in real time. It is designed to detect any deviations or anomalies from the design specifications as they occur. Crucially, upon identifying an issue, the AI is engineered to automatically make on-the-fly corrections. Precision Additive describes this unique capability as a “self-healing” process, which actively protects the integrity of the component being printed. This real-time monitoring and correction protocol is designed to minimize build failures, significantly improve final part quality, and ensure that every product meets exact specifications. This AI framework not only supports process optimization but also enables predictive quality assurance and provides the robust data needed for scalable qualification workflows, making the technology exceptionally reliable for mission-critical applications.

Redefining Material Capabilities and Production Economics

A key market differentiator for the PA series of machines is its exceptional ability to process a wide range of metal alloys, including materials that are notoriously difficult to work with, such as tungsten and copper. The company specifically highlights its groundbreaking capability in processing magnesium as a major breakthrough. Magnesium is a highly desirable material, particularly in aerospace, defense, and space exploration, due to its exceptionally lightweight properties. However, its highly reactive nature has historically made it extremely challenging to manufacture safely and reliably using additive technologies. The tightly controlled, AI-monitored process environment of the PA-300 effectively overcomes these long-standing obstacles. This advancement makes it possible to reliably print complex magnesium alloy components, opening new design possibilities for creating next-generation lightweight structures that were previously unattainable, thereby pushing the boundaries of performance in critical industries.

This technological leap signals a fundamental shift in the additive manufacturing landscape by directly addressing the economic barriers that have limited its widespread adoption for mass production. By dramatically increasing speed with its proprietary laser and ensuring unparalleled part quality through its integrated AI, the PA-300 fundamentally alters the cost-benefit analysis of 3D printing for large-scale manufacturing. The system is designed to empower manufacturers to move beyond the traditional use of additive technology for producing one-off prototypes. Instead, it provides a dependable and efficient platform for producing complex, high-volume parts. This shift allows for the creation of more intricate geometries, the consolidation of multi-part assemblies into single components, and the on-demand production of critical spare parts, thereby enhancing supply chain resilience and reducing reliance on traditional manufacturing methods with long lead times.

Strengthening Americas Industrial Base

According to Jon Haase, the company’s Chief Strategy Officer and President of Government Business, the development of the PA-300 was driven by a pressing strategic imperative. Haase noted that U.S. defense programs are increasingly vulnerable due to fragile global supply chains and a growing reliance on foreign sources for high-complexity parts. This dependency poses a significant risk to national readiness and security, a challenge that has been brought into sharp focus by recent global events. The PA series is explicitly designed to address this challenge head-on by restoring secure, high-performance, U.S.-based production capabilities. Haase asserted that these domestically produced machines are not only critical to U.S. defense but are also engineered to exceed the capabilities of international printers, providing a decisive technological advantage while simultaneously mitigating supply chain risks. This strategic focus underscores the printer’s role as more than just a piece of equipment; it is a vital tool for national security.

The vision for this transformative technology was articulated by Founder and CEO Bala Anand Jeldi, a veteran with over two decades of experience in additive manufacturing and magnesium alloy applications across the space, defense, and automotive sectors. Jeldi stated that the industry was entering a new era defined by intelligence, reliability, and accountability. He founded Precision Additive to create advanced manufacturing systems that were not only innovative but also dependable enough for the most critical applications where failure is not an option. His notable achievements, including designing the world’s largest 3D printer and developing lightweight components for multiple space missions, informed the creation of the PA-300. Operating from Noblesville, Indiana, the company has positioned itself as both a U.S. Original Equipment Manufacturer (OEM) and a supplier of on-demand production parts. Its overarching mission was to solve longstanding industry challenges related to scalability, certification, and reactive material processing, ultimately re-establishing the U.S. as the global innovation leader in 3D printing.