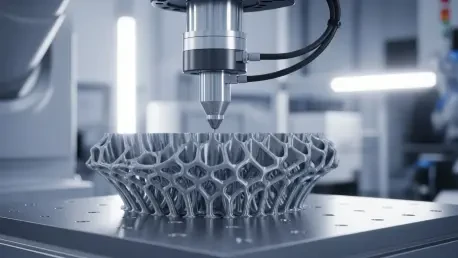

A groundbreaking development at the intersection of material science and artificial intelligence has unveiled a powerful new methodology for designing and analyzing complex materials, promising to overcome one of the most significant hurdles in modern engineering. Recent research illuminates how machine learning (ML) can enhance and streamline the finite element modeling (FEM) of additively manufactured, or 3D-printed, metamaterials. This innovative work, spearheaded by a research team including Meynen, Kolken, and Mulier, represents a monumental leap forward. The fusion of these sophisticated computational techniques unlocks unprecedented levels of efficiency and accuracy, providing deep insights into the behavior of advanced engineered materials that were previously too complex to fully comprehend in a timely manner, thus paving the way for a new generation of high-performance products.

The Computational Bottleneck in Metamaterial Design

The core of this research directly confronts a fundamental challenge in modern material science that has long constrained innovation. Additive manufacturing has revolutionized production, enabling the creation of intricate, complex geometries that were previously impossible to fabricate. This capability has been particularly crucial for the development of metamaterials—materials engineered to possess properties not found in naturally occurring substances, such as a negative refractive index or precisely tailored acoustic and vibrational responses. While their potential is immense, the very complexity that gives these materials their unique capabilities also makes them extraordinarily difficult to model. Traditional methods like Finite Element Modeling, which involves deconstructing a physical object into a vast number of smaller, simpler elements for analysis, become computationally prohibitive. Simulating the behavior of a complex metamaterial structure using FEM can require immense processing power and time.

This computational demand creates a significant bottleneck in the design and innovation cycle, severely limiting the speed at which new materials can be developed and tested. For every minor adjustment to a design, engineers have historically faced the prospect of running another marathon simulation, a process that can stretch for hours or even days. This slow, iterative process not only inflates research and development costs but also discourages the exploration of more radical or unconventional designs that might hold the key to breakthrough performance. The practical limitations of simulation have meant that the vast, promising landscape of metamaterial possibilities has remained largely uncharted. The need for a faster, more intelligent approach to design validation has become increasingly urgent as industries seek to leverage these next-generation materials for competitive advantage, making the computational hurdle a critical barrier to progress.

A Synergistic Approach to Fusing AI and Simulation

The central theme and key finding of the study is the successful integration of machine learning algorithms to overcome this computational hurdle. Instead of replacing the trusted and established FEM process, the ML-assisted approach augments it, creating a synergistic system that is both significantly faster and more insightful. The researchers leveraged supervised learning techniques, a subset of AI where an algorithm is trained on a labeled dataset. In this context, the training data consists of a massive repository of results from previous, computationally intensive FEM simulations. By processing this vast library of information, the ML model learns to identify and understand the intricate, often non-linear relationships between a metamaterial’s geometric structure and its resulting physical properties. This learned intelligence is the cornerstone of the new methodology.

This training enables the model to make highly accurate predictions about the behavior of new, untested designs without the need to run a full, time-consuming FEM simulation from scratch for every single iteration. A crucial advantage highlighted by the research is the ability of machine learning to uncover subtle patterns and correlations within the data that may be overlooked by conventional analysis or even by experienced human engineers. This deep pattern recognition leads to the creation of predictive models with remarkable precision and nuance. The practical result is a dramatic acceleration of the design process, allowing engineers to rapidly evaluate hundreds or thousands of potential designs, discard unpromising candidates, and focus their efforts on the most viable options, thereby fostering a more creative and efficient innovation environment.

The Critical Role of Physical Validation and Industry Impact

A consensus viewpoint emerging from the research is the critical importance of a collaborative, iterative feedback loop between computational modeling and physical experimentation. The study emphasizes that this is not a purely theoretical or simulation-based endeavor. The process involves rigorously validating the ML-driven predictions against real-world data gathered from physical tests of 3D-printed metamaterial samples. The results of these experiments—measuring actual stress, strain, vibration, and other properties—are then systematically fed back into the system. This continuous stream of empirical data serves to constantly refine and fortify the accuracy of the predictive models, creating a powerful, self-improving cycle where the digital twin becomes an ever-more-faithful representation of its physical counterpart. This iterative cycle of simulation, fabrication, testing, and refinement dramatically accelerates the entire design process.

The implications of this research are far-reaching, extending well beyond academic interest and into the realm of tangible industrial application. The ability to rapidly prototype and validate complex material designs stands to reshape key sectors. In the aerospace and automotive industries, for example, this technology can facilitate the creation of lighter, stronger, and more durable components with optimized performance characteristics, such as enhanced shock absorption or vibration damping, leading to safer and more fuel-efficient vehicles. In biomedical engineering, it opens the door to designing patient-specific implants and medical devices with tailored mechanical properties that mimic natural bone or tissue. A key trend identified is the necessity for strong collaboration between academic research institutions and industry partners to ensure these advanced computational tools are effectively translated into practical, real-world applications that can solve pressing engineering challenges.

Unlocking New Possibilities in Customization and Sustainability

Furthermore, the research highlights several additional, significant advantages of this ML-inclusive approach, moving beyond pure performance optimization. One prominent benefit is the capacity for mass personalization on an unprecedented scale. As consumer and industrial demands shift away from one-size-fits-all products and toward customized solutions, the ability to quickly adapt and optimize a material’s design for a specific function becomes invaluable. This technique allows engineers to tailor metamaterials for highly specific applications, from advanced soundproofing panels in architectural design to bespoke protective gear for athletes or first responders. This capability promises to unlock new markets and product categories where tailored material performance is the primary differentiator, offering a distinct competitive edge to early adopters of the technology.

Concurrently, the study champions a move toward more sustainable manufacturing practices, an increasingly critical consideration in global industry. By optimizing material designs for maximum performance and durability while simultaneously minimizing the amount of material used, this approach inherently reduces waste in the production process. The creation of lighter products also contributes directly to greater energy efficiency throughout a product’s lifecycle, particularly in transportation and mobile applications. This dual benefit of reducing upfront material consumption and improving downstream energy use aligns technological advancement with pressing eco-conscious principles. The integration of AI into the design process therefore not only accelerates innovation but also provides a viable pathway toward a more responsible and resource-efficient manufacturing future, demonstrating that performance and sustainability can be complementary goals.

Forging a New Paradigm in Material Engineering

Ultimately, the work presented by Meynen and his colleagues served as a powerful testament to the transformative potential of interdisciplinary research. By merging the sophisticated predictive power of machine learning with the established principles of finite element modeling, they forged a new paradigm for the design and engineering of additively manufactured metamaterials. This advancement heralded a new era defined by unprecedented speed, predictive accuracy, and a deeper commitment to sustainability. As these methods were further refined and the challenges of data standardization were addressed, the boundary between theoretical exploration and tangible application continued to dissolve. This breakthrough paved the way for a future where intelligent, bespoke materials became a cornerstone of modern technology and innovation, fundamentally changing how products were conceived, designed, and manufactured across countless industries.