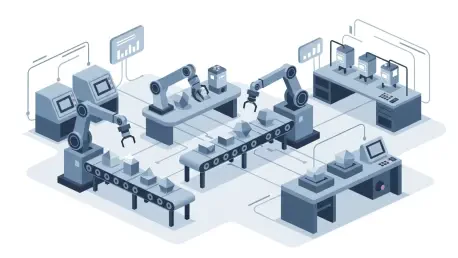

The global industrial control and factory automation market is on an unprecedented trajectory, with projections indicating it will more than double in value, rocketing from USD 226.85 billion in 2025 to an estimated USD 461.36 billion by 2031. This remarkable expansion, representing a compound annual growth rate (CAGR) of 12.56%, underscores a fundamental shift in how modern industries operate. At its core, this sector involves the strategic use of advanced control systems, including sophisticated computers and robotics, alongside cutting-edge information technologies to oversee and manage industrial machinery and processes. The primary objective is to significantly reduce the need for direct human intervention, thereby optimizing workflows, minimizing errors, and boosting overall productivity. This transition is not merely about replacing manual labor; it represents a complete reimagining of the factory floor, where interconnected systems and intelligent devices work in concert to achieve new levels of operational excellence and agility in a rapidly evolving global marketplace.

The Forces Behind Automation’s Surge

Addressing Modern Manufacturing Challenges

The rapid acceleration toward automated solutions is largely a response to two persistent and intertwined pressures facing the industrial world: the relentless demand for greater manufacturing efficiency and a widespread, critical shortage of skilled labor. As global competition intensifies, companies are under constant pressure to produce more, faster, and with fewer defects, all while managing operational costs. Automation provides a direct pathway to achieving these goals by enabling continuous, 24/7 production cycles and ensuring a high degree of precision that is difficult for human workers to sustain. Simultaneously, a growing gap in the skilled labor market means that many manufacturers struggle to fill essential roles, a problem that automation helps mitigate. These factors are further amplified by the broader adoption of Industry 4.0 principles, which champion the creation of “smart factories.” In these environments, automated systems facilitate seamless data exchange between machines and management systems, enhancing production capabilities without the need for extensive manual oversight and paving the way for more resilient and adaptive supply chains.

The Technological Triumvirate

At the heart of this industrial transformation lies a powerful convergence of technologies, with Artificial Intelligence (AI) and Machine Learning (ML) leading the charge. These intelligent systems are proving particularly transformative in the realm of predictive maintenance. Manufacturers are increasingly deploying sophisticated AI-driven algorithms to analyze immense volumes of data streamed from sensors on their machinery. By identifying subtle patterns and anomalies that precede equipment failure, these systems can predict breakdowns with remarkable accuracy. This proactive capability allows companies to schedule maintenance strategically, dramatically reducing costly unplanned downtime and shifting the operational paradigm from reactive repairs to intelligent asset management. A March 2024 report highlighted this trend, noting that 83% of manufacturers had planned to integrate Generative AI into their operations that year. This AI-powered revolution is complemented by other key innovations, including collaborative robots designed to work alongside human employees, the deployment of industrial 5G for ultra-reliable, low-latency communication, and an increasing focus on sustainability through optimized resource consumption.

Navigating the Path to Implementation

Overcoming Financial and Systemic Hurdles

Despite the clear benefits and strong growth forecast, the path to full automation is not without significant obstacles. The most prominent barrier to entry is the substantial initial capital investment required to acquire and implement advanced automation systems. The high cost of industrial robots, sophisticated sensors, and the underlying software infrastructure can be prohibitive, particularly for small and medium-sized enterprises (SMEs) that often operate with tighter budgets. This financial hurdle can create a technology gap, potentially limiting the ability of smaller players to compete with larger corporations that have the resources for large-scale automation projects. However, industry investment has remained robust, signaling a strong belief in the long-term returns. For instance, data from the Association for Advancing Automation revealed that North American companies made significant commitments, purchasing 17,635 robots valued at a combined $1.094 billion in just the first half of 2025. This ongoing investment indicates that while the upfront cost is a major consideration, many organizations view it as a necessary step to secure future competitiveness and operational resilience in an increasingly automated world.

A Look at the Fully Realized Smart Factory

The discourse around industrial automation culminated in a vision where efficiency and intelligence were no longer just goals but foundational principles of manufacturing. It became clear that the integration of AI-powered predictive maintenance did more than prevent downtime; it fundamentally reshaped how organizations managed their physical assets, moving them toward a model of strategic foresight. The deployment of collaborative robots and industrial 5G were not seen as isolated upgrades but as essential components of a deeply interconnected ecosystem. The financial barriers, while significant, were ultimately framed as investments in long-term viability rather than short-term expenses. The trends observed through 2025 and 2026 solidified the understanding that the future of manufacturing was inextricably linked to the intelligent application of technology, paving the way for factories that were not only more productive but also more sustainable and adaptable to global challenges.