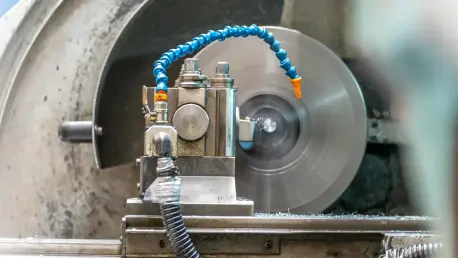

In the realm of precision milling, the integration of artificial intelligence has transformed how tool wear is detected, enhancing the industry’s ability to maintain accuracy, reduce waste, and improve efficiency. The reliance on AI for monitoring and predicting tool wear signifies a pivotal shift in manufacturing processes, allowing real-time analysis through sensors that gather data on vibrations, acoustic emissions, and spindle loads. This data is processed to provide real-time insights that optimize milling operations, extending tool life and maintaining quality standards. The continuous feedback loop created by AI enables operations to proceed without interruptions, ensuring tools remain in optimal conditions. This proactive approach addresses deviations in CNC (Computer Numerical Control) milling operations, where even minute imperfections can impact the precision and functionality of milled parts. With tool wear being a primary consideration in determining product quality, the capacity of AI to preemptively identify wear before it affects performance is indispensable. Manufacturers are increasingly moving from traditional, static methods of tool wear estimation to AI-driven dynamic systems that respond to actual conditions, significantly enhancing production efficiency and quality.

The Influence of AI on Predictive Machining

The influence of AI on predictive machining is a cornerstone of the revolution in precision milling, reshaping both prototype and high-volume production strategies. By incorporating AI into these processes, manufacturers can shift from reactive to proactive workflows, minimizing downtimes while ensuring continuous production. The system’s adaptability to various milling scenarios allows it to accommodate material differences and varying geometric complexities. Machine learning models such as convolutional neural networks (CNNs) and long short-term memory (LSTM) networks revolutionize this process by analyzing intricate datasets to detect wear patterns under different conditions. This approach significantly decreases the occurrence of scrap and the need for rework, which are critical factors in streamlined rapid manufacturing environments. By leveraging AI, manufacturers can ensure the seamless progression of production cycles, avoiding interruptions due to unplanned tool changes and meeting stringent production timelines. AI serves as a foundation for maintaining tool integrity, thereby optimizing the entire production process.

Moreover, predictive engineering through AI extends beyond individual tools and impacts overall system operation. AI algorithms evolve with ongoing data input and manage complex interactions within milling environments. They automatically suggest adjustments, such as alterations in feed rates or tool changes, preventing potential failures before they manifest physically. This leads to enhanced efficiency, particularly in high-speed operations where precision is non-negotiable. In addition, condition-based maintenance facilitated by AI minimizes unnecessary interventions, which is essential given the high costs and time losses associated with unscheduled downtime. As these technologies continue to mature, their integration promises to not only maintain tool precision but also contribute to the optimization of broader machining processes.

The Transition to Condition-Based Tool Management

One of the most profound transitions driven by AI technologies in precision milling is the shift from time-based to condition-based tool management. Traditional methods, which relied on estimated schedules derived from average usage data, are swiftly being replaced by more accurate, AI-driven systems that analyze real-time cutting conditions. These systems utilize a range of complex data inputs, including spindle currents, acoustic outputs, and thermal profiles, allowing for a detailed assessment of tool conditions under varying stress levels. By employing this real-time monitoring approach, manufacturers can significantly reduce waste and enhance the precision of the final product by adapting to the instantaneous state of the tool rather than relying on predetermined schedules.

The use of digital twins in tandem with AI presents another layer of sophistication in the milling arena. Digital twins, which are virtual replicas of physical systems, provide an invaluable tool in analyzing the milling process in a controlled digital environment before any real-world application. This simulation of the manufacturing process, inclusive of elements like stress fields and heat distribution, allows potential issues to be resolved digitally. The ability to identify and mitigate these problems in advance means fewer iterations and considerably reduced time to market. Digital twins thus facilitate rapid prototyping and help manufacturers quickly adapt to design changes or evolving customer requirements without incurring significant delays or costs.

Enhancing Cost-Effectiveness and Quality

AI-driven tool wear detection not only elevates precision but also offers substantial cost benefits by improving production throughput and reducing waste. In precision milling, where even minor errors can cascade into costly defects, early-stage wear detection powered by AI ensures continuous quality control. This aspect is crucial in industries where high stakes demand flawlessness, such as aerospace and medical device manufacturing. AI systems anticipate potential aberrations and execute corrective actions before flaws develop, ensuring the dimensional accuracy and structural integrity of the parts produced. Furthermore, the reduction in material wastage and rework translates into direct financial savings, bolstering the cost-effectiveness of the manufacturing cycle.

AI’s ability to dynamically adjust machining parameters in real-time also translates to improved quality, as it ensures tools operate consistently within their optimal parameters. The precision and predictability afforded by AI are particularly beneficial when milling intricate components that require exact adherence to specified dimensions. The transformation AI brings to traditional manufacturing practices extends beyond the mere technical aspects—enabling organizations to meet ever-increasing demands for shorter production runs and personalized products. As manufacturers continue to adopt AI technologies, they can anticipate sustained improvements in both operational efficiency and product quality, driving growth and competitive advantage in their respective markets.

Future Directions in AI-Integrated Manufacturing

In precision milling, the introduction of artificial intelligence has revolutionized the detection of tool wear, which enhances accuracy, reduces waste, and boosts efficiency. AI’s role in monitoring tool wear marks a crucial shift in manufacturing, with sensors providing real-time data on vibrations, acoustic emissions, and spindle loads. This information is analyzed to deliver immediate insights that refine milling processes, extending the life of tools and maintaining high-quality standards. The AI-driven feedback loop ensures operations are interruption-free, keeping tools in peak condition. This proactive strategy tackles deviations in CNC milling, as even tiny imperfections can affect the precision and functionality of milled components. Since tool wear is a key factor in determining product quality, AI’s ability to detect wear before it impacts performance is vital. Manufacturers are abandoning traditional static methods for AI-powered dynamic systems that adapt to real-time conditions, thereby significantly improving production efficiency and quality.