The American manufacturing sector is confronting a silent crisis that threatens to grind critical industries to a halt, a challenge not of demand, but of a profound and growing scarcity of skilled labor. Projections indicate a staggering deficit of 600,000 welders by 2030, a gap that traditional training programs and recruitment efforts simply cannot fill. This chasm between the need for skilled artisans and their availability puts vital sectors like defense, energy, and infrastructure at significant risk. In the face of this daunting challenge, a new wave of innovation is emerging from the heart of the Midwest. At the forefront is Path Robotics, a Columbus-based company co-founded by CEO Andrew Lonsberry, which is pioneering the application of physical artificial intelligence to the factory floor. By developing truly autonomous systems that can see, understand, and adapt to their environment, the company is not just filling a labor gap but redefining the very nature of industrial manufacturing and offering a tangible solution to one of the nation’s most pressing economic vulnerabilities.

The Technological Breakthrough in Autonomous Welding

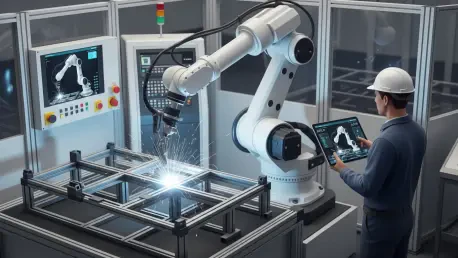

The Power of Physical AI and Obsidian

The core of Path Robotics’ revolutionary approach lies in Obsidian, a proprietary artificial intelligence model meticulously developed and trained specifically for the intricate art of welding. This is not another iteration of conventional automation; it represents a paradigm shift toward what is known as “physical AI.” Unlike traditional industrial robots that follow a rigid, pre-programmed path and require extensive, time-consuming coding for every new task or variation, systems powered by Obsidian possess a form of industrial cognition. They are equipped with advanced sensors that allow them to see and perceive the workpiece in three dimensions, understand its unique geometry, and autonomously generate the optimal weld path in real time. This ability to adapt on the fly eliminates the need for complex programming and fixture requirements, enabling the automation of tasks that were previously considered impossible to automate due to their complexity or variability. This grants manufacturers unprecedented flexibility and agility, allowing them to tackle high-mix, low-volume production runs with the efficiency once reserved for mass production.

The real-world impact of deploying these intelligent welding cells on factory floors has been nothing short of transformative for manufacturers grappling with production bottlenecks. The integration of Obsidian-powered systems has consistently delivered a fourfold increase in productivity, fundamentally altering the economic calculations of fabrication. By automating historically difficult tasks and turning them into reliable, high-volume operations, companies achieve an average cost reduction of 30%. This efficiency gain is crucial for sectors tied directly to national interests, including the construction of AI data center infrastructure, the manufacturing of defense equipment, and the fabrication of components for the energy industry. By providing a scalable and dependable solution, this technology directly strengthens critical U.S. supply chains, reducing reliance on foreign manufacturing and enhancing the nation’s overall industrial competitiveness. The ability to automate complex welding ensures that domestic production can meet surging demand without being constrained by the shrinking pool of available skilled labor.

From Lab Project to a Regional Powerhouse

The ascent of Path Robotics from a nascent university lab project to one of Ohio’s most prominent manufacturing technology firms is a testament to the power of its vision and the urgency of the problem it solves. Under the leadership of Andrew Lonsberry, the company has successfully navigated the challenging path from concept to commercialization, securing over $300 million in funding from major investors. This substantial capital infusion signals strong market confidence in the viability and scalability of its physical AI technology. The company’s success is not just a corporate achievement but a strategic asset for the nation, as it directly supports industries vital to economic and national security. By enabling domestic manufacturers in the defense, energy, and technology sectors to enhance their production capacity and reliability, Path Robotics plays a pivotal role in fortifying the U.S. industrial base against global supply chain disruptions and geopolitical uncertainties, ensuring that critical manufacturing capabilities remain robust and onshore.

Beyond its immediate technological and economic contributions, Path Robotics is spearheading a much broader ambition envisioned by its leadership: to transform Ohio into a global epicenter for physical AI and advanced manufacturing by the year 2050. Lonsberry’s strategy involves fostering a dense and dynamic ecosystem where robotics innovators, AI developers, and heavy industry stalwarts can collaborate and thrive. This vision includes the cultivation of a robust talent pipeline, drawing from the state’s esteemed universities and workforce development programs to create a new generation of high-skill technicians, engineers, and researchers. Path Robotics is already laying the foundation for this future, attracting significant venture capital to the region, creating highly sought-after jobs, and repositioning Ohio not just as a participant but as a national leader in the next wave of industrial innovation. This proactive approach aims to create a self-sustaining cycle of growth that will drive the state’s economy for decades to come.

A Blueprint for the Future of American Manufacturing

The integration of advanced AI and robotics into the welding trade ultimately marked a pivotal turning point for American industry. It became clear that this technological leap was not merely a stopgap for a labor shortage but the foundation of a new industrial paradigm. The success demonstrated by these autonomous systems provided a compelling blueprint for other manufacturing sectors facing similar demographic and skill-based challenges. By proving that complex, variable tasks could be automated intelligently, the initiative inspired a wave of innovation aimed at creating a more resilient, productive, and competitive domestic manufacturing base. The collaborative environment where human expertise guided the deployment of tireless, precise machines established a new standard for productivity and quality, ensuring that the nation’s industrial capacity was prepared for the demands of the future.