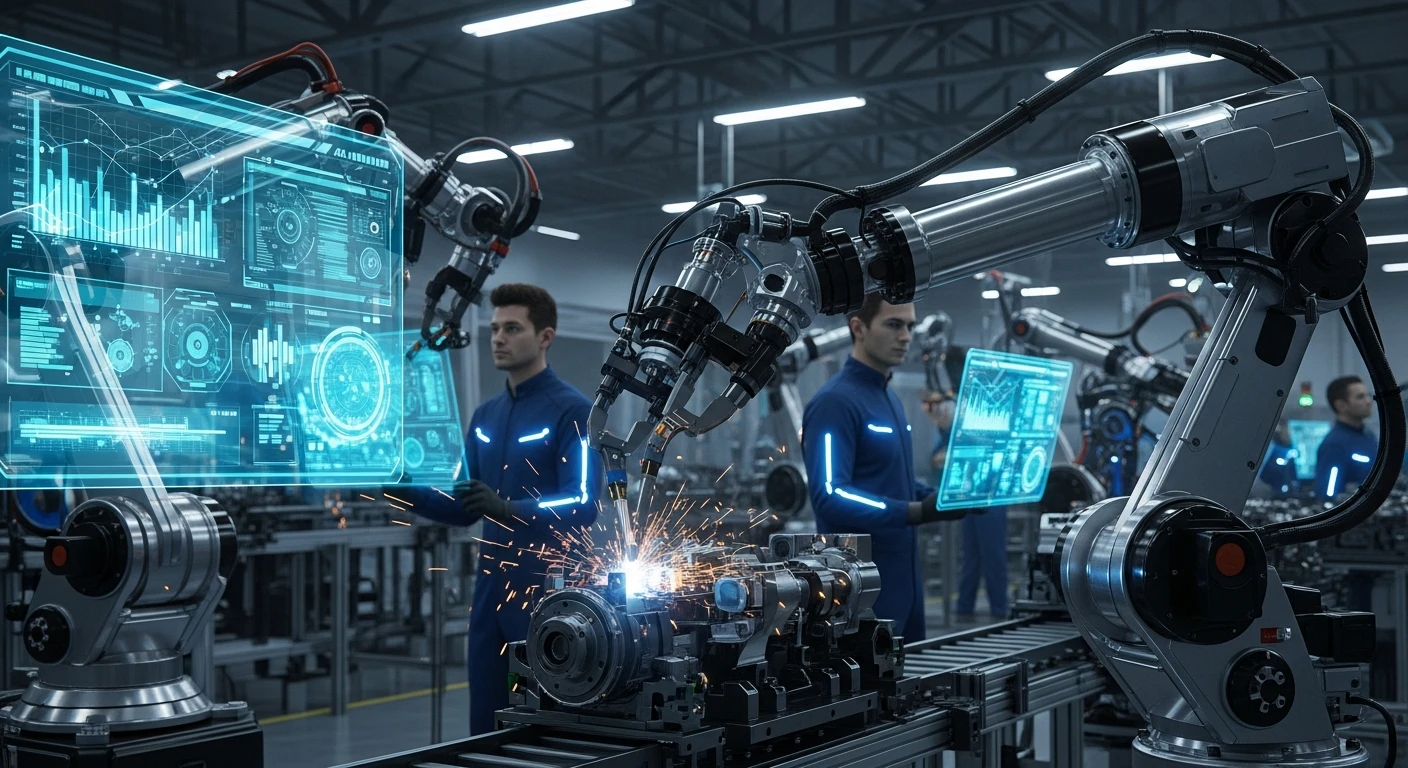

Imagine a factory floor where machines not only assemble products but also predict breakdowns, optimize supply chains, and make decisions without human input. This isn’t science fiction—it’s the near future of manufacturing, powered by artificial intelligence (AI). The industry is at a turning point, with executives channeling massive budgets into AI technologies, driven by the promise of skyrocketing profits and unparalleled efficiency. According to the “Future-Ready Manufacturing Study 2025” by Tata Consultancy Services (TCS) and Amazon Web Services (AWS), a wave of optimism is sweeping through the sector. An impressive 88% of manufacturers foresee at least a 5% boost in operating margins thanks to AI, with many expecting even greater gains in just a few years. This isn’t merely a trend; it’s a bold reimagining of how manufacturing operates, positioning AI as the cornerstone of financial success and operational transformation in an industry hungry for modernization.

Betting Big on AI’s Financial Promise

The manufacturing sector is placing a hefty wager on AI, and the stakes couldn’t be higher. Over half of transformation budgets—51% to be exact—are being poured into AI and autonomous systems over the next two years, far outstripping investments in workforce training or cloud infrastructure. This aggressive financial commitment reflects a deep-seated belief among leaders that AI will be among the top contributors to profit margins by 2026, a sentiment shared by 75% of those surveyed. The potential for quick returns is driving this push, with the industry banking on technology to deliver not just incremental improvements but game-changing results. It’s a high-risk, high-reward strategy, signaling a shift in priorities where digital innovation takes center stage over traditional upgrades, setting the tone for a new era of manufacturing focused on tech-driven prosperity.

However, this financial enthusiasm comes with a sobering reality check. Despite the significant capital flowing into AI, readiness for implementation remains a glaring issue. Only 21% of manufacturers are fully equipped with the clean, unified data necessary to power AI tools effectively. For the majority, fragmented data across multiple plants creates a shaky foundation, limiting the technology’s ability to deliver on its bold promises. This disconnect between investment and preparedness raises critical questions about whether the industry’s optimism is premature. Without addressing these foundational gaps, the hefty budgets allocated to AI risk being squandered, underscoring the need for a more balanced approach that pairs financial ambition with operational groundwork to ensure sustainable success.

Navigating the Operational Minefield

While boardrooms buzz with excitement over AI’s potential, the factory floor tells a grittier story of challenges and hurdles. A major sticking point is integrating AI with aging legacy systems, a barrier flagged by over half of industry respondents. These outdated infrastructures often clash with modern AI tools, creating friction that slows adoption. On top of that, security and governance concerns weigh heavily, with many manufacturers wary of handing over critical operations to autonomous systems that could be vulnerable to breaches. This operational minefield highlights a stark contrast between the gleaming vision of AI-driven efficiency and the messy reality of implementation. Until these systemic issues are tackled, the path to profit through technology remains littered with obstacles that could derail even the most well-funded initiatives.

Moreover, a deeper issue of trust—or the lack thereof—complicates the journey. Despite AI’s knack for predictive insights, many companies still fall back on tried-and-true methods when disruptions strike. A significant number resort to building safety stock or diversifying logistics rather than leaning on digital twins or AI-powered scenario planning to navigate crises. This hesitation to fully embrace digital solutions risks squandering the dynamic efficiencies AI could bring, particularly in areas like inventory optimization. It’s a sign that, for all the hype, faith in technology hasn’t fully taken root on the ground level. Bridging this trust gap is essential if manufacturers hope to move beyond analog safeguards and unlock the true potential of AI to transform how they respond to the unpredictable nature of modern supply chains.

Envisioning Autonomy with Agentic AI

Looking toward the horizon, the emergence of agentic AI—systems capable of making decisions with minimal human oversight—marks a thrilling evolution in manufacturing. By 2028, most industry players anticipate that these AI agents will handle up to half of routine production decisions, with many already automating approvals for standard work orders. This isn’t just about automation; it’s a leap from AI as a helpful sidekick to a decision-making force that can independently steer operations. The focus initially lies on knowledge-intensive tasks like quality control, where productivity gains are already notable, before expanding into more physical roles. This shift paints a picture of factories where technology takes on a life of its own, potentially redefining efficiency in ways previously unimaginable, and setting a new standard for what’s possible in production environments.

In tandem with this technological leap, the impact on the workforce demands careful consideration. Early benefits from AI are expected in cerebral roles, with significant efficiency boosts in areas like IT support and inspections. While the goal is to augment rather than replace human workers, the gradual creep into physical tasks suggests broader changes loom on the horizon. Manufacturers must start rethinking skills development and job roles to align with an AI-driven future. This isn’t merely about keeping up with tech; it’s about ensuring that the human element evolves alongside these autonomous systems. The transition to agentic AI, while promising, brings with it a responsibility to balance innovation with workforce stability, preparing employees for a landscape where technology and human expertise must coexist in harmony to drive the industry forward.

Building Strategic Flexibility for the Future

Beyond the technical and human dimensions, a strategic undercurrent shapes AI adoption in manufacturing. A clear preference for flexibility emerges, with over 60% of companies favoring hybrid or multi-platform approaches to AI deployment. This aversion to vendor lock-in—opting for diverse systems over single-provider solutions—reflects a desire for agility and control in an ever-shifting tech landscape. By spreading their bets across multiple platforms, manufacturers aim to avoid being tethered to one vendor’s ecosystem, ensuring they can pivot as new innovations arise. This pragmatic stance underscores a broader recognition that the journey with AI isn’t a sprint to a single finish line but a long-term play requiring adaptability to navigate the complexities of integration and future advancements.

Furthermore, this focus on flexibility ties into a larger imperative to build resilient systems that can withstand both technological and operational challenges. Industry leaders advocate for creating adaptive ecosystems that prioritize clean data and seamless integration over simply chasing the latest AI models. The emphasis here is on laying a solid groundwork—think unified data structures and robust security protocols—that can support AI’s growth over time. Without this, even the most cutting-edge tools risk faltering under the weight of inconsistent infrastructure. As manufacturers chart their course, this strategic mindset serves as a reminder that lasting success with AI hinges on thoughtful planning rather than blind investment. It’s about crafting a framework today that can evolve with tomorrow’s demands, ensuring the promised profits are not just a fleeting dream but a tangible reality.

Paving the Way for Transformative Success

Reflecting on the strides made, the integration of AI into manufacturing emerged as a defining chapter for the industry, balancing immense potential with sobering challenges. Executives funneled substantial resources into the technology, buoyed by expectations of rapid margin growth. Yet, the path was far from smooth, with data inconsistencies and legacy system struggles testing the limits of readiness. A persistent reliance on traditional methods over digital solutions revealed a trust gap that needed closing. Despite these hurdles, the shift toward agentic AI hinted at a future where autonomous decisions reshaped operations. Looking ahead, the focus must pivot to actionable steps: prioritizing data modernization, fostering trust through gradual autonomy, and maintaining strategic flexibility with diverse platforms. These efforts promise to turn optimism into results, ensuring that the industry’s bold bet on AI paid off in transformative, lasting ways.