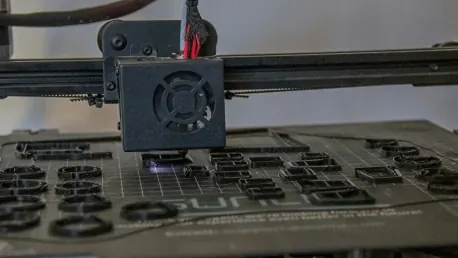

Additive manufacturing (AM), also known as 3D printing, is poised to undergo a significant transformation with the integration of artificial intelligence (AI). This synergy promises not only to address existing manufacturing inefficiencies but also to advance sustainable, low-carbon production methods. By leveraging AI, the AM industry can achieve new levels of precision, efficiency, and environmental responsibility, aligning with modern sustainability goals and the pursuit of a circular economy.

Enhancing Manufacturing Efficiency

The Need for Agile Production

The traditional manufacturing landscape is riddled with inefficiencies that hinder progress towards sustainability. Classic methods struggle with high costs, long lead times, and a dependency on extensive global supply chains. In contrast, there’s an increasing demand for agile, small-batch production processes that are both cost-effective and environmentally friendly. AI-driven additive manufacturing offers a solution, enabling production that is flexible and localized.

AI can dramatically reduce lead times and costs associated with traditional manufacturing by enabling on-demand production. Small-batch and customized production have become viable, allowing manufacturers to respond quickly to market demands without overproducing. This flexibility is crucial in an era where consumer preferences rapidly change and supply chain disruptions are more frequent. AI’s ability to optimize production schedules and resource allocation further enhances efficiency, making small-scale, localized production both practical and economically viable.

Optimizing Design-to-Production Pipelines

One of the primary challenges in AM is the iterative process between design and production, which often involves substantial trial-and-error to achieve the desired quality. AI can revolutionize this aspect by streamlining the design-to-production pipeline. With AI tools capable of predicting print failures and automating slicer settings, designers can significantly reduce the trial-and-error cycle. This results in faster production times and enhanced reliability, ultimately leading to more scalable manufacturing processes.

AI’s predictive capabilities extend to identifying potential structural weaknesses in designs before printing begins. By analyzing vast amounts of data from previous print jobs, AI can suggest modifications to improve strength and reduce material usage. This not only improves the quality of the final product but also minimizes waste, an essential factor in sustainable manufacturing. Additionally, automating slicer settings through AI ensures that each print job is optimized for material efficiency and reduces human error, making the process more consistent and reliable.

Advancing Sustainability Goals

Circular Material Flows

AI-driven additive manufacturing is instrumental in advancing sustainability targets by facilitating circular material flows. Technologies that support the use of recycled or renewable feedstock, alongside the capability to reprint at the end of a product’s life, embody practical approaches to sustainable manufacturing. Companies like Batch.Works are pioneering this space by integrating AI with a focus on circularity, demonstrating how these innovations can reduce waste and promote eco-friendly production.

The use of recycled materials in AM is particularly noteworthy, as it directly addresses the issue of plastic waste. By feeding recycled polymers into the production process, manufacturers can create high-quality products while reducing dependence on virgin materials. AI’s ability to ensure the consistent quality of these recycled materials is critical, as variability can lead to defects and inefficiencies. Furthermore, the potential for reprinting products at the end of their lifecycle means that materials can be continuously reused, significantly reducing overall waste and environmental impact.

Institutional Support for Low-Carbon Solutions

Government initiatives are playing a crucial role in fostering an environment conducive to sustainable practices. Programs such as the UK’s Circular Taskforce and Extended Producer Responsibility rules are pushing producers towards accountability and higher plastic recycling rates. These institutional efforts support and enhance the adoption of AI-driven AM, creating a favorable landscape for these technologies to thrive and contribute to global sustainability efforts.

Such policies not only incentivize manufacturers to adopt more sustainable practices but also provide the regulatory framework needed to standardize these efforts. By holding producers accountable for the lifecycle impact of their products, governments are driving the shift towards a circular economy. This external pressure, combined with the internal efficiency gains provided by AI, positions AM companies as leaders in sustainable manufacturing. The collaborative effort between institutions and industry pioneers like Batch.Works highlights the potential for significant environmental advancements through AI-driven technologies.

Paving the Way for Localized Production

AI-Driven Microfactories

The concept of local, on-demand production is gaining traction, with AI and AM technologies leading the charge. By employing AI to continuously optimize printing parameters and material flows, the industry is moving towards the establishment of local microfactories. These facilities can produce parts on-demand with near-zero waste, showcasing a model that not only reduces dependency on global supply chains but also enhances local economic resilience.

Microfactories represent a paradigm shift from centralized, large-scale manufacturing to distributed, localized production. This shift is empowered by AI’s ability to manage complex production workflows efficiently. Localized production reduces the carbon footprint associated with shipping and logistics, further aligning with sustainability goals. Additionally, microfactories can spur local economic development by creating jobs and fostering innovation within communities. The adaptability of these facilities allows for rapid adjustments to changing market demands, ensuring that production remains efficient and relevant.

Scaling Sustainable Manufacturing

Additive manufacturing (AM), commonly called 3D printing, is set for a major transformation with the integration of artificial intelligence (AI). This combination holds the promise of resolving current inefficiencies in manufacturing and promoting sustainable, low-carbon production techniques. With the incorporation of AI, the AM sector can reach unprecedented levels of precision and efficiency, reducing waste and conserving resources. This aligns with contemporary sustainability objectives and supports the shift towards a circular economy, where materials are reused and recycled rather than discarded. The fusion of AI and 3D printing not only enhances productivity but also underscores environmental responsibility, making manufacturing practices greener and more sustainable. As industries increasingly focus on reducing carbon footprints, the AI-driven advancements in additive manufacturing could play a vital role in achieving these goals, thus paving the way for a more sustainable future in production.