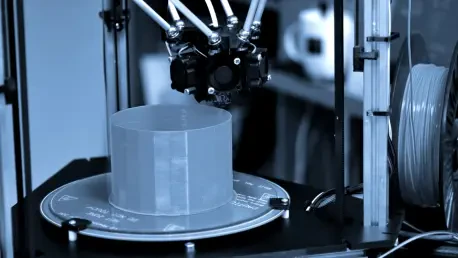

In recent years, the 3D printing industry has sought innovative methods to embrace sustainability, and a pioneering research team has taken a significant step in this direction. Focusing on the composition of 3D printing resins, researchers are developing plant-based alternatives derived from succinic acid, malic acid, and tartaric acid, substances commonly found in everyday foods like corn and broccoli. By pivoting away from fossil fuel-based resins, this initiative seeks to meet the growing global demand for eco-friendly solutions, turning an environmentally taxing industry on its head. The challenge lies in producing high-performance materials that do not compromise on industrial standards, a task that requires resins to be liquid, devoid of solvents, and exhibit rapid polymerization kinetics for broad application.

The Shift to Renewable Resources

Developing Plant-Based Polymeric Resins

The exploration of plant-based materials in the formulation of polymeric resins marks a continuous journey toward sustainable manufacturing. Under the guidance of Elaine Armelin at Universitat Politècnica de Catalunya – BarcelonaTech, the research delves into using biogenic acids. These acids serve as fundamental building blocks for creating innovative resin solutions. This shift aims not only to reduce carbon footprints but also to develop a viable alternative that maintains the functionality and efficiency required in diverse industrial sectors. By addressing these challenges, the team is actively contributing to setting a new standard for materials in additive manufacturing. Their efforts form part of a broader Base-3D project that strategically targets enhancing the maturity and sustainability of this technology, seeking to embed these novel materials into sectors as varied as operating theaters, companies, and educational institutions. This demonstrates a significant transformation in how industries perceive and adapt to sustainable practices.

Industrial Viability and Challenges

The journey from concept to execution involves overcoming several key challenges, primarily ensuring the resin’s properties align with industrial needs. Sustainable solutions must demonstrate robust practical application: possessing the necessary fluid dynamics, needing no solvent additives, and achieving rapid curing properties. Working under Fernando Bravo’s supervision at the Institute of Chemical Research of Catalonia, teams aim to meet these stringent criteria through concerted research and development efforts. Addressing these challenges promises a significant leap in agricultural waste utilization, potentially turning organic waste into valuable manufacturing inputs. The successful integration of these materials would not only enhance the ecological benefits of additive manufacturing but also broaden the scope of what is feasible within the industry.

A Movement Toward Sustainability

Base-3D Project and Its Implications

Embedded within the Base-3D project, this initiative truly exemplifies the collaborative efforts seeking sustainable 3D printing solutions. With the underpinning ideology of enhancing technology maturity, this project champions the creation and integration of eco-friendly practices across various regional sectors in Catalonia. As the development and adoption of these innovative materials progress, the project represents a visionary endeavor that aligns technological advancement with environmental responsibility. Its implications spread across broad disciplines, potentially revolutionizing the fields of medicine, education, and beyond through the introduction of customizable, sustainable material solutions. This progressive transformation echoes a broader shift in how industries operate, aligning business objectives with ethical and environmental goals, showcasing a promising horizon for future sustainable technologies.

Broader Applications of Soft Biopolymers

Elsewhere within the research community, a growing interest in the potential applications of soft biopolymers further expands the outlook of sustainable 3D printing. Materials such as alginate and chitosan are gaining traction due to their versatility and biodegradability. These substances could revolutionize numerous fields, from enhancing soil quality in agriculture to developing innovative desalination cells for water purification. Their use exemplifies the overarching commitment to sustainability reflected in the scientific community’s endeavors. By extending the application of these materials beyond traditional sectors, researchers are paving the way for widespread environmental improvements, underscoring the ethical mandate of modern science. This exploration into diverse application areas speaks to a holistic approach that seeks not just innovative solutions but those that resonate with multi-sectoral adaptation.

Future Considerations in 3D Printing Materials

Emerging Trends and Industry Impact

As the 3D printing industry continues to evolve, the transition towards sustainable materials represents an emerging trend with vast potential implications. The focus on reducing dependency on fossil fuels and minimizing environmental impacts is gaining momentum. As these plant-based solutions become more industrially viable, companies are likely to integrate them into standard production practices. This paradigm shift can lead to wider acceptance and adoption of green technologies, reflecting a significant transformation of both manufacturing processes and end-user expectations. As organizations recognize the long-term benefits of sustainability, from cost savings to enhanced brand loyalty and environmental compliance, the impetus toward greener practices is likely to drive continued innovation and investment in this domain.

Strategic Advancements and Opportunities

The exploration of plant-based materials in the creation of polymeric resins is an ongoing journey towards sustainable manufacturing. Under Elaine Armelin’s leadership at the Universitat Politècnica de Catalunya – BarcelonaTech, researchers are investigating the use of biogenic acids as core components for innovative resin solutions. This transition aims to not only minimize carbon emissions but also to offer an effective alternative that retains the required functionality and efficiency for various industries. By addressing these complex challenges, the research team is helping to establish a new benchmark for materials in additive manufacturing. Their work is part of a larger initiative, the Base-3D project, which focuses on advancing the development and sustainability of this technology. The goal is to integrate these new materials into a diverse range of sectors, including healthcare, business, and education. This marks a significant shift in how industries understand and adopt sustainable practices, paving the way for a more eco-conscious future.