The groundbreaking success of CAR T cell therapies in treating once-intractable cancers has created a profound and paradoxical challenge for the biopharmaceutical industry: as clinical victories mount, the ability to manufacture these personalized medicines at scale is falling dangerously behind patient demand. This critical manufacturing bottleneck, characterized by complex, labor-intensive, and costly processes, threatens to limit the reach of life-saving treatments. In a significant move to address this impending crisis, Autolus Therapeutics and Cellares have forged a strategic partnership to evaluate a next-generation automated manufacturing platform. This collaboration is not merely an operational upgrade but a proactive effort to build a scalable, sustainable, and capital-efficient infrastructure capable of meeting the anticipated surge in demand for Autolus’s flagship therapy, ensuring that scientific breakthroughs can translate into widespread patient access without crippling logistical hurdles. The outcome of this evaluation could set a new standard for the entire cell therapy sector.

Addressing the Production Bottleneck

The Growing Demand for Aucatzyl

Autolus Therapeutics finds itself at a pivotal juncture where clinical success is driving an urgent need for manufacturing innovation. The company’s leading CAR T cell therapy, Aucatzyl (obecabtagene autoleucel), has already secured regulatory approval for adults with a specific type of acute lymphoblastic leukemia, marking a major therapeutic advance. However, the potential patient population for Aucatzyl is poised for exponential growth. Autolus is actively pursuing clinical studies to expand its application to pediatric patients, a development that would significantly increase the number of eligible individuals. Furthermore, the company is exploring the therapy’s potential in treating autoimmune diseases like lupus, an indication that could open up an entirely new and vast market. This expanding pipeline, while clinically promising, places immense pressure on the company’s existing manufacturing capabilities. The current facility in the United Kingdom, while state-of-the-art, was not designed to support the global demand that could arise from multiple approved indications, creating a clear and present need for a more scalable and flexible production solution.

The Limitations of Conventional Manufacturing

The fundamental challenge in scaling CAR T therapies lies in the autologous manufacturing process itself, which is inherently patient-specific and traditionally manual. Conventional methods require highly trained technicians to perform a series of intricate steps in sterile cleanroom environments. This process involves isolating a patient’s T cells, genetically engineering them to recognize and attack cancer cells, and then expanding them into a sufficient dose for reinfusion. Each step is prone to human error and variability, leading to a significant risk of batch failure, which is devastating for critically ill patients with limited time. Moreover, this manual approach is incredibly resource-intensive, demanding substantial cleanroom space, specialized equipment, and a large, skilled workforce for each patient batch. Scaling up this model simply means building more of these expensive facilities and hiring more personnel, a linear and economically unsustainable strategy. This approach does not offer the economies of scale seen in traditional drug manufacturing, making it a major barrier to reducing costs and broadening patient access.

Innovating for Scalable Production

The Cell Shuttle’s Automated Approach

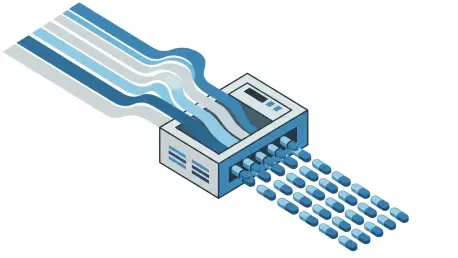

Cellares offers a transformative solution to the industry’s scaling dilemma with its Cell Shuttle platform, a technology that reimagines the CAR T manufacturing workflow. The Cell Shuttle is a fully automated, closed-system platform that consolidates the entire multi-day manufacturing process into a single, high-capacity instrument. This “factory-in-a-box” concept utilizes a sterile, single-use cartridge for each patient, minimizing the risk of cross-contamination and human error that plagues manual methods. One of the platform’s most significant features is its parallel processing capability, which allows a single unit to manufacture up to 16 distinct patient batches simultaneously. Cellares claims this can deliver a tenfold increase in manufacturing throughput compared to a conventional facility of similar size. The system is further enhanced by its integration with the “Cell Q” platform, which automates quality control testing and maintains comprehensive digital batch records, streamlining compliance and release processes. Crucially, the Cell Shuttle platform has already received the FDA’s Advanced Manufacturing Technology designation, which can help expedite regulatory reviews for therapies produced using the system.

A Capital-Efficient Path to Expansion

The partnership between Autolus and Cellares is rooted in a shared strategic vision that prioritizes both scalability and economic viability. For Autolus, this collaboration represents what its CEO, Christian Itin, describes as a “capital-efficient” pathway to expanding its global manufacturing footprint. Rather than investing hundreds of millions of dollars in building new traditional cleanroom facilities, Autolus can potentially leverage Cellares’ technology to increase its production capacity in a more modular and less capital-intensive manner. This approach allows the company to flexibly respond to market demand as new indications for Aucatzyl are approved. From the perspective of Cellares CEO Fabian Gerlinghaus, the company’s technology is positioned not merely as a piece of equipment but as a global infrastructure solution. The goal is to extend Autolus’s foundational manufacturing capabilities, creating a distributed and standardized production network. Ultimately, this strategic alignment aims to solve the core challenge of the cell therapy industry: reducing the high cost and failure rates associated with manufacturing to make these powerful therapies more accessible and affordable for patients worldwide.

Pioneering a New Manufacturing Paradigm

The alliance between Autolus and Cellares marked a pivotal moment in the evolution of cell therapy commercialization. It represented a strategic shift away from a reactive approach to manufacturing and toward a proactive, technology-driven model designed for global scale. This partnership established a clear blueprint for how biopharmaceutical companies could address the logistical and economic challenges that often followed significant clinical breakthroughs. By embracing automation and a capital-efficient expansion strategy, the two companies laid the groundwork for a more sustainable and accessible future for personalized medicine. The collaboration signaled a maturation of the industry, where manufacturing strategy was finally recognized as being as critical to a therapy’s success as the clinical science behind it. This forward-thinking approach provided a compelling answer to the production scalability problem that had long threatened to limit the transformative potential of CAR T cell therapies.