Artificial Intelligence (AI) has revolutionized the manufacturing sector by drastically transforming operations and improving efficiencies. Today, manufacturers are leveraging AI technologies to advance predictive maintenance, enhance supply chain performance, and refine product quality. However, this rapid integration of AI also presents significant risks, particularly in security and regulatory compliance. The purpose of this roundup is to explore diverse perspectives from industry experts on the balance between AI’s innovative potential and its associated risks in manufacturing.

Navigating the Landscape of AI in Manufacturing

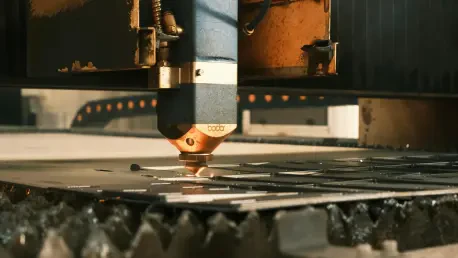

Observers have traced the evolution of AI in manufacturing, highlighting its profound impact on factory modernization and industry growth. AI-equipped systems optimize production processes and have become indispensable for maintaining competitive advantage. Yet, there remains a critical need to balance AI’s capabilities against the risk factors to optimize safety and efficiency.

Experts underline AI’s role as a driving force in modernizing manufacturing facilities, paving the way for industrial growth. Riding on the wave of digital transformation, these technologies have improved operational productivity and reduced costs. Despite these advantages, a balanced approach is vital to manage the promises and pitfalls of AI.

Unpacking the Promise: AI as a Catalyst for Manufacturing Excellence

Industry leaders recognize the transformative potential of AI-driven analytics, which foster substantial improvements in predictive maintenance, supply chain orchestration, and overall product quality. Reports reveal that these advancements translate into tangible outcomes, enhancing operational efficiencies and cost-effectiveness. However, seamlessly integrating AI into existing structures remains a challenge due to potential disruptions and compatibility issues.

Different viewpoints highlight how AI contributes to manufacturing excellence by boosting performance metrics and ensuring precise control over production processes. While multiple reports detail AI’s impact in reducing downtime and enhancing responsiveness, adapting these technologies to incumbent systems presents ongoing hurdles. Experts advise careful planning to mitigate integration challenges.

Precarious Pathways: The Risks Looming Large Over AI Utilization

Security experts emphasize AI’s vulnerability to cyberattacks that compromise data integrity and operational continuity. Past incidents in various industries have exposed weaknesses in AI systems, stressing the need to fortify cyber defenses. Additionally, inadequate governance can lead to serious data breaches and operational issues, posing significant threats to business stability.

The repercussions of insufficient AI governance can be severe, leading to data breaches with long-lasting effects. The necessity for stringent security measures is echoed by experts who cite examples of operational setbacks resulting from governance lapses. Manufacturers must reconcile these risks to harness AI’s potential fully without compromising security.

Changing Tides: Adapting to AI Regulation and Compliance

Regulatory changes now demand greater AI transparency and accountability, affecting how manufacturers implement these technologies. Worldwide, regional compliance requirements are evolving, influencing global trade dynamics and prompting manufacturers to adopt new compliance frameworks suited to varied regulatory landscapes.

With regulators enforcing AI transparency, regions are setting divergent standards influencing the manufacturing ecosystem. Existing compliance frameworks require adaptation to align with newly emerging regulations. Experts foresee these changes significantly impacting global operations, necessitating strategic adjustments by manufacturers to maintain compliance without stifling innovation.

Future Horizons: Innovative Strategies for AI Risk Mitigation

Innovative risk mitigation strategies, such as centralized governance and automated monitoring, are being adopted by manufacturers to secure AI investments. Insights suggest that adopting structured governance methods and integrating comprehensive oversight tools are crucial for maintaining compliance and competitive edge.

Experts recommend centralized risk management as crucial for regulating AI deployment, integrating monitoring systems, and safeguarding data integrity. Adopting structured oversight mechanisms is deemed essential for reducing vulnerability and ensuring a seamless balance between innovation and regulation.

Strategic Imperatives for a Balanced AI Adoption

Manufacturers are urged to adopt robust governance models to secure effective AI integration. Industry best practices advocate continuous data validation and proactive cybersecurity protocols to protect against potential threats. These strategies are indispensable in navigating the complex landscape of AI adoption within manufacturing.

To ensure balanced AI adoption, experts highlight the significance of implementing strong governance structures, emphasizing ongoing model evaluation and data scrutiny. Proactive security measures, including regular audits and vulnerability assessments, are key strategies recommended for efficient risk mitigation.

Concluding Reflections on AI’s Role in Manufacturing’s Evolution

The article consolidated various insights into the transformative era of AI in manufacturing, underscoring its dual focus on innovation and risk management. Discussions among industry experts suggested that ongoing discourse and strategic adjustments were shaping the competitive landscape. As manufacturers evaluated AI investments, they considered not only the modernization potential it delivered but also the security and compliance measures required to protect business interests. By acknowledging these factors, manufacturers positioned themselves to make informed decisions regarding AI integration, ensuring that advancements continued to serve as an enabler of growth and efficiency.