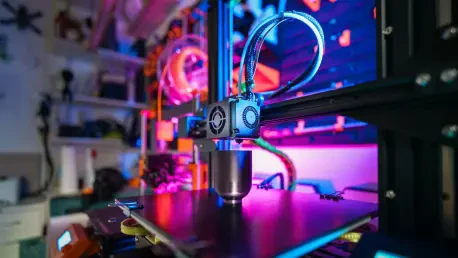

Imagine a future where the smallest creatures in nature guide the most cutting-edge human innovations, where the humble honeybee becomes a mentor for revolutionizing technology. A groundbreaking study from the University of Colorado Boulder has unveiled an astonishing connection between the hive-building prowess of bees and the potential to transform 3D printing. These tiny architects, renowned for crafting intricate honeycomb structures, adapt to imperfect environments with a finesse that could redefine additive manufacturing. By unraveling the secrets of their collective problem-solving and resource efficiency, researchers are finding ways to make 3D printing not only more precise but also far more sustainable. This discovery bridges the gap between biology and engineering, offering a glimpse into how nature’s time-tested strategies might solve modern industrial challenges. The implications are vast, promising advancements that could ripple across multiple fields with a focus on adaptability and minimal waste.

Unveiling Nature’s Blueprint: Honeybees as Master Builders

Honeybees have long captivated scientists with their ability to construct complex hives without a single leader or centralized plan, relying instead on a remarkable system of distributed decision-making. Each bee contributes tiny amounts of wax, responding to immediate surroundings rather than following a predefined blueprint. This results in a unified structure that stands as a testament to the power of localized, coordinated efforts. Described by researchers as a “distributed construction crew,” this approach challenges conventional engineering models that often depend on top-down control. The CU Boulder study highlights how such a decentralized method could inspire new frameworks in technology, where independent actions at a micro level create robust outcomes at a macro scale. For 3D printing, this suggests a shift toward systems that prioritize real-time adaptability over rigid programming, potentially reducing errors during production.

Beyond their collaborative genius, honeybees demonstrate an innate understanding of structural efficiency that has evolved over millions of years to meet the demands of survival. Their preference for hexagonal cells in hive construction is no accident; it’s a design that maximizes storage space while minimizing the use of precious materials. When faced with less-than-ideal conditions, such as uneven surfaces or irregular frames, bees adjust their building patterns with astonishing precision. This adaptability ensures the hive remains functional without squandering resources, a principle that resonates deeply with the goals of modern manufacturing. In the context of 3D printing, emulating this behavior could mean developing machines capable of altering print patterns on the fly to accommodate flaws or unexpected variables. Such innovation would mark a significant leap toward creating technology that mirrors nature’s balance of form and function.

Resource Scarcity: Efficiency Lessons from the Hive

One of the most striking aspects of honeybee behavior is their ability to operate under severe resource constraints, a challenge that mirrors many issues in industrial design today. Producing wax is an energy-intensive process for bees, requiring approximately eight ounces of honey to yield just one ounce of wax. This scarcity drives their architectural choices, leading to the iconic hexagonal structure that optimizes space with minimal material. The CU Boulder research underscores how bees’ frugality could inform 3D printing practices, where material waste remains a persistent problem. By adopting similar principles of efficiency, manufacturers could reduce excess use of raw materials, cutting costs and environmental impact. This natural lesson in thrift reveals how limitations can spur creativity, pushing technology to achieve more with less in a world increasingly focused on sustainability.

Another critical insight from studying bees is their knack for maintaining efficiency even when conditions are far from ideal, a scenario often encountered in manufacturing environments. When building on irregular surfaces like curved tree hollows or uneven foundations, bees modify their approach without compromising the hive’s integrity. They might merge cells or adjust angles to reclaim usable space, ensuring no effort or resource goes to waste. For 3D printing, this adaptability offers a powerful model for handling defects or inconsistencies during production. Imagine printers that detect and correct errors mid-process, much like bees adapt to flawed starting points. Such technology could revolutionize industries by minimizing downtime and enhancing the reliability of printed structures, drawing directly from the resource-conscious mindset of these tiny insects.

Adapting to Challenges: Bees’ Innovative Construction Tactics

Delving deeper into the CU Boulder study, it becomes clear that honeybees possess a versatile toolkit for tackling structural challenges, particularly when working with imperfect foundations. Researchers provided bees with 3D-printed comb bases of varying hexagon sizes—some smaller, some larger than average—and observed their responses. On smaller guides, bees merged cells to recover functional space, while on larger ones, they tilted walls or layered transitional structures to revert to preferred dimensions. These adjustments ensure the hive remains operational regardless of initial setbacks. This flexibility is a goldmine for 3D printing, where irregularities in materials or equipment often lead to costly errors. By mimicking these tactics, printing systems could dynamically adjust to unexpected issues, ensuring consistent quality in the final product.

The significance of these adaptive strategies extends beyond mere problem-solving; it reflects a profound resilience that could redefine how technology handles complexity. Unlike human-engineered systems that often require extensive recalibration or manual intervention to address flaws, bees operate on simple, local rules that scale effortlessly across the colony. Each bee’s small decision contributes to a larger, harmonious outcome, a process that avoids the bottlenecks of centralized control. Applying this to 3D printing could mean developing algorithms that allow printers to make micro-adjustments during the layering process, responding to defects as they arise. This approach would not only improve efficiency but also open doors to printing on non-standard surfaces or with unconventional materials, expanding the scope of what additive manufacturing can achieve in practical settings.

From Hive to High-Tech: Biomimicry’s Role in Innovation

The concept of biomimicry—drawing inspiration from nature to solve human problems—takes center stage in translating honeybee strategies into tangible technological advancements. The CU Boulder team envisions 3D printers that emulate bees’ local, rule-based methods, adjusting layer orientation or cell size in real time to address irregularities. Such adaptability could significantly reduce material waste and enhance the structural integrity of printed objects. Moreover, the implications stretch beyond 3D printing into fields like aerospace, where lightweight yet strong honeycomb-inspired designs are already prized, and architecture, where adaptive construction could optimize building on uneven terrain. This cross-disciplinary potential underscores how nature’s solutions, honed over millennia, can address modern challenges with elegance and efficiency.

Further exploration of biomimicry reveals how deeply honeybee principles could reshape industrial paradigms, particularly in fostering sustainability. The ability of bees to build resilient structures with minimal resources aligns closely with global efforts to create greener technologies. In 3D printing, adopting these natural tactics could lead to processes that consume less energy and produce less scrap, aligning with environmental goals. Additionally, industries that rely on precision and durability, such as medical device manufacturing, could benefit from printers that adapt to minor flaws without compromising output quality. The vision is clear: by looking to the hive, engineers can craft systems that not only perform better but also contribute to a more sustainable future, proving that even the smallest creatures can inspire monumental shifts in human innovation.

Shaping Tomorrow: Decentralized Thinking in Technology

Traditional engineering often hinges on centralized plans and strict protocols, a stark contrast to the fluid, decentralized approach of honeybees that could herald a new era for technology. Bees rely on individual actions guided by simple rules, creating resilient structures that adapt to imperfections without a top-down directive. This distributed model offers a compelling alternative for 3D printing, where current systems can falter when faced with unexpected variables. By integrating decentralized problem-solving, printers could respond to issues in real time, adjusting parameters without halting production. This shift in mindset challenges long-held assumptions about control in manufacturing, suggesting that flexibility at the local level might yield stronger, more reliable results across diverse applications.

Reflecting on the journey from hive to high-tech, the insights gained from studying honeybees in past research have already sparked discussions about reimagining industrial processes. The decentralized strategies that enabled bees to thrive under constraints were meticulously analyzed, paving the way for concepts that prioritize adaptability over rigid structure. As technology continues to evolve, the next steps involve developing prototypes that incorporate these natural principles, testing their efficacy in real-world scenarios. Collaborative efforts between biologists and engineers will be crucial to refine these ideas, ensuring that the lessons from nature translate effectively into practical solutions. The path forward lies in embracing this bio-inspired innovation, exploring how distributed thinking can address modern manufacturing challenges with the same ingenuity that bees applied to their hives centuries ago.