The combat readiness of the United States Army’s most advanced ground vehicles is currently dictated by a complex web of global logistics, often stretching thousands of miles across contested territories. This intricate system, while a marvel of modern planning, also represents a significant vulnerability. When a single component fails, a multi-million dollar asset can be rendered inert, not by enemy fire, but by the lengthy and fragile process of acquiring a replacement. This challenge has prompted military leaders to explore a radical new solution: manufacturing critical parts directly where they are needed.

At the heart of this strategic shift is a Cooperative Research & Development Agreement (CRADA) between the US Army DEVCOM Ground Vehicle Systems Center (GVSC) and California-based Velo3D. The collaboration aims to leverage advanced additive manufacturing, or 3D printing, to build a more resilient and responsive supply chain. By qualifying 3D-printed metal parts for ground vehicles, the Army is taking a decisive step toward mitigating the risks of traditional procurement and ensuring its forces remain at peak operational readiness.

When a Multi-Ton Combat Vehicle is Sidelined by a Single Missing Part

The operational tempo of modern military ground forces is relentless, placing immense strain on every component of a combat vehicle. From engine brackets to hydraulic fittings, the failure of even a minor part can have a disproportionate impact, effectively sidelining an entire vehicle. This scenario is not hypothetical; it is a recurring challenge that maintenance crews face, where a simple repair is delayed for weeks or months while waiting for a replacement to navigate a complex and often backlogged supply network.

This logistical delay translates directly into a reduction in combat effectiveness. A vehicle awaiting a part cannot perform its mission, creating a capability gap that can have tactical consequences. The problem is compounded for older systems, where original parts may be out of production, forcing the military to engage in costly and time-consuming reverse engineering or sourcing from a limited pool of suppliers. The result is a fleet whose readiness is dictated not just by its design but by the availability of its simplest components.

The Battlefield’s Weakest Link: A Traditional Parts Pipeline

The conventional military supply chain is a system built on forecasting, warehousing, and transportation. While effective in peacetime, it becomes a liability in a contested environment. Long supply lines are vulnerable to disruption, and massive, centralized warehouses present high-value targets. The reliance on parts manufactured overseas, often with subtractive methods that require significant tooling and setup time, introduces long lead times that cannot adapt to the urgent demands of a dynamic battlefield.

This traditional model creates a pipeline that is both slow and brittle. When demand for a specific component surges unexpectedly, the system struggles to respond, leading to critical shortages at the point of need. The Army’s inventory is vast, but it cannot possibly stockpile every conceivable part for every vehicle. This inherent limitation means that readiness is perpetually at risk, tethered to a supply chain that was not designed for the speed and uncertainty of modern conflict.

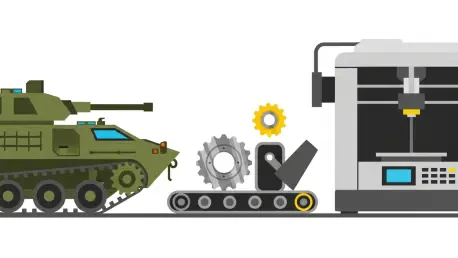

A New Arsenal: Forging Parts on Demand with Additive Manufacturing

To sever this dependency on a fragile supply chain, the Army is turning to additive manufacturing. The partnership with Velo3D focuses on using its Laser Powder-Bed Fusion (PBF-LB) technology to print mission-critical metal parts on demand. Under the CRADA, Velo3D’s Rapid Production Solution will be used to fabricate and test alternative components, moving them through a rigorous qualification process managed by GVSC to ensure they meet or exceed the performance of their traditionally manufactured counterparts.

This initiative is underpinned by Velo3D’s domestically developed and assembled Sapphire family of machines. These systems can produce large-format parts up to 600mm in diameter and one meter high, offering the scale needed for many ground vehicle components. Crucially, the technology provides high-fidelity, repeatable manufacturing with in-situ process monitoring to guarantee quality control. Furthermore, the systems comply with Department of Defense cybersecurity standards, allowing them to be securely connected to military networks for the direct transmission of digital part files.

Voices from the Front Lines of Innovation: Leadership Endorses the Mission

The strategic importance of this collaboration is underscored by leadership from both organizations. Brandon Pender, an Associate Director at GVSC Materials Engineering, noted the synergy of the partnership, which combines the Army’s deep expertise in vehicle technology with Velo3D’s industry-leading position in advanced manufacturing. This joint effort is designed to accelerate the adoption of qualified 3D-printed parts, directly addressing known supply chain vulnerabilities.

Echoing this sentiment, Dr. Arun Jeldi, CEO of Velo3D, expressed pride in the company’s role as the first US-based OEM with domestic PBF-LB technology to formally support the Army’s ground vehicle supply chain. He emphasized that Velo3D’s solutions are engineered to deliver not just faster part availability and enhanced reliability, but also the critical surge capacity required to meet defense demands in times of crisis. The collaboration represents a shared commitment to modernizing military sustainment for a new era of strategic competition.

Blueprint for a Resilient Future: The Strategic Impact of On-Demand Production

The integration of additive manufacturing represents more than just a new way to make parts; it signals a fundamental shift in military logistics and sustainment philosophy. By creating a digital inventory of qualified part files, the Army can move toward a distributed manufacturing model. Instead of shipping physical components across the globe, it can transmit a data file to a 3D printer located at a forward operating base, a maintenance depot, or a stateside arsenal, producing the needed part in hours or days, not months.

This on-demand capability fundamentally transforms the supply chain from a reactive pipeline into a proactive and resilient network. It reduces the need for vast physical inventories, shortens repair cycles, and enhances the self-sufficiency of deployed units. The ability to rapidly prototype and produce improved or obsolete parts in the field provides a significant tactical advantage. Through this forward-thinking initiative, the Army is building a more agile and robust support system, one where the readiness of its combat fleet is secured by digital blueprints and powdered metal, not by a long and vulnerable chain of physical goods.