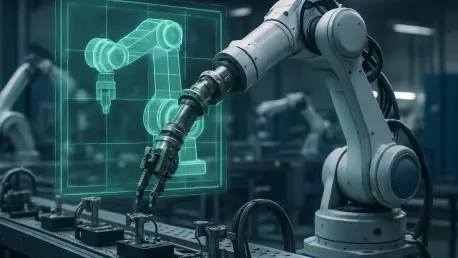

In the fast-evolving landscape of industrial automation, a groundbreaking technology is capturing attention for its potential to redefine how robots interact with complex environments, promising a future where precision and adaptability are paramount. Imagine a manufacturing floor where robots not only see in three dimensions but also adapt dynamically to unpredictable changes, performing tasks with human-like precision at unprecedented speeds. This is the promise of 4D Vision technology, a cutting-edge innovation that integrates artificial intelligence with advanced visual systems to revolutionize industrial robotics. As manufacturers worldwide grapple with rising demands for efficiency and flexibility, the emergence of such technology could be the key to unlocking new levels of productivity. With significant investments pouring into this field and major industry players adopting these solutions, the question arises whether this advancement can truly transform automation standards. This article delves into the intricacies of 4D Vision, exploring its capabilities, the driving forces behind its adoption, and its potential impact on the future of manufacturing.

Breaking New Ground with 4D Vision Technology

The foundation of 4D Vision lies in its ability to transcend traditional 3D vision systems by incorporating an AI-driven layer that acts as a fourth dimension of adaptability. This technology enables industrial robots to tackle intricate tasks such as bin picking, de-racking, and complex assembly with remarkable speed and accuracy, even in challenging conditions like shifting containers or inconsistent lighting. Unlike conventional systems that often struggle with variability, this innovative platform dynamically adjusts to real-time changes, ensuring reliability in high-stakes environments. Recent enhancements, including no-code setup tools and AI-powered calibration, have further simplified deployment, allowing manufacturers to integrate advanced automation without extensive technical expertise. By reducing setup times and improving operational efficiency, this technology addresses long-standing barriers to robotic adoption in industrial settings, paving the way for broader implementation across diverse sectors.

Moreover, the practical applications of 4D Vision extend beyond mere functionality to redefine performance benchmarks in manufacturing. Robots equipped with this technology can handle worn or damaged equipment without faltering, a capability that significantly minimizes downtime and maintenance costs. The real-time diagnostics embedded in the system provide continuous feedback, enabling proactive adjustments that maintain optimal performance under varying conditions. This adaptability is particularly crucial in industries like automotive manufacturing, where precision and speed are non-negotiable. As a result, companies adopting this solution report substantial improvements in throughput and error reduction, demonstrating a clear competitive edge. The seamless integration of such advanced features suggests that 4D Vision could become a cornerstone of next-generation automation, fundamentally altering how industrial processes are designed and executed in dynamic production environments.

Financial Backing and Strategic Growth

A significant indicator of the potential of 4D Vision technology is the robust financial support it has garnered, reflecting strong investor confidence in its transformative capabilities. A leading company in this space recently closed an oversubscribed Series A funding round, with substantial contributions from prominent venture capital firms focused on industrial innovation. This influx of capital is earmarked for critical areas such as talent acquisition, process optimization, and further development of the 4D Vision platform. The funding comes on the heels of nearly tripled year-over-year revenue growth, underscoring the surging demand for intelligent automation solutions in manufacturing. Serving a wide array of clients, including major North American automotive manufacturers and numerous industrial firms, the technology’s proven impact is evident. This financial milestone positions the technology for accelerated growth, promising to expand its reach and refine its offerings to meet evolving industry needs.

In parallel with financial achievements, strategic moves to bolster leadership and market presence highlight the commitment to scaling this innovation. The appointment of seasoned executives in key roles such as global sales, marketing, finance, and human resources brings a wealth of experience in navigating high-growth tech landscapes. These leaders are tasked with steering the company toward deeper customer engagement and operational excellence. Plans to double the sales team and establish a new office in a major manufacturing hub further demonstrate an intent to strengthen ties with key industrial markets. Such geographic expansion ensures closer collaboration with clients, facilitating tailored solutions that address specific automation challenges. Together, these efforts signal a comprehensive strategy to not only sustain momentum but also solidify a leadership position in the rapidly evolving field of robotic automation over the coming years.

Industry Perspectives and Future Implications

Stakeholder insights reveal a unified belief in the game-changing potential of 4D Vision for vision-guided robotics. Industry experts and investors alike view this technology as a pivotal advancement, capable of driving significant economic growth through enhanced industrial innovation. Venture capital leaders have emphasized the importance of supporting hard tech solutions that address critical manufacturing bottlenecks, positioning 4D Vision as a catalyst for widespread automation adoption. Company executives echo this sentiment, expressing optimism about scaling operations to solve previously intractable challenges in robotic task execution. Marketing leaders stress the need to make AI-driven tools intuitive for engineers, ensuring accessibility across skill levels. These perspectives collectively underscore a shared vision of setting new industry standards, where advanced perception transforms robots into indispensable partners on the factory floor, reshaping operational paradigms.

Looking ahead, the implications of 4D Vision extend to redefining the competitive landscape of industrial automation. As more manufacturers recognize the value of robots that can adapt in real time to complex scenarios, the demand for such technology is expected to surge. This shift could spur further innovation, encouraging the development of complementary tools and systems that enhance robotic capabilities. The focus on user-friendly interfaces and rapid deployment also suggests a future where automation is democratized, accessible to smaller enterprises previously deterred by cost or complexity. Industry observers anticipate that over the next few years, from now until 2027, the integration of AI with vision systems will become a benchmark for robotic solutions, pushing competitors to innovate or risk obsolescence. This trajectory indicates that 4D Vision may not just transform automation but could fundamentally alter the manufacturing ecosystem, fostering efficiency on a global scale.

Reflecting on a Path Forward

Reflecting on the strides made with 4D Vision technology, it becomes clear that the journey has already reshaped key aspects of industrial robotics by addressing core challenges in adaptability and precision. The successful funding rounds and strategic expansions lay a solid foundation for scaling impact across manufacturing sectors. Leadership enhancements and stakeholder endorsements further validate the technology’s role as a disruptor in automation standards. Looking back, the focus on practical, AI-driven solutions proved instrumental in gaining traction among major industry players. Moving forward, the emphasis should shift toward continuous innovation and broader accessibility, ensuring that even smaller manufacturers can leverage these advancements. Exploring partnerships and investing in training programs to upskill workforces might be the next logical step, alongside refining diagnostic tools to anticipate future needs. These actions would cement the legacy of 4D Vision as a cornerstone of industrial progress, guiding the sector toward a more automated, efficient horizon.