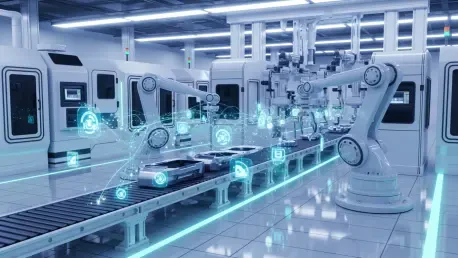

Vietnam’s manufacturing sector, a cornerstone of its economic ascent, now stands at a critical inflection point where its traditional advantages are being challenged by the relentless pace of global innovation and shifting market dynamics. The nation’s factories, long powered by a diligent workforce, are confronting a confluence of formidable pressures, including persistent skilled labor shortages, the volatility of international supply chains, and increasingly shorter product life cycles that demand unprecedented agility. Compounding these issues is a growing consumer appetite for highly personalized products, a trend that traditional mass-production models struggle to accommodate. This complex environment has created an urgent imperative for a paradigm shift, pushing enterprises to look beyond conventional methods and toward the transformative potential of digitalization and artificial intelligence to maintain their competitive edge and secure a more resilient and prosperous future in the global value chain.

A Strategic Response to Industry Pressures

The Launch of a Specialized AI Initiative

In a direct response to the mounting challenges confronting the nation’s industrial base, technology firm NTQ recently announced the formal establishment of a new subsidiary, NTQ Factory, dedicated exclusively to smart factory solutions. The launch event, held on December 10th, drew significant attention from a broad spectrum of stakeholders, including manufacturing executives, prominent industry organizations, and key government agencies, underscoring a widespread consensus on the necessity of digital acceleration. The initiative was framed as an essential solution for Vietnamese manufacturers grappling with operational hurdles. These enterprises face a difficult landscape characterized by a shrinking pool of skilled labor, the need for rapid adaptation to fluctuating product demands, and the inherent fragility of global supply networks. NTQ Factory aims to provide concrete consulting and implementation services for advanced AI-powered systems, positioning itself as a crucial enabler for companies seeking to navigate this new industrial era and enhance their operational resilience and market responsiveness.

An Integrated Ecosystem for Smart Manufacturing

At the heart of NTQ Factory’s value proposition lies a comprehensive and modular digital transformation ecosystem, engineered to function on a unified, interconnected platform. This sophisticated solution is meticulously designed to address the core inefficiencies that hinder modern production facilities. Its capabilities include real-time, automated data collection directly from the factory floor, which eliminates manual errors and provides an instantaneous, accurate view of all processes. The system facilitates constant machine-status monitoring, enabling predictive maintenance and minimizing costly downtime. Furthermore, it generates detailed operational reports that offer deep insights into performance metrics, bottlenecks, and areas for improvement. A key feature is its AI-assisted production planning module, which analyzes vast datasets to optimize schedules, allocate resources effectively, and adapt dynamically to unforeseen changes. The ultimate objective of this integrated approach is to significantly enhance operational efficiency, foster a more connected and data-driven manufacturing environment, and elevate the overall competitiveness of Vietnamese enterprises.

Differentiating Through Expertise and Partnership

Leveraging Global Experience for Local Application

A significant differentiator for the new initiative is its foundation of deep, practical expertise, built upon the extensive experience of its parent company. Leveraging over 14 years of NTQ’s work in the technology sector, the specialized team behind the smart factory solutions brings a wealth of knowledge gained from implementing complex systems in large-scale factories across highly competitive international markets. This global exposure, with successful projects in Japan, South Korea, and various European nations, has imbued the team with an understanding of world-class standards and best practices. However, this international perspective is carefully balanced with an in-depth comprehension of the unique challenges and opportunities within the Vietnamese market. This dual focus allows NTQ Factory to deliver solutions that are both standardized for reliability and highly flexible, enabling rapid and tailored deployment for manufacturers of all scales. This ability to translate global innovation into practical, localized applications is central to its strategy for driving meaningful change in the sector.

Fostering Long-Term Digital Transformation

Beyond its role as a technology provider, NTQ Factory is strategically positioned as a long-term collaborative partner committed to guiding clients through the complexities of their digital transformation journeys. This approach extends past the initial implementation of software and hardware, encompassing ongoing advisory services to ensure that manufacturers can continuously adapt and optimize their operations in a rapidly evolving technological landscape. The establishment of this subsidiary is a pivotal element within NTQ’s broader corporate growth strategy. It represents a deliberate move to diversify the company’s portfolio of digital solutions, significantly strengthen its organizational capacity, and advance toward major corporate milestones. This strategic initiative is intertwined with the company’s ambitions for substantial workforce expansion and its long-term goal of a future Initial Public Offering (IPO), signaling a deep and sustained commitment to spearheading the adoption of smart manufacturing technologies and solidifying its leadership position in the market.

A New Blueprint for Vietnamese Industry

The formal introduction of this dedicated smart factory initiative marked a significant development for Vietnam’s industrial sector. It represented a tangible and sophisticated response to the operational pressures that had begun to challenge the country’s manufacturing competitiveness on the global stage. The subsequent adoption of these integrated, AI-driven systems by forward-thinking enterprises established a new performance benchmark. This move effectively illustrated how leveraging real-time data analytics, predictive maintenance, and optimized production planning could unlock substantial gains in efficiency and adaptability. Consequently, this created a ripple effect across the industry, compelling other manufacturers to reevaluate their own technological capabilities and reconsider their long-term investment strategies. The launch was not merely the debut of a new service provider; it became a catalyst that accelerated the conversation around digitalization and set in motion a broader, more urgent push toward the factory of the future.